Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

The year 2025 is poised to witness transformative developments in the realm of Tungsten Carbide Alloy applications and innovations. As industries continually seek materials that combine exceptional durability, hardness, and versatility, Tungsten Carbide Alloy stands out as a leading choice for a multitude of applications. From aerospace engineering to construction and mining, the unique properties of this remarkable alloy enable breakthroughs that drive efficiency and enhance performance across various sectors.

In the next few years, we can expect significant advancements in the processing techniques and applications of Tungsten Carbide Alloy. Innovations in manufacturing processes are likely to improve material characteristics, leading to lighter, stronger, and more cost-effective solutions. Additionally, the growing emphasis on sustainability will guide research and development efforts, promoting the use of Tungsten Carbide Alloy in green technologies and environmentally friendly applications. As we delve into the top trends shaping the future of Tungsten Carbide Alloy, it becomes evident that its potential is limited only by our creativity and commitment to harnessing its capabilities for the betterment of industries worldwide.

Tungsten carbide alloys are renowned for their remarkable hardness and durability, making them a preferred choice across various industrial applications. These alloys primarily consist of tungsten and carbon, which form a dense composite that can withstand extreme wear and tear. Their resistance to scratching, deformation, and abrasion positions them as ideal materials for cutting tools, mining equipment, and manufacturing processes that require high precision. The unique properties of tungsten carbide alloys also enable them to maintain their integrity even in high-temperature conditions, further enhancing their performance in challenging environments.

In addition to their exceptional hardness, tungsten carbide alloys offer significant benefits in terms of longevity and cost-effectiveness. They reduce the frequency of tool changes and repairs, which can lead to decreased downtime in manufacturing and production settings. Furthermore, their resilience translates to lower overall material consumption, as components made from tungsten carbide require less frequent replacement. This not only contributes to operational efficiency but also aligns with sustainability goals by minimizing waste. As industries continue to innovate, the emphasis on utilizing tungsten carbide alloys will undoubtedly expand, showcasing their key characteristics and benefits in enhancing productivity and reliability across diverse applications.

Tungsten carbide, known for its exceptional hardness and wear resistance, finds extensive applications across various industries. In metallurgy, it is primarily used for cutting tools, allowing manufacturers to produce high-precision parts that endure heavy wear. The aerospace sector also benefits from tungsten carbide, as it is utilized in components that require durability and strength under extreme conditions, such as turbine blades and die components. Additionally, the oil and gas industry employs tungsten carbide in drilling equipment, enhancing the performance and lifespan of tools used in demanding environments.

In the realm of construction, tungsten carbide is utilized for making robust wear parts for machinery and tools, contributing significantly to efficiency and longevity. The material’s high resistance to impact and deformation makes it ideal for applications like road construction and excavation machinery. Furthermore, tungsten carbide is increasingly being integrated into additive manufacturing processes, allowing for the production of complex geometries that were previously challenging to achieve. As industries continue to explore innovations in material science, tungsten carbide remains a cornerstone in enhancing performance and driving advancements across multiple sectors.

Recent innovations in tungsten carbide alloys have significantly enhanced their performance across various industrial applications. With the global tungsten carbide market projected to reach USD 15.3 billion by 2025, driven by its increasing demand in sectors such as manufacturing, mining, and aerospace, the focus on improving the material's properties is paramount. New formulations and processing techniques are being developed to increase the hardness and wear resistance of tungsten carbide alloys, addressing the critical need for longevity and reliability in extreme environments.

One groundbreaking advancement is the incorporation of advanced nanoparticles into the carbide matrix, which has shown to enhance toughness and resistance to thermal shock. This innovation not only improves the mechanical properties but also extends the service life of components made from tungsten carbide, providing a more economical option for industries that demand high-performance materials. According to a report from the Global Tungsten Market Analysis, these innovations have resulted in a performance increase of up to 30% in specific applications, making tungsten carbide alloys increasingly attractive for high-demand scenarios.

Furthermore, additive manufacturing techniques are gaining traction, allowing for more complex geometries and customized solutions that traditional processes may not achieve. This flexibility is critical in tailoring tungsten carbide parts to meet specific performance criteria and improving resource efficiency. As these trends unfold, the ongoing research in enhancing the thermal and chemical stability of tungsten carbide alloys will likely catalyze further innovations, setting the stage for even broader application possibilities in future industries.

The landscape of tungsten carbide alloy applications is evolving rapidly, driven by ongoing innovations in material science and engineering practices. Future trends indicate a significant shift towards enhanced performance in extreme conditions, enabling tungsten carbide to be utilized in areas previously deemed unfeasible. Advanced manufacturing techniques such as additive manufacturing and precision machining are expanding the design possibilities, facilitating the creation of complex geometries and optimizing material usage. This adaptability not only improves product longevity but also opens doors to new applications, particularly in industries like aerospace and energy.

Moreover, the integration of smart technologies within tungsten carbide applications is set to redefine industry standards. The adoption of IoT and smart monitoring systems allows for real-time data collection, leading to improved predictive maintenance and operational efficiency. This tech-driven approach enhances the reliability of components made from tungsten carbide, ensuring they can withstand rigorous demands while minimizing unexpected downtime. As industries seek to enhance productivity and reduce costs, these innovations will play a pivotal role in shaping the future landscape of tungsten carbide applications, ushering in a new era of performance and sustainability.

| Trend | Description | Application Area | Innovation Type | Projected Impact |

|---|---|---|---|---|

| Increased Demand for Wear Resistance | Growing industries require materials that can withstand high wear rates. | Mining, Manufacturing | Material Science Innovations | Enhanced product lifespan and reduced costs. |

| Advancements in Additive Manufacturing | Utilizing 3D printing for complex tungsten carbide parts. | Aerospace, Automotive | Process Innovation | Reduction in material waste and enhanced design flexibility. |

| Sustainability in Production | Innovative recycling processes for tungsten carbide scrap. | Construction, Oil & Gas | Environmental Innovation | Lower carbon footprint and reduced raw material dependency. |

| Smart Coatings Development | Creating coatings that adapt to environmental changes. | Defence, Electronics | Technological Innovation | Improved functional performance and safety. |

| Enhanced Shock Resistance | Innovations that improve toughness of tungsten carbide. | Heavy Machinery, Mining | Material Engineering | Safer operations and higher productivity. |

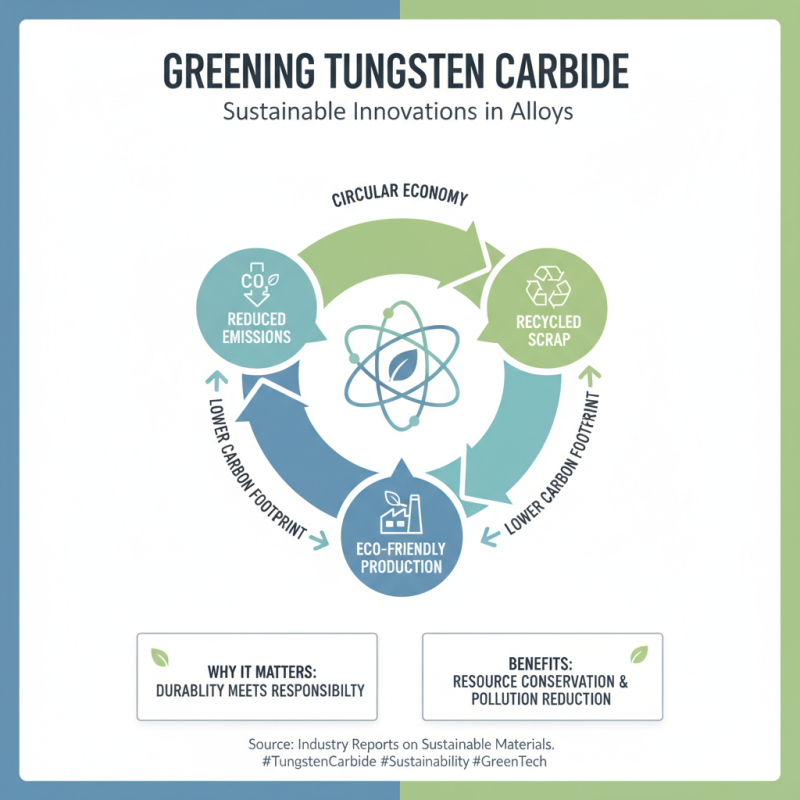

With increasing scrutiny on sustainability, the tungsten carbide alloy sector is witnessing innovative changes aimed at minimizing environmental impact. Tungsten carbide, known for its durability and high-performance characteristics, is integral to various industries. However, the extraction and processing of tungsten pose environmental challenges, prompting a shift toward more sustainable practices. Companies are exploring ways to recycle tungsten carbide scrap and incorporate eco-friendly practices into production, significantly reducing waste and carbon footprints.

Tips for Sustainability: One effective strategy is to prioritize suppliers that emphasize sustainable tungsten sourcing. By ensuring that your supply chain uses recycled materials or ethically mined tungsten, you support responsible practices. Additionally, consider engaging in initiatives that promote recycling within your industry. This not only aids in reducing the demand for new materials but also encourages a circular economy approach to tungsten carbide usage.

The exploration of alternative materials is another critical trend gaining traction. Researchers are actively looking into substitutes that could match the performance of tungsten carbide while presenting a lower environmental burden. As innovations unfold, it's essential for businesses to remain adaptable, embracing new technologies and processes that support sustainability. By aligning operations with sustainable practices, the tungsten carbide industry can pave the way for a greener future while maintaining its legacy of strength and resilience.