Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

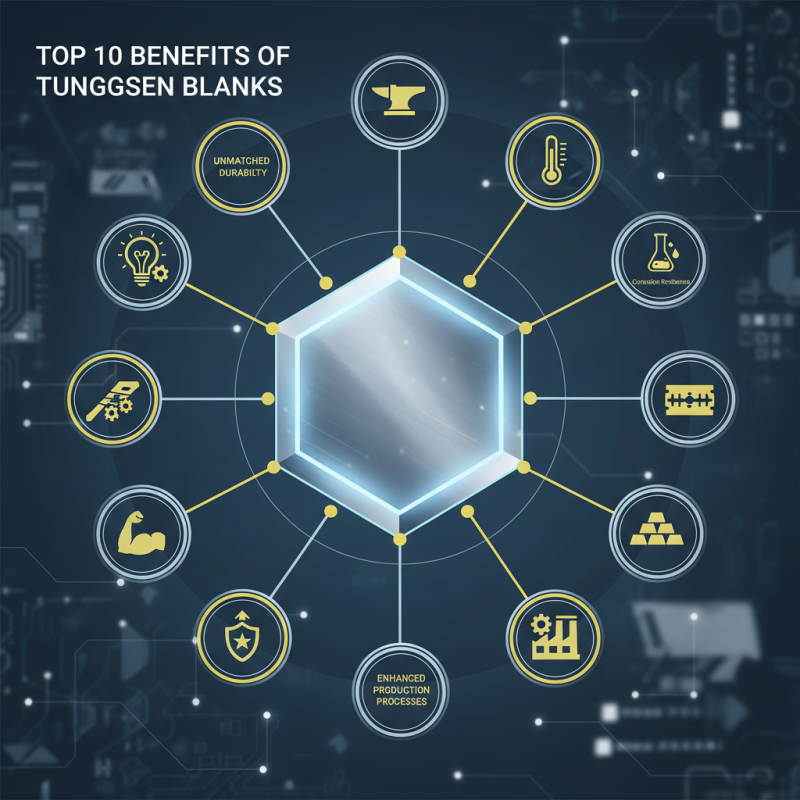

In the realm of metalworking and manufacturing, "Tungsten Blank" has emerged as a pivotal material due to its impressive properties and versatility. According to Dr. Emily Carter, a leading expert in material science, "Tungsten Blanks offer unmatched durability and precision, making them indispensable in a variety of industrial applications." This statement encapsulates the growing recognition of tungsten blanks among engineers, machinists, and manufacturers striving for excellence in their crafts.

The top benefits of tungsten blanks stretch beyond just resilience; they encompass aspects such as thermal stability, corrosion resistance, and the ability to maintain sharp edges and precision in tooling. As industries continue to demand high-performance materials, understanding the myriad advantages of tungsten blanks becomes crucial for those looking to enhance their production processes. With its remarkable density and strength, tungsten has rightly earned its place as a go-to material, setting a standard that others in the field strive to meet.

As we delve deeper into the top 10 benefits of tungsten blanks, it becomes clear that this remarkable material is not just a choice, but rather a strategic imperative for professionals dedicated to innovation and quality in manufacturing.

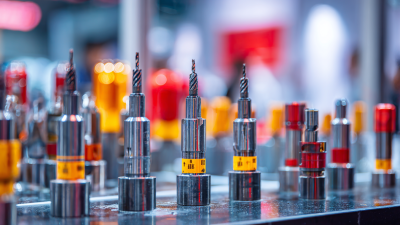

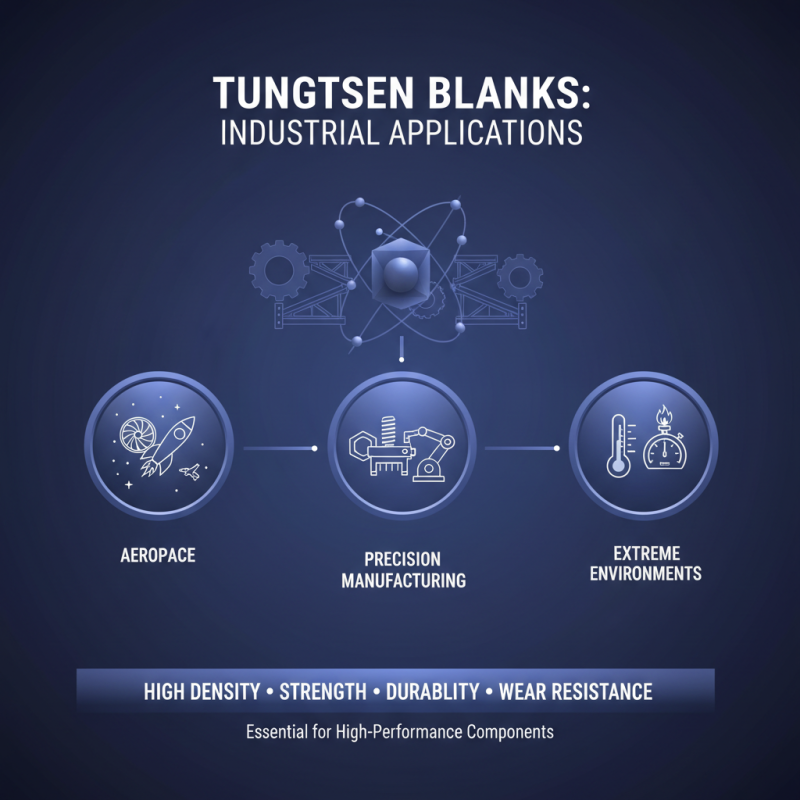

Tungsten blanks have gained significant traction in various industries due to their unique properties, making them an essential material for many applications. In the manufacturing sector, tungsten's high density and strength make it ideal for producing durable components that require precision and longevity. For example, tungsten blanks are frequently utilized in the aerospace industry for parts that must withstand extreme temperatures and pressures. Their remarkable resistance to wear and tear ensures longevity, thereby reducing maintenance costs and enhancing performance.

In the field of electronics, tungsten blanks are invaluable for their excellent conductivity and thermal stability. They are commonly used in the production of filaments and electrical contacts, which require materials that can handle high levels of heat and electrical flow without degrading. Additionally, tungsten's ability to be machined into intricate shapes allows for the manufacturing of complex electronic components that meet the precise requirements of modern technology. Overall, the versatility and resilience of tungsten blanks make them a vital resource across multiple sectors, driving innovation and efficiency in contemporary manufacturing practices.

Tungsten blanks are recognized for their remarkable durability and strength, making them an ideal choice in various applications, from jewelry to industrial use. The density of tungsten contributes to its robust nature, ensuring that products made from it can withstand significant wear and tear. This characteristic not only enhances the longevity of items but also maintains their aesthetic appeal, as tungsten is less prone to scratches and dents compared to softer materials.

When working with tungsten blanks, it's essential to consider a few tips to maximize their potential. First, invest in quality tools specifically designed for cutting and shaping tungsten, as standard tools may not yield optimal results. Additionally, always wear protective gear, including gloves and eyewear, when handling tungsten to prevent injury from sharp edges or particles.

Another important tip is to keep the work area clean and well-lit. Tungsten can generate fine dust during the machining process, which can be harmful if inhaled. Maintaining a tidy workspace helps in safely managing the material and ensuring that you achieve precise and clean cuts, ultimately enhancing the quality of the finished product. By acknowledging and leveraging the key characteristics of tungsten blanks, you can create durable and elegantly designed items that stand the test of time.

Tungsten blanks have garnered attention in various industries for their remarkable cost-effectiveness compared to traditional materials. Recent industry reports indicate that tungsten offers a density depth of approximately 19.3 g/cm³, which is significantly higher than other common metals like lead (11.34 g/cm³) and steel (7.85 g/cm³). This high density allows manufacturers to achieve the desired weight with less material, ultimately reducing overall production costs. Due to its malleability, tungsten can be efficiently processed into blanks without extensive waste, a factor that enhances its cost efficiency in manufacturing applications.

Furthermore, tungsten blanks excel in durability, which contributes to their long-term value. A study published by the International Journal of Advanced Manufacturing Technology highlights that tungsten exhibits unparalleled resistance to wear and deformation, leading to decreased replacement frequencies. This durability allows industries to save on maintenance and replacement costs, which are often substantial with materials that wear out quickly. As a result, although the initial investment in tungsten may be slightly higher, the overall lifecycle cost proves to be lower when factoring in extended service life and reduced operational expenditures. This economic advantage makes tungsten blanks an increasingly attractive choice for businesses seeking quality and efficiency in their production lines.

Tungsten blanks have emerged as a crucial component in precision engineering, thanks to their exceptional properties such as high density, strength, and thermal stability. In industries ranging from aerospace to automotive, tungsten blanks are used to create components that require meticulous precision and durability. According to recent industry reports, the demand for high-quality tungsten materials is projected to grow by over 5% annually, indicating a robust interest in their applications in precision engineering. These materials excel in manufacturing intricate parts for cutting tools, molds, and weights, showcasing their versatility and reliability.

Tips: When selecting tungsten blanks for precision engineering projects, it’s essential to evaluate the specific mechanical properties required for your application. Conducting a thorough analysis of the project's demands will ensure you choose the most suitable tungsten grade, enhancing the overall performance of the finished product.

Moreover, tungsten's adaptability allows it to be processed into various forms, including rods, sheets, and custom shapes, making it indispensable for specialized engineering applications. With advancements in machining technologies, the efficiency and accuracy of tungsten production continue to improve, further solidifying its role in high-performance engineering contexts. Understanding the unique benefits of tungsten blanks empowers engineers to innovate and optimize designs for a wide range of applications, ultimately driving industry standards higher.

| Benefit | Description | Application |

|---|---|---|

| High Density | Tungsten blanks are extremely dense, making them ideal for applications requiring weight and stability. | Counterweights in machinery |

| Durability | Tungsten blanks are highly resistant to wear and tear, ensuring longevity in challenging environments. | Cutting tools |

| Heat Resistance | They can withstand extremely high temperatures without losing structural integrity. | High-temperature furnaces |

| Corrosion Resistance | Tungsten blanks resist corrosion, making them suitable for harsh chemical environments. | Chemical processing machinery |

| Precision Machining | Tungsten blanks allow for precise cutting and machining, essential in engineering. | Manufacturing of precision instruments |

| Versatility | They can be machined into various shapes and sizes for multiple applications. | Custom parts for various industries |

| Low Thermal Expansion | Tungsten blanks maintain their shape under varying temperatures. | Precision alignments in aerospace applications |

| Eco-Friendliness | Tungsten is a sustainable material that can be recycled without losing its properties. | Sustainable manufacturing processes |

| Radiation Shielding | Due to its high density, tungsten is effective in blocking radiation. | Nuclear and medical applications |

| Cost-Effectiveness | The longevity and durability of tungsten blanks lead to lower long-term costs in manufacturing. | High-volume production processes |

The environmental impact and sustainability of tungsten blanks have become critical topics in today's manufacturing and industrial sectors. As industries pivot towards more sustainable practices, tungsten blanks are emerging as a viable option due to their remarkable durability and recyclable nature. Reports indicate that tungsten, being one of the hardest metals, requires less frequent replacement than other materials, subsequently reducing the energy and resources spent in production and disposal. A study published by the International Tungsten Industry Association highlights that utilizing tungsten can lead to a 30% decrease in material waste over time when compared to conventional raw materials.

Moreover, the production process of tungsten blanks has seen significant advancements aimed at reducing ecological footprints. Innovative mining and fabrication techniques are being adopted to minimize emissions and preserve local ecosystems. According to a sustainability report by the World Materials Forum, the tungsten supply chain's emphasis on responsible sourcing practices has decreased the overall carbon emissions associated with mining activities by approximately 20% over the past decade. As the demand for sustainable materials grows, the environmental benefits of tungsten blanks position them as not just industrial tools but also as contributors to eco-friendly manufacturing and practices.