Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

Tungsten Carbide Inserts are essential tools in modern manufacturing. These inserts are used in various machining applications. Their durability and strength set them apart from other materials. According to industry reports, Tungsten Carbide Inserts can increase tool life by up to 500%. This efficiency offers a significant cost advantage to manufacturers.

The unique properties of Tungsten Carbide contribute to its growing popularity. Its hardness allows for precise cutting, even in tougher materials. However, while the benefits are clear, some challenges remain. Handling and replacing these inserts can be complex. Additionally, the initial investment is often higher than other options.

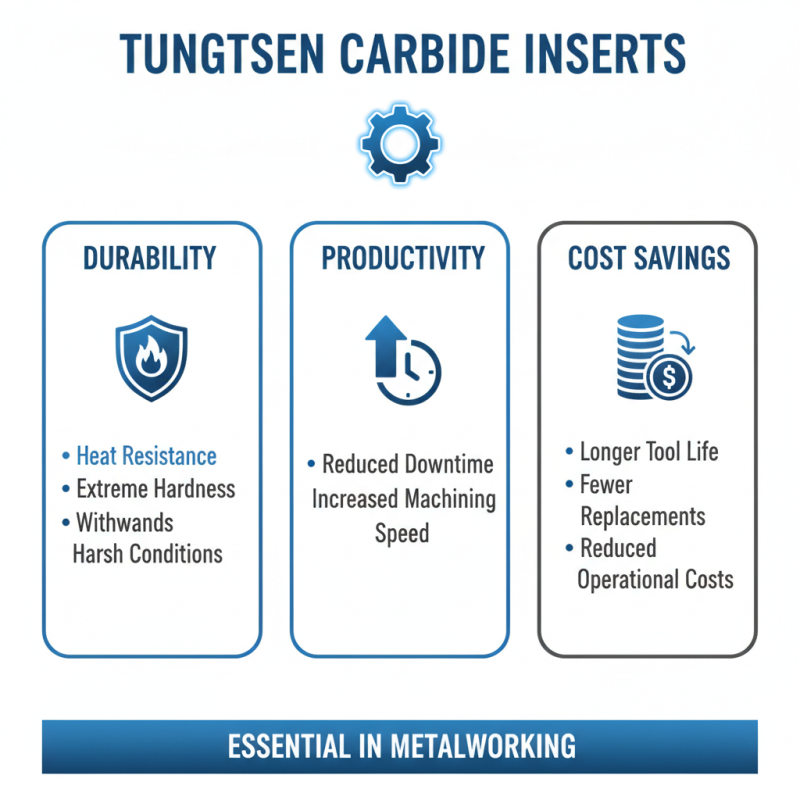

However, the long-term savings and improved performance often outweigh these considerations. Industries utilizing Tungsten Carbide Inserts report reduced downtime and higher productivity rates. Advanced machining processes benefit significantly, and it’s worth noting that not all applications maximize these advantages. Exploring how to integrate these inserts for optimal results is crucial for every manufacturer.

Tungsten carbide inserts have become essential in metalworking applications due to their impressive durability. They are known for their heat resistance and hardness. This allows them to withstand the harshest conditions during machining. As a result, they increase productivity by reducing downtime. The longevity of these inserts minimizes the frequency of replacements, saving costs in the long run.

In addition to their strength, tungsten carbide inserts provide excellent cutting performance. They allow for precise cuts, producing smooth finishes on metal surfaces. This precision can be a game changer in industries where detail matters. However, using them requires careful handling and setup. Improper use can lead to premature wear. It’s crucial to match them with the right tools to maximize their effectiveness.

Despite their benefits, there are challenges. They can be brittle under certain conditions, making them prone to chipping. This may lead to waste and inefficiency. It's essential to assess your specific needs before fully committing to tungsten carbide inserts. Overall, while they offer great advantages, using them requires thoughtful consideration to avoid potential pitfalls.

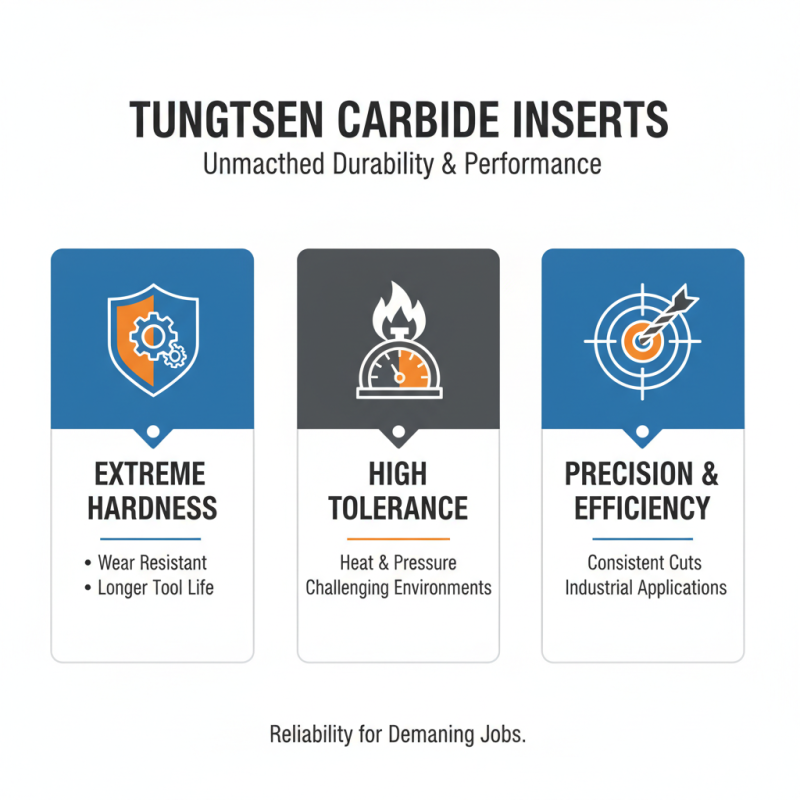

Tungsten carbide inserts are known for their enhanced durability and wear resistance. This material is incredibly hard, making it ideal for cutting and drilling applications. Unlike traditional tools, tungsten carbide can withstand high temperatures and pressures. This feature allows it to maintain its performance in challenging environments. Many industries rely on these inserts for precision and efficiency.

The wear resistance of tungsten carbide is particularly noteworthy. Inserts made from this material last longer than others. They reduce the frequency of replacements, which can save time and money. Operators often find themselves less frustrated during long machining processes. However, one must consider the balance between cost and longevity. Tungsten carbide can be more expensive initially, raising questions about its overall value.

Despite its strengths, some challenges exist. If not used correctly, tungsten carbide inserts can become damaged. Proper maintenance and care are crucial to ensure they perform at their best. Users must continually assess their tool choices and environments. The benefits of tungsten carbide inserts are evident, but it is essential to reflect on their proper application and care.

Tungsten carbide inserts are becoming popular due to their cost-effectiveness. These inserts are durable and provide significant long-term savings. Their hardness and resistance to wear mean they last longer than traditional materials. This reduces replacement frequency, leading to lower costs over time.

When using tungsten carbide inserts, consider proper installation. A well-set insert maximizes efficiency and extends tool life. Regular maintenance is essential for keeping them in good condition. Check for signs of wear to avoid potential issues.

Tip: Invest in quality tools designed for tungsten carbide. They enhance performance while ensuring more savings. Experiment with different angles and feeds for better results. Small adjustments can lead to noticeable improvements.

Tungsten carbide inserts are revolutionizing machining processes. They significantly enhance cutting performance. This material can withstand high temperatures and pressures. According to industry reports, inserts made from tungsten carbide can last up to 30 times longer than traditional steel tools. This makes them a preferred choice for many manufacturers.

Precision is another crucial advantage. Tungsten carbide inserts allow for tighter tolerances in machining. This means producing parts that fit together better, reducing waste. Data from machining studies show a 20% increase in precision when using these inserts. This improvement can lead to higher efficiency and reduced costs in production.

However, the initial investment in tungsten carbide can be high. Some shops hesitate due to upfront costs. It's essential to weigh the long-term benefits against these expenses. Not every application calls for tungsten carbide. Each situation requires careful evaluation. Understanding specific needs is key to making the right decision.

Tungsten carbide inserts are incredibly versatile. They find applications in multiple industries such as mining, construction, and manufacturing. Their durability and wear resistance make them ideal for cutting tools and high-pressure applications. In mining, they reduce wear on equipment, improving efficiency. This has a direct impact on productivity.

In the construction industry, tungsten carbide inserts aid in drilling and grinding operations. Their ability to maintain sharp edges helps workers complete tasks faster. However, not all inserts perform the same. Some might wear out too quickly or break under extreme conditions. This highlights the need for careful selection and testing.

Manufacturers often face challenges when integrating these inserts into production lines. Each machine has specific requirements. Sometimes, the inserts may not fit perfectly. This can lead to inefficiencies and increased costs. A thoughtful approach to choosing the right insert can mitigate these risks. Understanding the unique demands of each application is essential for maximizing benefits.