Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

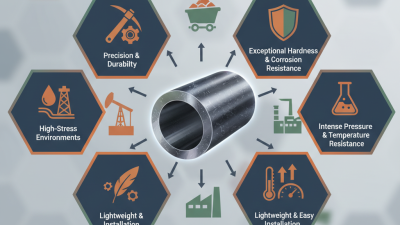

Tungsten Carbide Tube has emerged as a vital material in various industrial applications. Its unique properties make it a preferred choice for many sectors, such as mining, manufacturing, and construction. This tube's hardness and resistance to wear are unmatched. As industries continue to demand durability, tungsten carbide becomes increasingly essential.

However, while the benefits are impressive, using tungsten carbide tube also presents challenges. The initial cost can be high, making it a significant investment for businesses. Not all applications require such a robust material, leading some to question its necessity.

Despite these considerations, the advantages often outweigh the drawbacks. Industries report increased efficiency and reduced maintenance costs. The longevity of tungsten carbide tubes can translate into savings over time. As companies explore sustainable practices, choosing durable materials like tungsten carbide is a thoughtful reflection on resource use. Ultimately, the decision to utilize tungsten carbide tube should align with specific needs and long-term goals.

In industrial environments, tungsten carbide tubes offer numerous advantages. These tubes are known for their exceptional hardness, making them ideal for high-wear applications. Their ability to withstand extreme conditions sets them apart from other materials. For instance, when subjected to harsh temperatures or abrasive substances, tungsten carbide maintains its integrity better. This reliability can lead to fewer equipment failures, but it’s crucial to assess the specific needs of your application.

Additionally, tungsten carbide tubes are incredibly versatile. They can be used in different sectors, from mining to manufacturing. Their lightweight nature makes them easier to handle compared to heavier alternatives. However, this material can be more expensive upfront, which can be a point of contention. Companies must weigh the long-term benefits against initial costs. The durability of tungsten carbide often translates to lower maintenance needs, reducing downtime. Assessing these factors requires careful consideration, as the investment can be significant for some operations.

Moreover, chrome content in some tungsten carbide variants adds to their corrosion resistance. While this enhances performance, it’s not without potential drawbacks. Manufacturers sometimes overlook the need for proper installation techniques. Poor installation can lead to premature failure or unsatisfactory performance. Attention to detail is vital in maximizing the benefits that tungsten carbide tubes offer in an industrial setting.

Tungsten carbide tubes offer exceptional durability and wear resistance, making them ideal for various industrial applications. Their superior hardness outperforms many traditional materials. This feature prevents rapid degradation, reducing downtime and maintenance costs. These tubes can withstand harsh environments, maintaining integrity under pressure. The longevity of tungsten carbide helps industries save money over time.

When using tungsten carbide, it’s essential to consider the environment. High temperatures and corrosive substances can impact performance. Regular inspections are needed to catch any signs of wear early. This proactive approach can prevent unexpected failures and ensure consistent operation.

It’s wise to think about the specific application for tungsten carbide tubes. Evaluate your needs thoroughly. Not every situation demands the highest grade, and using the right material for the job can save resources. Adjusting your specifications based on performance needs will enhance overall efficiency.

This chart illustrates the top 10 benefits of using tungsten carbide tubes in industrial applications, showcasing attributes like enhanced durability and wear resistance. Each benefit is represented as a percentage, indicating its significance in industrial usage.

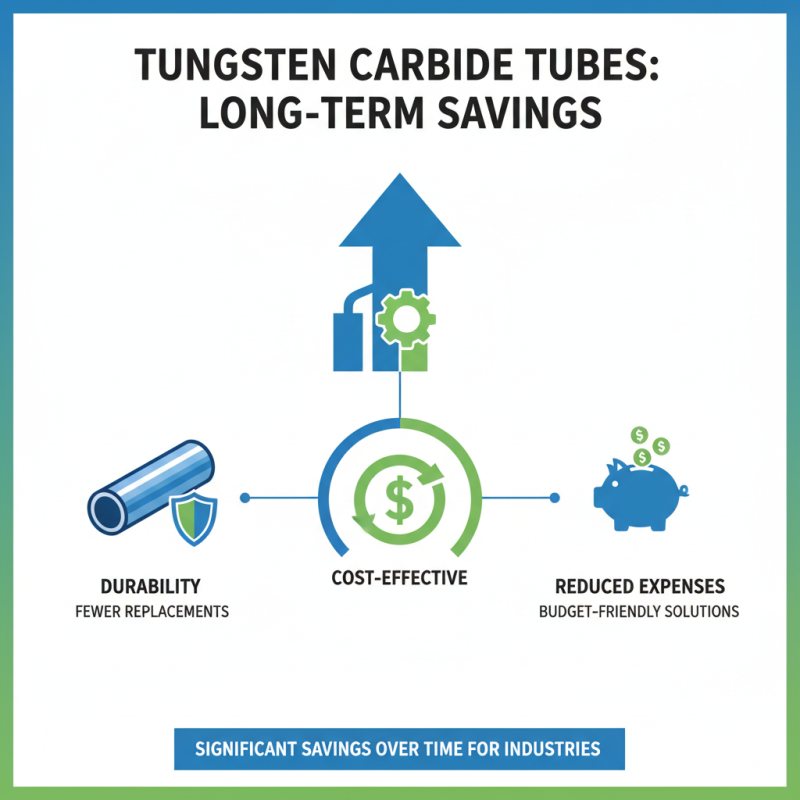

Tungsten carbide tubes are increasingly recognized for their cost-effectiveness in industrial applications. Their durability means fewer replacements, which directly impacts long-term expenses. Over time, companies save significant amounts of money. This is a crucial factor for industries constantly seeking budget-friendly solutions.

Another aspect to consider is maintenance. Tungsten carbide requires less frequent servicing. This reduces labor costs and downtime. However, it is essential to remember that initial investments can be higher compared to other materials. Companies must weigh this upfront cost against long-term benefits. Not every project will yield the same results.

Moreover, while tungsten carbide is highly durable, it is not indestructible. Industries must monitor wear and tear. Some challenges may arise in unexpected conditions, affecting efficiency. A thorough understanding of specific applications can help mitigate these risks. Balancing initial costs with lifespan is complex, and companies should constantly reflect on their choices.

Tungsten carbide tubes are increasingly popular in industrial applications due to their remarkable temperature and corrosion resistance. These tubes can withstand extreme temperatures up to 1,600°C. This makes them suitable for high-heat environments in industries like aerospace and automotive. Traditional materials often fail under such conditions, leading to costly downtime and maintenance.

Corrosion resistance is another significant advantage. Tungsten carbide can endure various aggressive chemicals, including acids and alkalis. A study from an industry group highlighted that tungsten carbide outperforms stainless steel in corrosive environments by over 30%. This longevity reduces replacement frequency, saving companies money and resources over time.

Tips: Always assess the specific needs of your applications. Not every situation demands extreme resistance. Choosing the right tube can optimize both cost and performance. Additionally, be mindful of handling tungsten carbide correctly. Its hardness can cause brittleness, leading to potential breaks if mishandled.

| Benefit | Description |

|---|---|

| Temperature Resistance | Tungsten carbide tubes can withstand extreme temperatures without deforming, making them suitable for high-heat applications. |

| Corrosion Resistance | These tubes are highly resistant to chemical corrosion, ensuring longevity in harsh environments. |

| Durability | Tungsten carbide has a high hardness value, providing superior wear resistance and durability. |

| Dimensional Stability | Maintains its shape under varying temperature conditions, ensuring stability during operation. |

| Machinability | Can be manufactured with precision, allowing for intricate designs and applications. |

| Lightweight | Despite its strength, tungsten carbide is lighter than many metals used for similar applications. |

| Electrical Conductivity | Provides good electrical conductivity, making it suitable for electronic applications. |

| Aggressive Wear Resistance | Exceptional performance in abrasive environments, extending the lifespan of equipment. |

| Cost-Effectiveness | Despite higher initial costs, reduces maintenance and replacement costs over time. |

| Versatility | Can be used in various industries, from oil and gas to manufacturing and aerospace. |

Tungsten carbide tubes are gaining traction across various industrial applications. Their durability makes them perfect for extreme environments. Industries like mining and oil drilling rely on these tubes. They withstand high pressures and abrasive materials. This resistance helps reduce downtime, crucial for productivity.

Manufacturing sectors also benefit immensely from tungsten carbide tubes. They are used in machining tools and cutting equipment. Their hardness ensures longer tool life, which saves costs. Additionally, they are suitable for applications that require precision. However, selecting the right specifications can be challenging. Mismatched dimensions might lead to inefficiencies in production.

Aerospace and automotive industries have found innovative uses for tungsten carbide tubes. They can enhance performance in critical components. The lightweight nature is a significant advantage. However, the high cost is a factor that requires careful consideration. Choosing the right grade is essential to avoid unexpected failures in demanding operations.