Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

In today's rapidly evolving manufacturing landscape, the adoption of cutting-edge materials and techniques is paramount for maintaining competitive advantage. One such material that has emerged as essential in modern production is Tungsten Tooling. Renowned for its exceptional hardness, high melting point, and wear resistance, tungsten plays a critical role in enhancing the precision and efficiency of manufacturing processes.

According to a recent report by the International Journal of Advanced Manufacturing Technology, the use of tungsten tooling can enhance tool life by up to 300%, significantly reducing downtime and operational costs. Additionally, a study by TechNavio forecasts that the global tungsten market will grow at a compound annual growth rate (CAGR) of 5.5% through 2025, underscoring the increasing recognition of tungsten's value in various industries. As manufacturers continue to seek ways to optimize productivity and quality, understanding the advantages of Tungsten Tooling becomes crucial for driving future innovations and operational excellence.

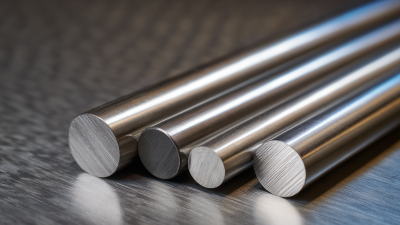

Tungsten tooling has emerged as a critical component in precision manufacturing processes, offering unique advantages that enhance production efficiency and product quality. One of the most significant benefits of tungsten tooling is its exceptional hardness and wear resistance. This characteristic allows for longer tool life, reducing the frequency of tool replacements and associated downtime in manufacturing operations. As a result, companies can maintain higher productivity levels and minimize costs related to tool maintenance.

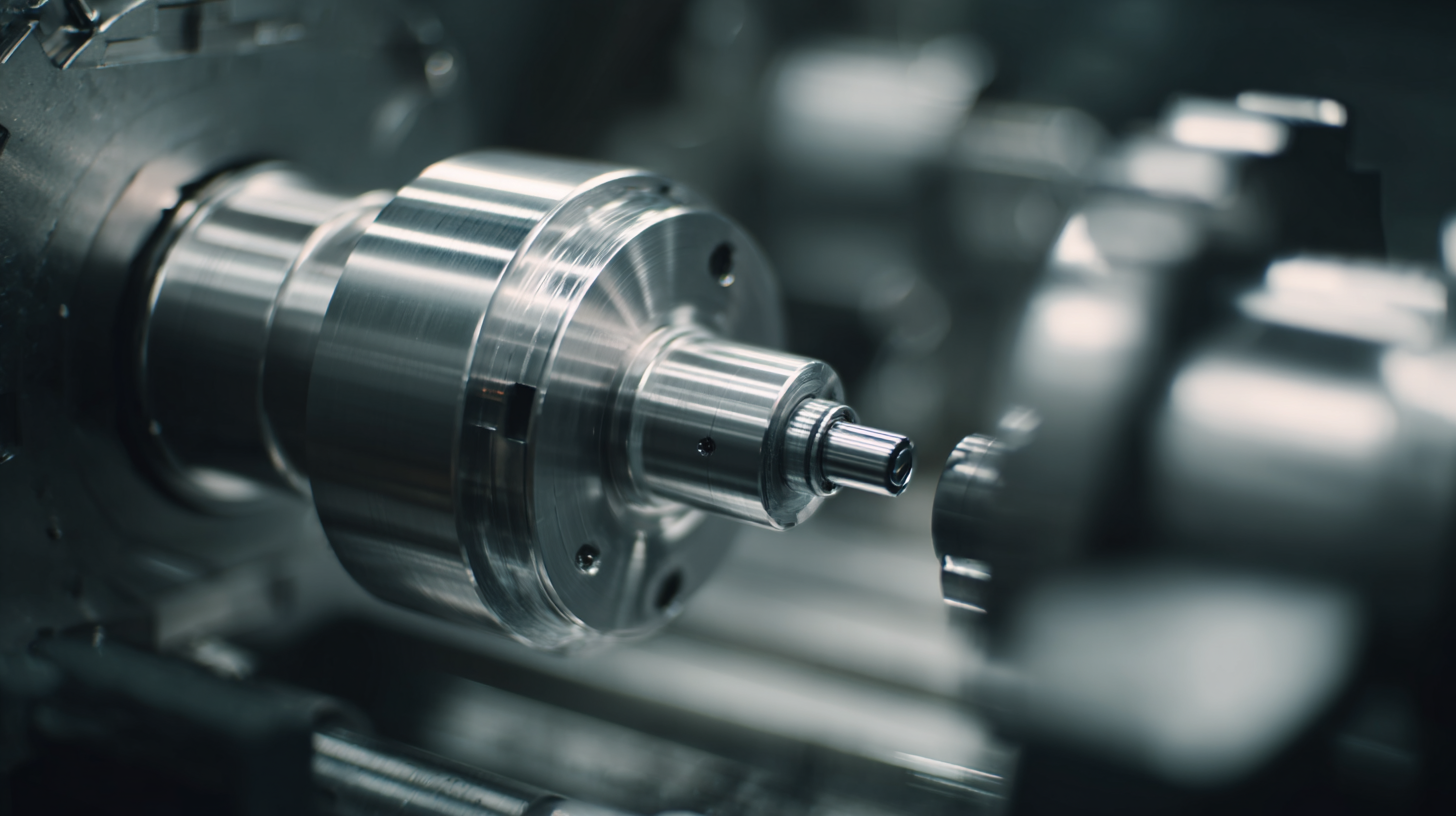

Moreover, tungsten tooling operates effectively at high temperatures, making it ideal for demanding applications that involve rigorous machining conditions. Its thermal stability ensures that tools maintain their sharpness and precision, leading to improved dimensional accuracy in manufactured parts. This precision is essential in industries where even minor deviations can lead to significant quality issues, such as aerospace and medical device manufacturing. Thus, the integration of tungsten tooling into modern manufacturing not only enhances operational efficiency but also contributes to the production of high-quality components that meet stringent industry standards.

Tungsten tooling has emerged as a game-changer in modern manufacturing techniques, primarily due to its superior properties compared to traditional tooling materials. When comparing tungsten to conventional materials like carbide or high-speed steel, tungsten showcases remarkable hardness and thermal resistance, enabling it to withstand higher temperatures and pressures without degrading. This results in longer tool life and reduced frequency of replacements, ultimately leading to cost savings for manufacturers and improved product quality.

**Tips:** When selecting tooling materials, consider the specific requirements of your manufacturing process, including the materials being worked on and the desired precision. Always evaluate the total cost of ownership, factoring in tool longevity and maintenance when comparing tungsten to traditional materials.

Furthermore, tungsten's excellent wear resistance makes it particularly suitable for high-performance applications. It is increasingly being used for precision machining, where a high degree of accuracy is necessary. As manufacturers continue to integrate advanced technologies, the shift toward tungsten tooling will likely accelerate, aligning with the demands for efficiency and sustainability in production environments.

**Tips:** Conduct regular assessments of your tooling performance to optimize the use of tungsten tools and ensure you are getting the best return on your investment. Exploring innovative machining techniques can also help maximize the benefits of tungsten tooling.

Tungsten tooling has emerged as a pivotal element in modern manufacturing techniques, especially in enhancing production efficiency and driving down costs. Recent industry reports reveal that manufacturers utilizing tungsten tools can achieve a 20-30% increase in production rates. This notable improvement is largely attributed to tungsten's superior hardness and resistance to wear, allowing for longer tool life and reduced downtime during operations. In fact, studies indicate that tools made from tungsten can last up to five times longer than traditional tool materials, directly translating to lower replacement costs and improved overall efficiency.

Tip: When considering tungsten tooling for your operations, assess the specific applications and materials being processed. This will help you identify the most effective tungsten tools that maximize performance and cost savings.

Tungsten tooling has emerged as a game-changer in modern manufacturing, showcasing its superior performance across various industries. Notably, a case study in the aerospace sector highlighted the advantages of tungsten carbide molds in enhancing precision during high-temperature applications. The use of tungsten tooling allowed for tighter tolerances and longer tool life, significantly reducing downtime and maintenance costs. Aerospace manufacturers reported an increase in production efficiency, as the durability of tungsten tooling minimized the frequency of tool replacements.

In the automotive industry, a leading manufacturer adopted tungsten tooling for machining complex engine components. This transition not only improved the surface finish of the parts but also accelerated the production process. The heat resistance and wear resistance of tungsten tools enabled the manufacturer to achieve higher throughput while maintaining stringent quality standards. Feedback from the production team indicated a noticeable reduction in scrap rates, showcasing that tungsten tooling not only meets the demands of precision engineering but also contributes to cost-effectiveness in manufacturing workflows.

This chart illustrates the performance benefits of tungsten tooling in manufacturing processes compared to traditional tooling. The data demonstrates the increased tool life and reduced production costs associated with using tungsten tooling.

The future of tungsten tooling in advanced manufacturing technologies is poised for significant evolution, driven by ongoing innovations and the increasing demands for precision and durability. As manufacturers look to enhance their productivity and efficiency, tungsten’s superior properties make it an ideal candidate for the next generation of tooling solutions. The inherent hardness and thermal resistance of tungsten allow for higher cutting speeds and longer tool life, which are essential in the fast-paced landscape of modern fabrication. This shift is especially relevant in industries such as aerospace and automotive, where the need for high-performance materials is critical.

Emerging trends show a growing integration of tungsten tooling with cutting-edge technologies such as additive manufacturing and smart machining. With the rise of Industry 4.0, the implementation of Internet of Things (IoT) principles into manufacturing processes will allow for real-time data collection and analysis, optimizing the use of tungsten tools. Additionally, advancements in coating technologies and surface treatments will further enhance the performance and longevity of tungsten tooling, making it indispensable in precision engineering applications. As manufacturers adapt to these technological changes, the demand for innovative tungsten solutions is expected to increase, marking a transformative era in advanced manufacturing practices.