Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

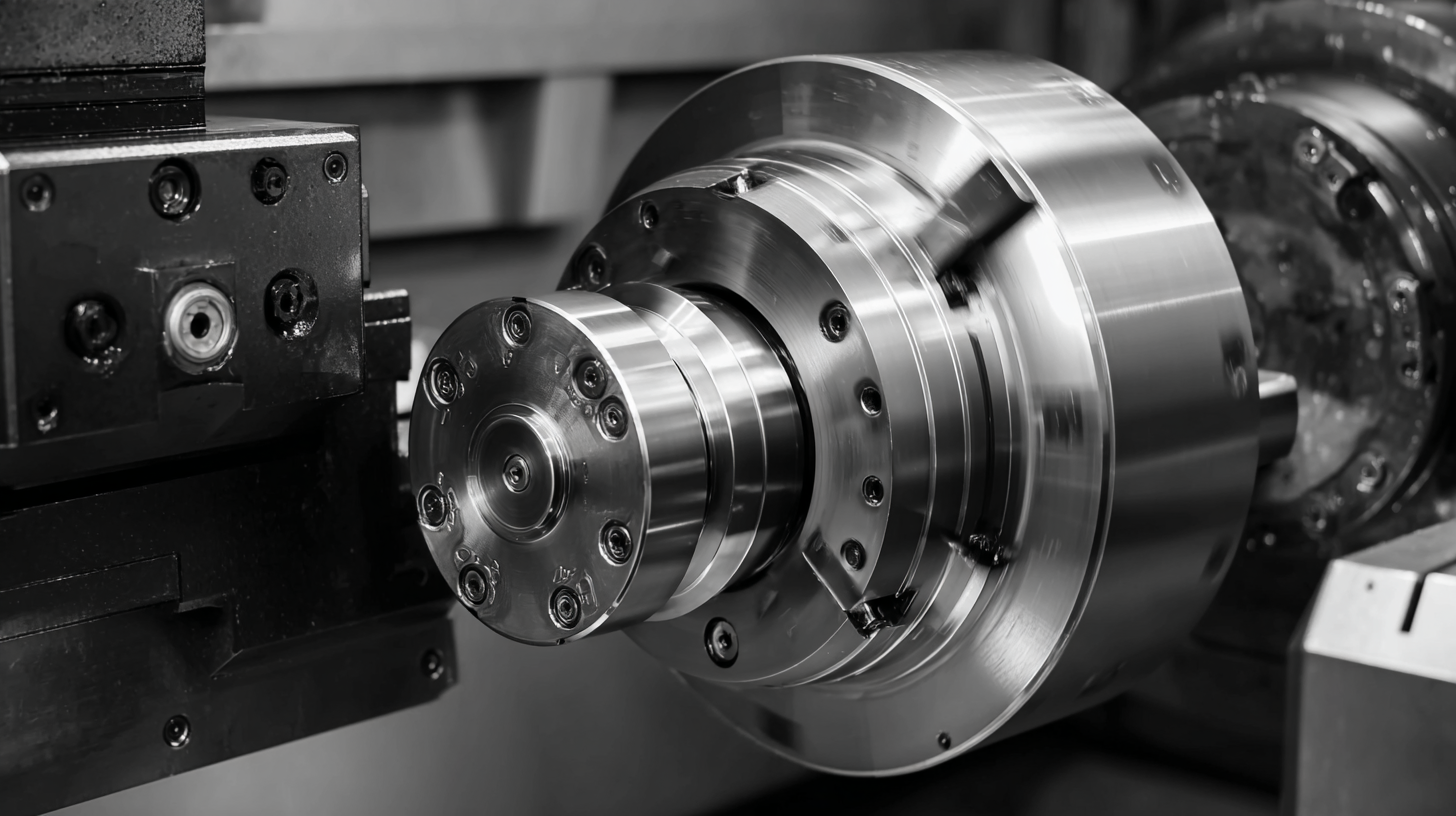

In the ever-evolving landscape of machining, the selection of the right lathe insert is paramount for optimizing efficiency and productivity. With the global machine tool market projected to reach $120 billion by 2025, according to a report by MarketsandMarkets, the significance of precision tooling becomes even more pronounced. Lathe inserts, with their critical role in shaping and finishing materials, directly impact tool life and machining speed. A study by Technavio estimates that advancements in insert technology will contribute to an annual growth rate of 5% in the lathe insert segment. Companies that leverage advanced lathe insert options not only enhance their operational capabilities but also solidify their positions as leaders in the competitive manufacturing landscape. Hence, mastering the nuances of lathe insert selection is essential for manufacturers aiming to maximize both output and efficiency in their machining processes.

Lathe inserts play a crucial role in machining performance, impacting everything from cutting forces to surface integrity. Recent studies highlight the significance of material selection for inserts, especially when dealing with difficult-to-cut materials. For instance, CNT-coated tools have demonstrated notable reductions in cutting tooltip temperatures and tool wear, outperforming both DLC and TiAlN coatings. This performance advantage is essential in high-speed turning, where optimized insert selection directly contributes to reduced operational costs and enhanced efficiency.

Moreover, the methodologies employed in machining, such as the Taguchi design and response surface methodology, provide significant insights into how cutting parameters affect both performance and quality. Techniques to model roughness parameters further inform the choice of inserts, ensuring that operators can predict and enhance machining outcomes. By leveraging these advanced tools and coatings, manufacturers can optimize their machining processes, thus ensuring improved surface integrity and economic viability in today's competitive landscape.

When it comes to achieving optimal machining efficiency, selecting the right lathe inserts is crucial. The variety of lathe inserts available in the market can be overwhelming, but understanding their specific applications can significantly enhance your machining processes. For instance, carbide inserts are widely favored for their durability and heat resistance, making them ideal for high-speed machining operations. These inserts excel when used with tougher materials, providing longevity and reducing downtime due to wear.

Another popular type is the ceramic insert, known for its remarkable hardness and thermal stability. While not suitable for all materials, these inserts shine in high-speed turning of non-ferrous metals, where they can effectively cut through tough surfaces and yield fine finishes. On the other hand, coated inserts offer a layer of protection that enhances performance under diverse conditions. By carefully considering the material to be machined and the specific requirements of each operation, machinists can select inserts that not only improve efficiency but also deliver exceptional quality in their finished products.

This chart illustrates the efficiency of different lathe insert types based on their applications in machining operations.

When it comes to selecting the right lathe insert for optimal machining efficiency, understanding the specific material you are working with is crucial. Several key factors influence the performance of cutting tools, such as the properties of the workpiece material, the cutting conditions, and the desired surface finish. For example, studies indicate that machining materials like AISI 4140 steel require careful management of heat generation and friction to maintain surface integrity. The choice of cutting speeds, feed rates, and depth of cut can significantly affect surface roughness and tangential cutting forces. In high-speed machining of Inconel 718, a well-optimized combination of these parameters can minimize adverse effects on the machined surface.

Moreover, color-coding schemes from insert manufacturers serve as a valuable guide for machinists, helping to quickly identify the appropriate tool for various applications based on material compatibility. This system enhances the decision-making process in selecting inserts for specific materials, improving efficiency and reducing the likelihood of tool failure. Continuous advancements in cutting tool materials, including cemented carbide inserts, also play a critical role in improving tool performance under rigorous conditions. Selecting the right insert not only influences productivity but also contributes to the overall cost-effectiveness of machining operations.

When selecting lathe inserts, understanding the comparative advantages of various materials and geometries is crucial for optimizing machining efficiency. Recent studies have highlighted the performance differences between single coated cermet and multilayer-coated carbide inserts. These tools exhibit distinct wear behaviors and cutting efficiencies, particularly when employed on challenging materials, such as Inconel 718 nickel-based super alloys. The geometry of chip breakers plays a pivotal role in determining the cutting force and the shape of the chips produced, impacting overall tool life and performance.

Moreover, a detailed investigation into chip breaker geometries has revealed significant implications for cutting efficiency. For instance, varying configurations can influence critical parameters such as bending moments and material removal rates (MRR). In experiments focusing on multi-radii geometries, findings suggest enhanced surface integrity and minimized tool wear during the turning processes.

Thus, manufacturers and machinists must carefully evaluate insert geometries in conjunction with the materials being machined to achieve better surface quality and reduced specific cutting energy. This nuanced approach enables a more efficient and sustainable manufacturing process, contributing to improved operational outcomes.

When it comes to enhancing machining efficiency, the selection of the right lathe insert is crucial. One of the best practices is to assess the material being machined and match it with an insert designed specifically for that material. For example, carbide inserts are well-suited for harder materials due to their high wear resistance, while ceramic inserts can cut faster in less demanding tasks. Additionally, understanding the insert’s geometry, such as rake angle and clearance, helps reduce cutting forces and improve surface finish, contributing to longer tool life.

Another important aspect is optimizing cutting parameters, such as feed rate and cutting speed. Using manufacturer's recommendations can provide a solid starting point, but fine-tuning these parameters based on real-time feedback from the machining process is essential. Monitoring tool wear can guide adjustments; for instance, if chatter occurs, it might be indicative of a need to lower the feed rate or select a different insert type. Implementing these best practices not only extends tool life but also boosts overall machining efficiency, leading to higher productivity and cost-effectiveness.