Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

In the fast-evolving landscape of industrial materials, Titan Carbide stands out for its unmatched durability and resistance to wear. A recent market analysis by Global Materials Insights indicates that the Titan Carbide applications are expected to grow by 30% annually through 2026. This surge is driven by its versatile usage in sectors such as mining, manufacturing, and construction.

Expert John Anderson, a prominent figure in the Titan Carbide industry, emphasizes, "The potential of Titan Carbide is immense when optimized for specific applications." His statement reflects the ongoing exploration of tailored solutions that can maximize the benefits of Titan Carbide. Companies are increasingly recognizing that effective implementation can significantly enhance performance and efficiency.

However, the journey is not without challenges. The education surrounding Titan Carbide remains limited for some engineers. Misunderstandings about its properties can lead to underutilization. A better grasp of its applications is critical for fully harnessing its benefits. This suggests a potential gap that industry professionals must address through targeted training and resources. The future of Titan Carbide is promising, but clarity and innovation are essential to unlock its full potential.

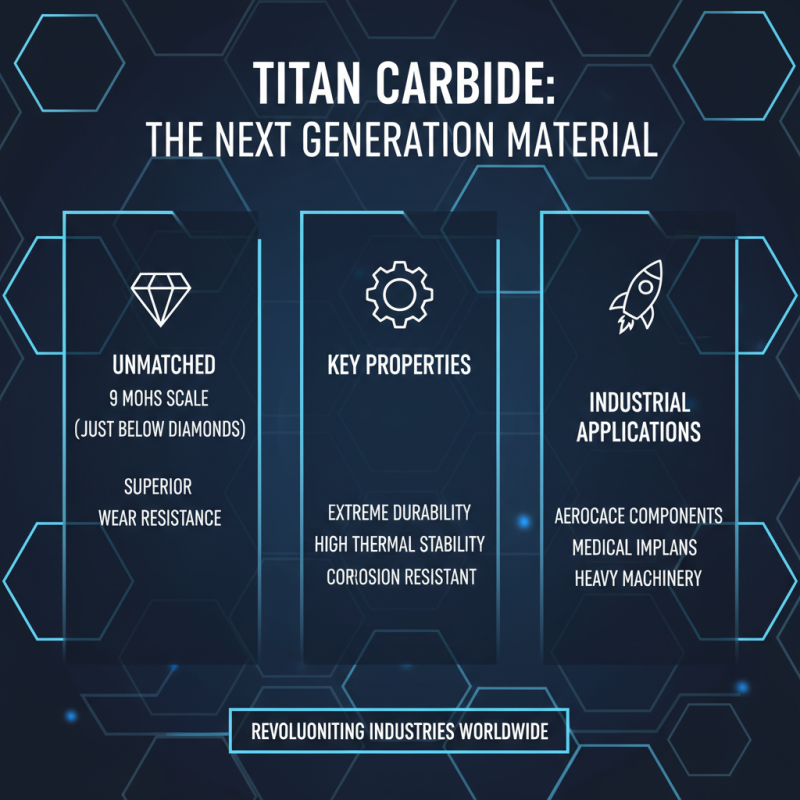

Titan carbide is gaining attention in various industries. Its unique properties set it apart from other materials. With a hardness rating just below diamonds, titan carbide offers exceptional wear resistance. According to a recent industry report, it boasts a hardness of 9 on the Mohs scale. This makes it ideal for applications where durability is crucial.

The material exhibits excellent thermal stability. It can withstand high temperatures without degrading. This quality is vital in manufacturing settings where heat can be an issue. Its resistance to oxidation further enhances its utility in extreme environments. However, sourcing the raw materials for titan carbide can be challenging and may cause fluctuations in supply.

Another significant advantage is its lightweight nature. Titan carbide maintains strength while being lighter than steel or tungsten carbide. This reduces the overall mass of equipment, improving efficiency. Nonetheless, the production process is complex and may not be sustainable in all regions. The balancing act between its benefits and resource constraints raises questions for future development.

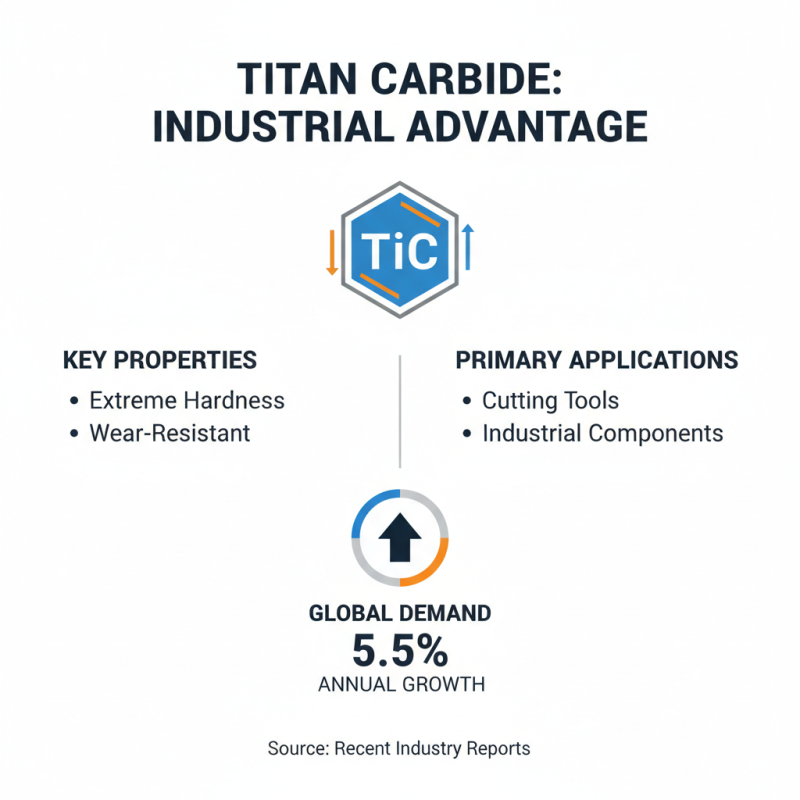

Titan carbide is gaining traction in various industrial sectors due to its unique properties. Its hardness makes it ideal for cutting tools and wear-resistant applications. According to recent industry reports, the global demand for titan carbide in manufacturing is projected to increase by 5.5% annually.

A notable application of titan carbide is in the mining sector. It is used in drill bits and rock tools, which are subjected to extreme stress. Studies show that using titan carbide can extend tool life by up to 30%. This leads to reduced downtime and cost savings for mining companies.

Tips: When selecting materials, consider the specific conditions they will face. Evaluate factors like temperature, pressure, and type of material being processed.

In the field of surface engineering, titan carbide coatings enhance abrasion resistance. These coatings are essential for maintaining machinery in high-friction environments. Research indicates that coatings can improve performance efficiency by nearly 20%. However, applying these coatings can be complex. Misalignment during the application process can lead to inadequate protection.

Tips: Ensure proper surface preparation before application. This can significantly impact the effectiveness of the coating. Regular assessments can help identify potential issues early.

Titan carbide offers significant advantages over traditional materials in various applications. Unlike conventional options, titan carbide shows superior hardness and wear resistance. This ensures longer tool life and less frequent replacements, which can lead to cost savings over time. The material's heat resistance further enhances its performance in extreme conditions, making it suitable for demanding industrial settings.

Moreover, titan carbide components often weigh less than their traditional counterparts. This reduction in weight can improve efficiency in machinery and reduce energy consumption. However, some may find the initial investment in titan carbide to be higher. It’s essential to weigh these costs against the long-term benefits. Are the upfront expenses justified by savings in maintenance and replacement? Scrutinizing these factors is vital for informed decision-making.

Titan carbide is gaining attention across various industries for its unique properties. This material offers impressive hardness and wear resistance, making it ideal for harsh environments. Its applications are expanding rapidly, driven by the need for durable solutions. Manufacturers are exploring new ways to integrate titan carbide into their processes. This shift reflects a growing awareness of its benefits, but challenges remain.

Future trends suggest a potential for titan carbide to be used in more advanced applications. Enhanced manufacturing techniques could lead to lighter, stronger components. Innovations in coating and surface treatment may further improve its performance. However, there are lingering questions about cost-effectiveness. As industries aim to adopt these materials, balancing performance with affordability will be crucial.

The exploration of titan carbide also reveals areas for reflection. Current research often overlooks environmental impacts. The extraction and production processes may not be sustainable. While titan carbide can improve product lifespan, its overall lifecycle must be considered. The journey of this material is just beginning, and ongoing evaluation will shape its future role.

When selecting Titan Carbide for specific applications, several factors come into play. First, think about the environment where the material will be used. Is it high-temperature or high-pressure? Titan Carbide shines in extreme conditions, but it can be overkill for milder settings.

Also, consider the desired durability and wear resistance. Titan Carbide offers superior hardness. However, it may not be the best choice for every application. Balance between performance and cost is crucial. Sometimes, a less expensive material can provide adequate durability without unnecessary expenses.

**Tips:** Always assess compatibility with other materials. Some combinations may lead to unexpected failures. Make a small-scale test before full implementation. This approach often uncovers potential issues early on.

It’s also wise to gather user feedback. Real-world experiences can highlight unforeseen challenges. Engage with industry peers to learn from their successes and failures. This insight can guide your choice effectively, allowing you to make informed adjustments as necessary.

| Application | Benefits | Considerations |

|---|---|---|

| Mining Tools | High wear resistance, increased tool life | Cost vs longevity balance |

| Agricultural Equipment | Enhanced durability, reduced maintenance | Compatibility with existing machinery |

| Construction Tools | Increased productivity, lower downtime | Application-specific design |

| Oil and Gas Industry | High temperature resistance, reliable performance | Material sourcing and processing conditions |

| Manufacturing | Precision machining, cost-effective | Machining parameters and tooling |