Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

In the dynamic landscape of modern manufacturing, the selection of appropriate tools is critical to achieving efficiency and precision. Cemented Carbide Tools have emerged as a cornerstone in this sector, largely due to their remarkable hardness and wear resistance properties. According to a report from Freedonia Group, the global market for cemented carbide tools is projected to reach $20 billion by 2024, reflecting their growing significance in production processes. As manufacturers continually seek ways to enhance productivity and reduce costs, Cemented Carbide Tools offer a compelling solution through their superior performance in cutting, drilling, and shaping materials.

By integrating these advanced tools into their operations, companies can ensure enhanced tool life, improved machining accuracy, and reduced downtime, thereby aligning with the demands of an increasingly competitive marketplace. This article aims to delve into the various advantages of Cemented Carbide Tools, providing a comprehensive guide for manufacturers looking to optimize their production capabilities.

The evolution of cemented carbide tools has significantly transformed manufacturing industries over the decades. Initially developed in the 1920s, cemented carbide offered remarkable hardness and wear resistance compared to traditional tools. Early applications were limited, primarily focusing on metal cutting for aerospace and automotive sectors. However, as manufacturing demands grew, so too did the technologies surrounding cemented carbide, leading to advancements in formulations and processing techniques that enhanced tool performance and versatility.

With continuous innovations, cemented carbide tools have become essential in various manufacturing processes, including machining, drilling, and milling. The introduction of coating technologies further improved their durability and efficiency, enabling them to withstand higher temperatures and pressures. Modern manufacturing increasingly relies on automation and precision, where cemented carbide tools excel, contributing to increased productivity and reduced downtime. This evolution reflects a broader trend towards the optimization of manufacturing processes, showcasing how cemented carbide tools remain at the forefront of industrial advancements.

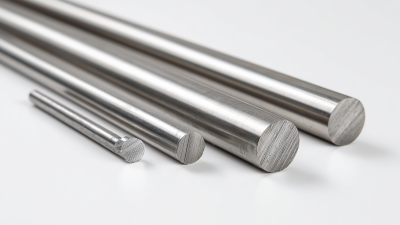

Cemented carbide tools are renowned for their exceptional hardness and wear resistance, making them invaluable in modern manufacturing processes. One of the key properties of cemented carbides is their high density, which contributes to their ability to withstand heavy cutting forces without deformation. This density not only enhances the tool's durability but also allows for improved precision in machining operations, leading to higher quality finished products.

Moreover, cemented carbides exhibit remarkable thermal conductivity. This property ensures effective heat dissipation during high-speed machining, reducing the risk of tool overheating and extending the tool's lifespan. The ability to maintain sharp cutting edges for extended periods is another advantage, allowing manufacturers to achieve greater efficiency and reduced downtime compared to tools made from other materials. Combined with their excellent chemical resistance, cemented carbide tools are ideal for cutting hard materials and can be utilized in a wide range of applications, demonstrating why they are a preferred choice in the manufacturing industry today.

Cemented carbide tools have gained significant traction in modern manufacturing, primarily due to their impressive

cost efficiency compared to traditional materials. Statistical analyses reveal that while the

initial investment for cemented carbide tools may be higher, the

long-term savings are substantial. These tools offer superior wear resistance

and longer tool life, which translates into less frequent replacements and reduced downtime during production.

In fact, studies indicate that manufacturers can save up to

30% on tooling costs over time when switching to cemented carbide.

Cemented carbide tools have gained significant traction in modern manufacturing, primarily due to their impressive

cost efficiency compared to traditional materials. Statistical analyses reveal that while the

initial investment for cemented carbide tools may be higher, the

long-term savings are substantial. These tools offer superior wear resistance

and longer tool life, which translates into less frequent replacements and reduced downtime during production.

In fact, studies indicate that manufacturers can save up to

30% on tooling costs over time when switching to cemented carbide.

Moreover, the productivity enhancements associated with cemented carbide tools cannot be overlooked. Their ability to

maintain sharpness and precision allows for faster machining speeds and improved surface finishes, which can lead to

higher quality products. This efficiency has been quantified in various industry

reports, showing that companies utilizing cemented carbide often experience a boost in overall production rates by up to

20%. Thus, the initial cost of investment in these advanced materials is quickly offset by the

financial benefits they deliver, positioning cemented carbide as a vital component in the drive for competitive advantage

in modern manufacturing contexts.

Cemented carbide tools are essential in precision engineering due to their unmatched durability and performance. These tools are primarily comprised of tungsten carbide particles bonded with a metal binder, which gives them superior hardness and wear resistance. As a result, they excel in machining high-strength materials and can withstand the extreme temperatures and pressures commonly encountered in manufacturing processes. In applications such as milling, turning, and drilling, cemented carbide tools enable manufacturers to achieve tighter tolerances and improved surface finishes, enhancing product quality.

Beyond their mechanical properties, the versatility of cemented carbide tools makes them invaluable in various industrial sectors, including aerospace, automotive, and medical device manufacturing. These tools are used for producing intricate components with complex geometries, allowing for innovations in design and functionality. Their ability to maintain cutting performance over prolonged use translates into increased productivity and reduced costs, making them a preferred choice in modern manufacturing environments focused on efficiency and precision.

The future of cemented carbide tool technology is poised for remarkable innovations that will enhance their performance in modern manufacturing. One notable trend is the development of advanced coatings that improve wear resistance and reduce friction. These coatings not only prolong tool life but also allow for higher cutting speeds and feeds, optimizing machining processes and increasing overall productivity. Additionally, the integration of nanotechnology in the manufacturing of cemented carbide tools is expected to lead to significant improvements in material properties, making tools tougher yet more lightweight.

Furthermore, the adoption of smart manufacturing technologies, such as Industry 4.0 principles, will revolutionize the use of cemented carbide tools. By incorporating sensors and data analytics, manufacturers can monitor tool performance in real time, enabling predictive maintenance and more efficient tool management. This not only enhances the lifespan of the tools but also maximizes operational efficiency. As industries continue to embrace sustainability, there is a growing focus on developing environmentally friendly manufacturing processes, which will also influence the evolution of cemented carbide tools, emphasizing recyclability and reduced environmental impact.

| Dimension | Traditional Tools | Cemented Carbide Tools | Future Trends |

|---|---|---|---|

| Durability | Moderate | High | Enhanced materials |

| Cutting Edge Retention | Short | Long | Improved geometry |

| Cost Efficiency | Lower initial cost | Higher initial cost | Lower lifetime cost |

| Applications | Basic machining | Precision and hard materials | Advanced manufacturing techniques |

| Environmental Impact | Variable | Lower waste | Sustainable practices |