Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

Choosing the right tungsten carbide can make a significant difference in your project’s success. This material is known for its exceptional hardness and durability. According to a report by Market Research Future, the global tungsten carbide market is expected to reach $20 billion by 2027. This growth emphasizes the increasing importance of tungsten carbide across various industries.

Dr. Jason Lee, a noted expert in materials science, states, "Selecting the proper tungsten carbide is crucial for optimizing performance in demanding applications." His insight highlights that there is no one-size-fits-all solution. Different grades of tungsten carbide serve different purposes. Factors such as grain size and binder content can dramatically alter performance characteristics. Ensuring the right specifications is key.

Understanding your specific needs can be overwhelming. However, investing time in research can prevent costly mistakes. The right tungsten carbide not only affects your budget but also impacts the longevity of the tools and machinery you invest in. Thus, careful evaluation is essential for ensuring that your selection meets both your operational and financial requirements.

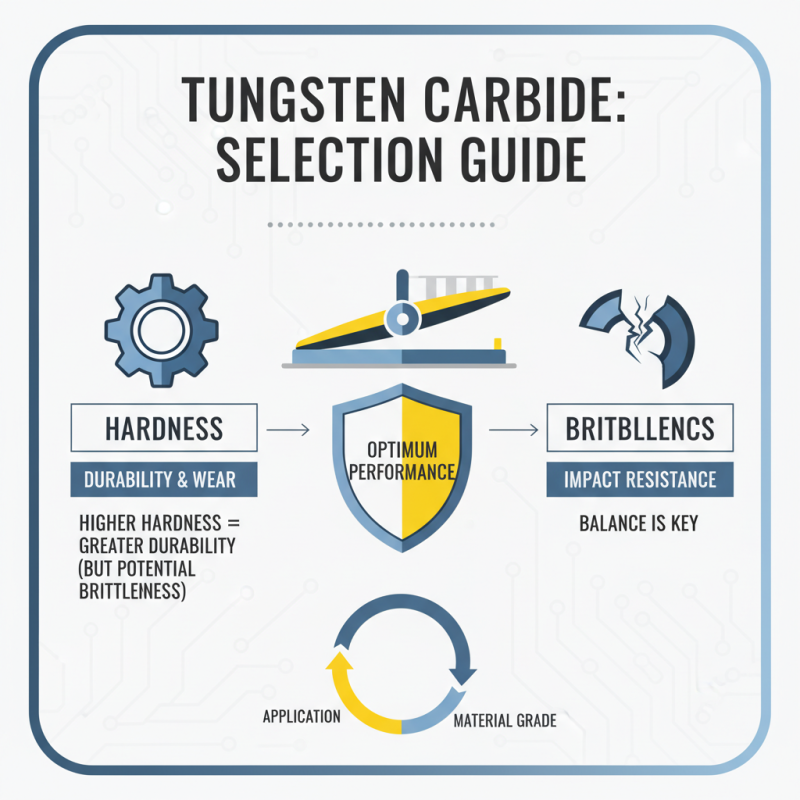

When selecting tungsten carbide, several factors must guide your decision. The hardness of tungsten carbide is crucial. It can vary significantly, affecting durability and wear resistance. A higher hardness often translates to better durability but might become brittle. Balance is vital here.

Consider the specific application. If you need tungsten carbide for machining, look for finer grain sizes. Finer grains enhance wear resistance but can be pricier. For jewelry or decorative items, aesthetic factors come into play. Surface finish and polish matter greatly in these cases. A beautiful finish can elevate an item’s appeal, drawing attention and interest.

Lastly, think about the cost against the expected performance. Sometimes, spending more leads to long-term savings through durability. However, not all high-cost options guarantee high-quality performance. Test different types if possible, as the right choice can feel subjective. Reflect on your needs and priorities. What works for one application may not suit another. Choosing the right tungsten carbide requires careful consideration of various factors and their implications.

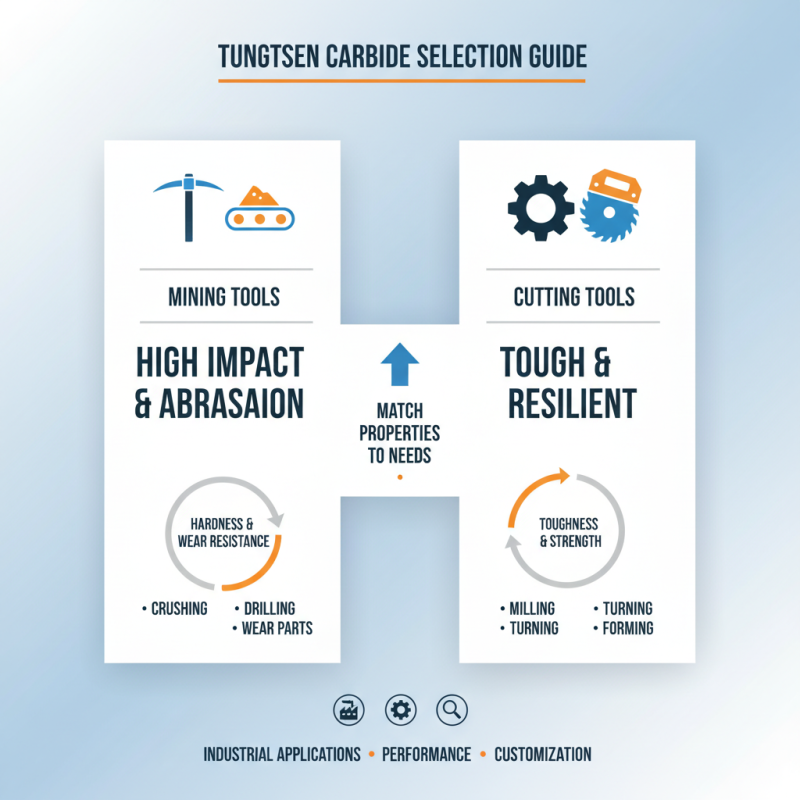

Tungsten carbide is a versatile material, known for its hardness and strength. It is widely used in industrial applications, including cutting tools and mining machinery. However, not all tungsten carbide is the same. Different grades can affect performance, longevity, and cost. Understanding these grades is crucial for making an informed choice.

There are two main classifications: cobalt-bonded and nickel-bonded tungsten carbide. Cobalt-bonded options can withstand higher temperatures. Yet, they might be susceptible to corrosion. On the other hand, nickel-bonded carbide provides better chemical resistance but often lacks in higher wear resistance. The choice depends on the working conditions. According to industry reports, nearly 65% of companies underestimate the impact of grade selection on tool life.

Additionally, the grain size of tungsten carbide plays a significant role in its performance. Finer grains typically enhance durability, while coarser grains may handle shock better. However, these finer materials can be more expensive and may seem like a luxury. Many businesses overlook this and choose coarser grades for cost reasons. They often face shorter tool life as a result. Understanding your specific requirements is key to avoiding costly mistakes.

When selecting tungsten carbide, consider your specific application requirements. Different industries have unique needs. For instance, mining tools require material that withstands high impact and abrasion. Conversely, cutting tools may require a tougher, more resilient form. Matching the properties of tungsten carbide to your needs is crucial.

**Tip:** Always check the hardness. High hardness provides better wear resistance. However, too much hardness can lead to brittleness. This balance is essential for performance.

Mechanical properties are not the only factor. The environment plays a key role. You might need corrosion resistance if the application involves chemicals or moisture. Applications in extreme temperatures will also change your selection process. It's important to reflect on whether your current choice suits all operational conditions.

**Tip:** Test different grades if possible. Observing real-world performance can highlight unexpected weaknesses. Learning from failures is a part of the process. Each application teaches something new.

When selecting tungsten carbide, finding the right cost-performance balance is essential. Tungsten carbide is durable yet varies significantly in price. A higher price often indicates superior quality and performance. However, not all applications require the best, most expensive options. Sometimes mid-range products can suffice, saving you money in the long run.

Performance needs should guide your choices. For heavy-duty applications, investing in premium-quality tungsten carbide might be necessary. In contrast, lighter tasks can get by with lower grades. Always consider the trade-offs. Cheaper options may wear out faster and require more replacements. Thus, time and effort could outweigh initial savings.

Market fluctuations can also affect costs. Prices change based on demand. Recent trends show fluctuating supply chains, leading to unpredictable pricing. It’s wise to track market conditions. Research provides insight into expected performance relative to costs. However, remember to weigh your specific needs against potential risks before making any investments.

This chart illustrates the cost and performance of different grades of tungsten carbide. The cost increases with the grade, while performance, measured in megapascals (MPa), also improves. This information can guide you in selecting the appropriate grade based on budget and performance requirements.

When considering tungsten carbide products, maintenance is crucial. Tungsten carbide is known for its strength, yet proper care extends its lifespan. Regular cleaning can prevent wear and tear, ensuring optimal performance. For example, using a soft cloth to remove dust keeps the surface intact.

Data from industry reports show that well-maintained tungsten carbide can last over a decade. However, neglect can shorten this lifespan significantly. A survey found that 25% of users faced issues due to improper maintenance. This highlights the importance of a consistent care routine.

Tips: Always store your tungsten carbide items in a dry place. Avoid exposure to harsh chemicals that can damage the material. Small steps make a big difference in durability. Consider checking your items periodically to catch wear early. A proactive approach can save time and cost in the long run.