Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

Choosing the right Tungsten Carbide Inserts can greatly impact your machining efficiency. As industry expert Dr. Emily Carter states, "Precision in selecting inserts is crucial for success." Understanding your specific needs is a challenge. Each option has unique properties that suit different applications, which can be overwhelming.

Tungsten Carbide Inserts are known for their durability and hardness. However, not all inserts are created equal. Factors like coating, geometry, and grade all play significant roles. You might find yourself confused when faced with numerous choices. That’s part of the journey—navigating through technical specifications can feel daunting.

Consider the material you're working with and the type of cut required. Trial and error often lead to improvement, even if it feels frustrating at times. Each selection process offers a learning experience. Mistakes can teach valuable lessons. In the end, thorough research will guide you in choosing the best Tungsten Carbide Inserts for your specific needs.

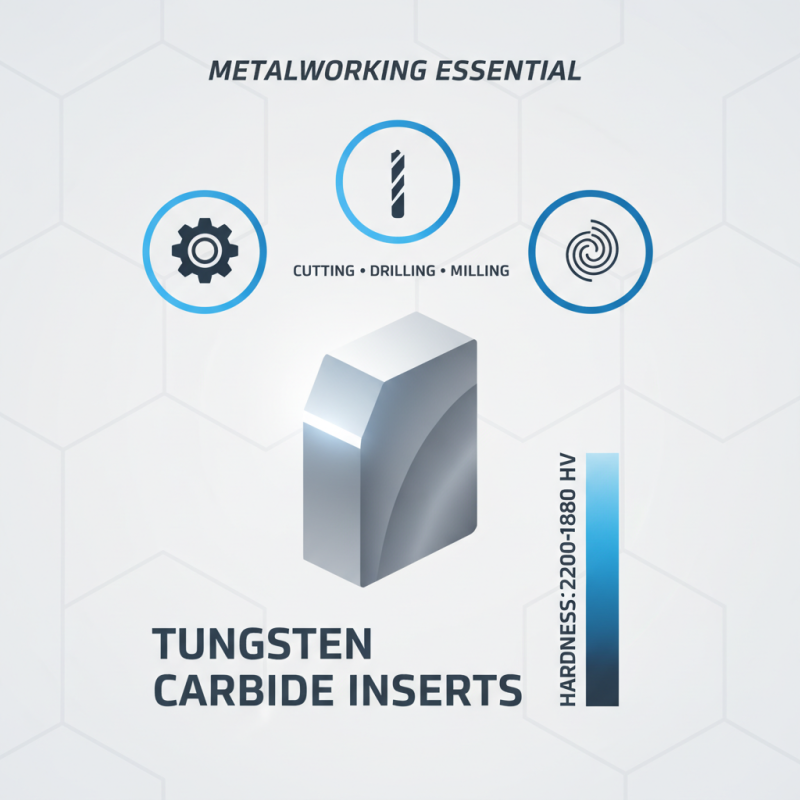

Tungsten carbide inserts are essential in metalworking. They are often used in cutting, drilling, and milling applications. Their hardness is a key feature, ranking between 1200 and 1800 HV on the Vickers hardness scale. This makes them suitable for high-performance tasks.

The application of tungsten carbide inserts varies widely. In industries like aerospace and automotive, they enhance productivity. A study from the International Journal of Advanced Manufacturing Technology indicates that these inserts improve tool life by 30% compared to standard materials. However, the performance of these inserts depends on the right choice for each specific task.

Choosing the correct insert is crucial. Factors like geometry and coating can impact effectiveness. A mismatch can lead to tool wear and reduced efficiency. According to recent industry reports, 20% of production losses stem from improper tooling choices. Understanding the specific requirements of your application will guide you in selecting the best tungsten carbide inserts.

When selecting tungsten carbide inserts, understanding their key properties is crucial. Tungsten carbide is known for its hardness and wear resistance. This material excels in high-temperature environments. Its ability to maintain sharp edges makes it a popular choice in manufacturing and machining tools.

However, not all tungsten carbide inserts are created equal. The grain size can significantly impact performance. Smaller grains generally enhance toughness, while larger grains can increase hardness. Users need to consider their specific operating conditions. Think about factors like cutting speed and material being machined.

Another important property is the cobalt content. Cobalt serves as a binder, affecting the durability of the insert. A higher cobalt percentage can lead to better impact resistance but may reduce hardness. Balancing these factors often requires testing and feedback. It's essential to reflect on past experiences with different inserts. Trial and error may guide you towards the best choice for your unique applications.

| Property | Description | Impact on Application |

|---|---|---|

| Hardness | Tungsten carbide has a high hardness rating, making it resistant to wear and abrasion. | Ideal for high-speed machining and cutting applications. |

| Toughness | Refers to the material's ability to withstand stress without fracturing. | Important for applications where impact and shock loading are factors. |

| Thermal Conductivity | Ability to conduct heat, affecting machining processes. | Influences tool life and performance during high-temperature operations. |

| Chemical Stability | Resistance to oxidation and corrosion at high temperatures. | Essential for applications in harsh environments or with reactive materials. |

| Grain Size | Refers to the particle size of tungsten carbide material. | Affects cutting edge sharpness and wear resistance; finer grains provide better performance. |

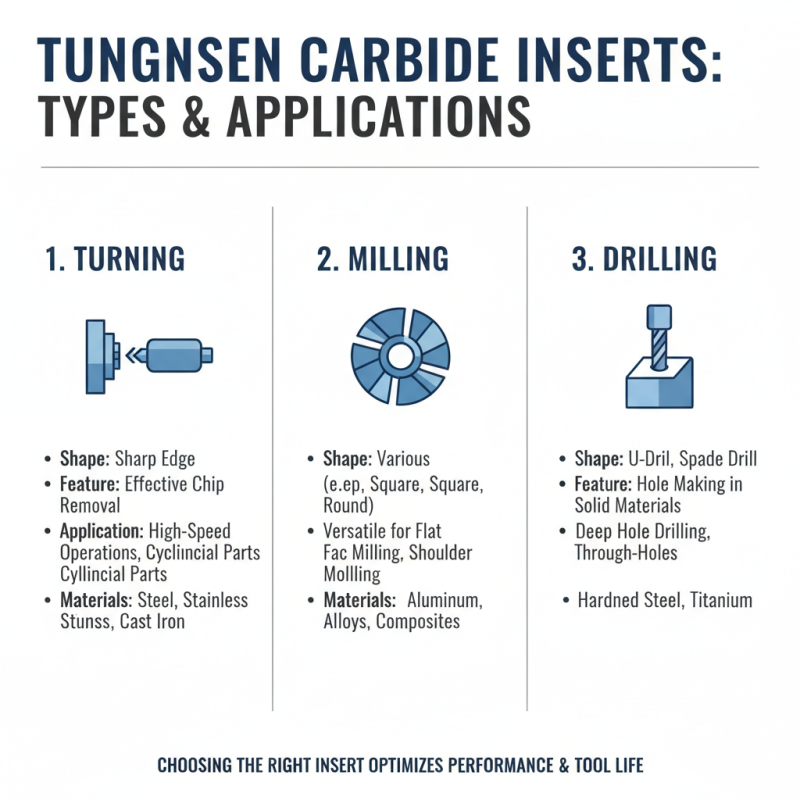

When choosing tungsten carbide inserts, understanding the types available is crucial. Tungsten carbide inserts mainly come in three categories: turning, milling, and drilling. Each type has specific applications suited to different materials and machining processes. For example, turning inserts often feature a sharp edge for effective chip removal. They're ideal for high-speed operations. On the other hand, milling inserts are designed for flat surfaces. They can be more versatile but may require more frequent replacement.

Data from recent industry reports indicate that the demand for tungsten carbide inserts is growing. In 2022, the global market was valued at approximately $7 billion, with projections to reach $10 billion by 2028. This growth underscores the importance of choosing the right insert type for your specific manufacturing needs. While many users select inserts based on popularity, this can lead to suboptimal performance.

Another common mistake is overlooking the material compatibility. Inserts designed for hardened steel may not perform well on aluminum. Each material behaves differently under machining conditions. Users should consider factors like workpiece material and type of cut. Failing to do so may result in excessive tool wear and increased costs. Understanding these details is vital.

Choosing the right tungsten carbide inserts starts with understanding your cutting conditions. Each material you work with requires specific tooling. For example, softer materials may need fewer cutting edges. Harder materials demand durability and wear resistance. Be attentive to the types of cuts you frequently make, as they can impact insert performance.

Tips: Always assess the cutting speed. It may vary based on material hardness. Too high speeds can lead to premature wear. Also, consider coolant use. It can enhance the lifespan of your inserts and improve cut quality.

Evaluating material compatibility is crucial. Not all inserts suit every application. Some designed for steel may not work well on aluminum. Look at the insert geometry; it greatly influences chip flow and clearance. Testing a few different types can often yield surprising results. Don’t hesitate to experiment. Keep a record of your findings; it helps refine future choices. Remember, trial and error is part of the process.

When selecting tungsten carbide inserts, cost-effectiveness and longevity are key factors. You want inserts that provide value over time. High initial costs can be tempting, but they may not always be worth it. Some cheaper options might wear out quickly. This can lead to frequent replacements, ultimately increasing your expenses.

It's essential to consider the material's resistance to wear and tear. High-quality tungsten carbide inserts often last longer, providing a better return on investment. Look for inserts that maintain their sharpness, even under heavy use. While more expensive, these options can save you time and effort in the long run.

Customer reviews can guide your choices, but they aren't infallible. Everyone's needs differ based on their specific applications. One user may have a great experience, while another may find the same product lacking. Experimenting with different inserts may yield better results for your unique requirements. Consider testing various options before committing.

This chart displays the cost-effectiveness and longevity indices of various tungsten carbide insert types. The Cost-Effectiveness Index rates the value relative to price, while the Longevity Index indicates the average operational hours each type can endure. This information is essential for selecting the best insert for specific operational needs.