Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

Choosing the right Lathe Insert is crucial for any machining operation. In the machining industry, 30% of tool wear occurs due to improper insert selection. This statistic highlights the importance of making informed choices. According to industry expert Dr. Mark Peters, “Selecting the right Lathe Insert can significantly enhance productivity and extend tool life.”

When you consider factors like material type and cutting speed, the decision becomes complex. Difficulties arise, especially when balancing cost with performance. For example, carbide inserts can handle tougher materials but are often more expensive. Understanding these trade-offs is essential for efficient machining practices.

Moreover, many manufacturers struggle to adapt their insert choices to evolving technology. It's not uncommon for businesses to overlook newer, more efficient inserts. Such mistakes can lead to increased costs and wasted materials. Reflecting on your insert choices can lead to greater effectiveness in your machining processes.

Lathe inserts play a crucial role in machining processes. They are the cutting tools that remove material from a workpiece. Selecting the right insert can dramatically affect machining efficiency and product quality. Each insert is designed for specific materials and operations, so understanding their characteristics is essential.

Consider the insert’s shape and coating. Different shapes optimize performance for contouring, facing, or threading. A variety of coatings enhance durability and reduce friction. However, not all inserts will perform well in every situation. An insert that excels in one material may fail in another. This inconsistency requires careful evaluation during the selection process.

Moreover, the choice of insert can influence tool wear and surface finish. Operators must anticipate the challenges of their specific project. Sometimes, it is necessary to experiment with multiple inserts to find the best fit. Balancing cost and performance is key. Reflection on past experiences can guide future decisions in insert selection. Adapting to these nuances is part of the machining journey.

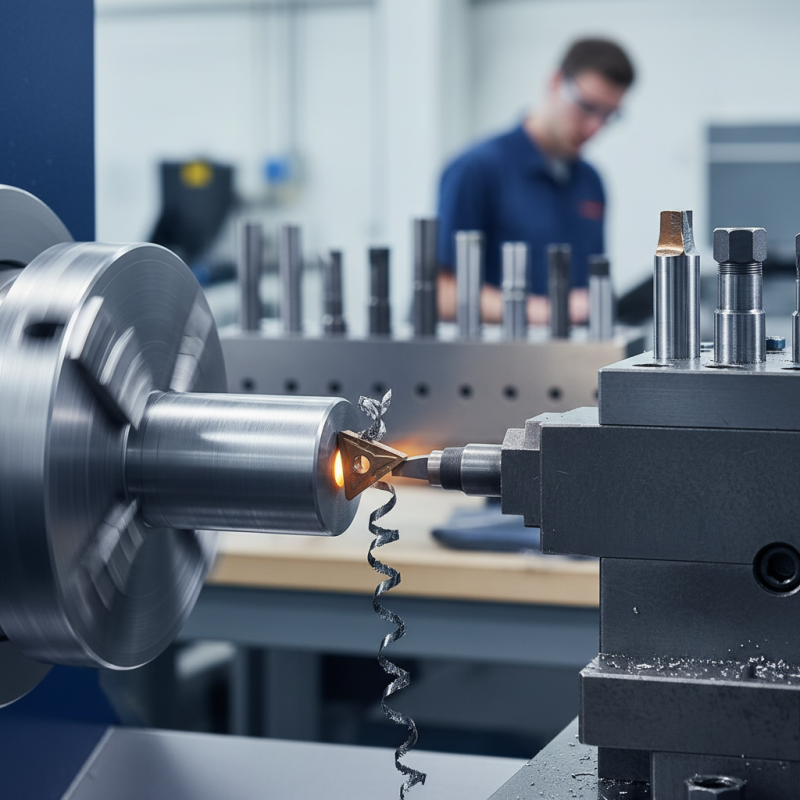

Lathe inserts are crucial for machining processes. They come in various types, each designed for specific tasks. For instance, high-speed tooling inserts are perfect for materials like aluminum. They facilitate faster cutting with less heat generation. On the other hand, carbide inserts are preferred for harder materials such as steel. They offer excellent wear resistance and longevity but might be more brittle.

Another type, ceramic inserts, can withstand high temperatures. They are suitable for steel and iron machining, especially in high-speed applications. However, tool life can be affected by cutting conditions. Adjusting speed and feed rates is essential. Not all materials behave the same.

Choosing the wrong insert can lead to poor performance. This can result in lower quality finishes or increased tool wear. It's vital to experiment and find the perfect fit. Sometimes, the ideal insert requires a learning curve. Matching your insert to the application is key—failure to do so can be costly.

Choosing the right lathe insert is crucial for efficiency in machining. Several key factors influence this decision. Material type is the first consideration. Different materials require specific insert compositions. For example, steel, aluminum, and plastic all behave differently. Matching the insert with the material enhances performance.

Another important factor is cutting conditions. Speed, feed rate, and depth of cut all affect insert wear. Understanding your machining environment can prevent premature failure. Inserts must withstand varying conditions, and that’s where careful selection comes in.

Tips: Always monitor wear patterns on your inserts. This helps in adjusting your choices for future projects. Keep experimenting with different inserts until you find the best fit. Test various combinations to see what works. It’s a learning curve every machinist must navigate.

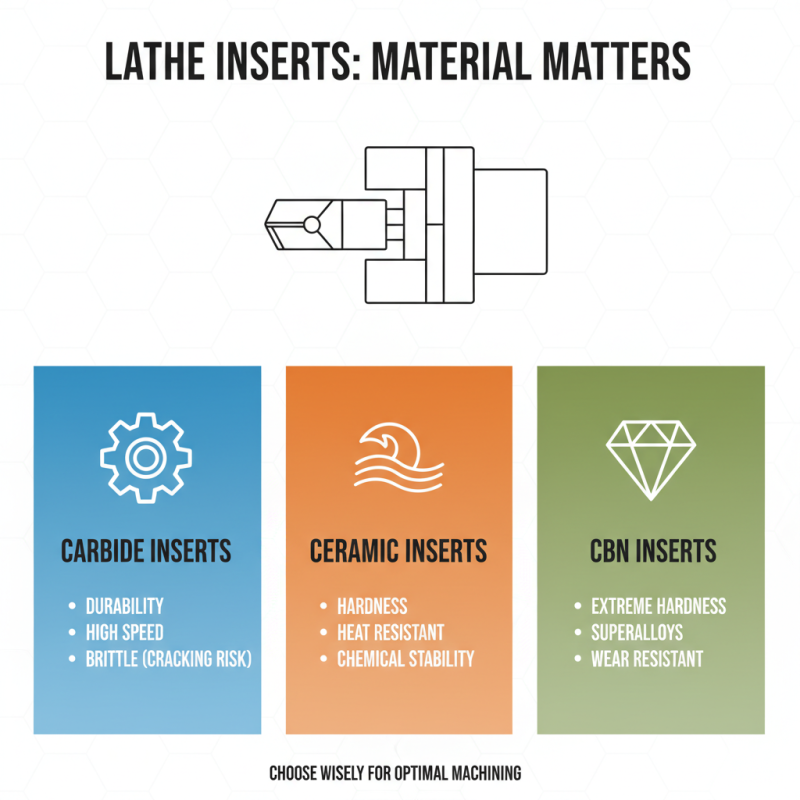

Choosing the right lathe insert can greatly influence your machining outcomes. The material of the insert plays a crucial role. Different materials exhibit unique properties. For instance, carbide inserts are known for their durability. They perform well at high speeds. However, they can be brittle. This brittleness sometimes leads to cracking.

Ceramic inserts offer excellent resistance to wear. They can handle high temperatures but are also fragile. These may not be suitable for every application. Some users find themselves facing premature failure. This can be costly and frustrating. A thorough understanding of material properties is necessary for successful machining.

High-speed steel inserts provide versatility. They are less prone to chipping but wear faster. Machinists must weigh performance against longevity. Finding the perfect balance can be tricky. Testing various inserts on actual projects may yield insights. There will be learning curves and swings of failure. Each material presents unique challenges and benefits. Proper selection is vital for achieving optimal results.

Choosing the right lathe insert can significantly impact machining performance. A cost-benefit analysis reveals that selecting appropriate inserts improves production efficiency. According to industry reports, proper insert choice can reduce tool wear by 30% and enhance surface finish quality. This means lower downtime and less rework, ultimately saving money.

In terms of upfront costs, high-quality inserts might seem pricey. However, the long-term savings are substantial. A study showed that companies using optimized lathe inserts saw a 15% increase in overall productivity. This is not an insignificant metric. While some may argue that cheaper inserts suffice, they often lead to increased tool changes and maintenance.

Delving deeper, it’s essential to consider material compatibility. Certain inserts perform better with specific materials, leading to varying results. Many machinists overlook this, resulting in subpar outcomes. Evaluating cutting speeds and feed rates is equally vital. If insert selection does not match the application, efficiency drops significantly.