Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

When it comes to selecting tools for precision work, the choice of material can significantly affect performance and durability. Among the various options available, Tungsten Tipped tools have gained popularity due to their exceptional hardness and resilience. These tools are designed to withstand extreme conditions, making them ideal for various applications, from metalworking to woodworking. However, with a wide array of Tungsten Tipped tools on the market, determining the best one for your specific needs can be a daunting task.

In this guide, we will explore the essential factors to consider when choosing a Tungsten Tipped tool. Understanding the nature of your projects, the intricacies of the materials involved, and the versatility of different Tungsten Tipped designs will help you make an informed decision. By highlighting key features such as tip geometry, coating technologies, and compatibility with existing tools, you will be equipped to select a solution that not only enhances your efficiency but also ensures long-lasting performance. Dive into the world of Tungsten Tipped tools and discover how they can elevate your craftsmanship to new heights.

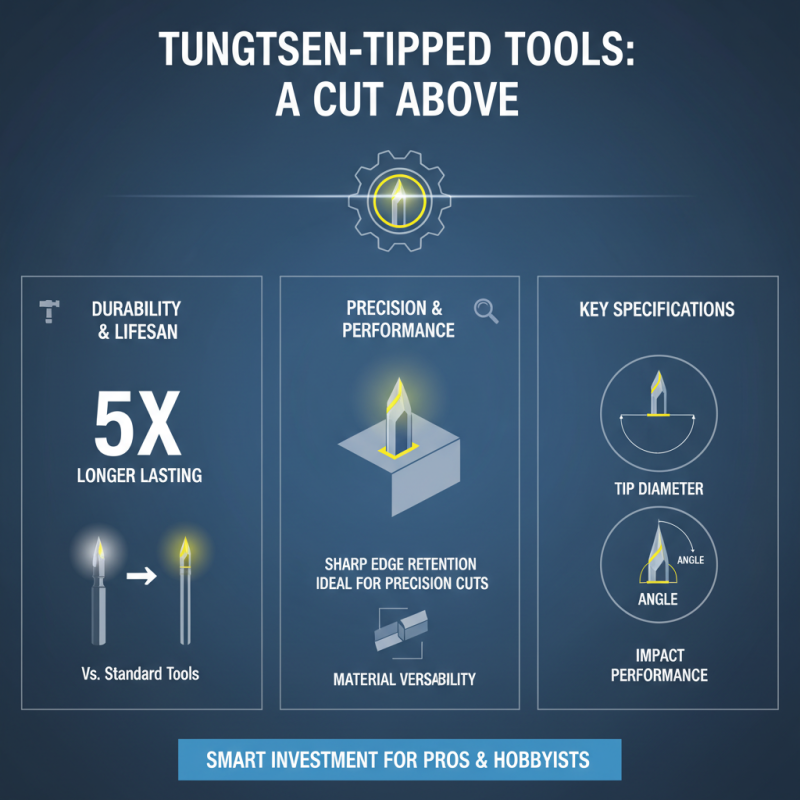

Tungsten tipped tools have gained popularity in various industries due to their unique properties that enhance performance and longevity. Tungsten is known for its exceptional hardness and resistance to wear, making it an ideal material for cutting tools, inserts, and drill bits. According to a report by the International Tooling Association, tools made with tungsten tips can last up to five times longer than their high-speed steel counterparts, resulting in significant cost savings for manufacturers and contractors alike.

Beyond durability, tungsten tipped tools offer superior precision and efficiency in machining applications. The high density of tungsten allows for better cutting performance, which translates to smoother surfaces and reduced friction. A study published in the Journal of Manufacturing Science revealed that using tungsten tipped tools can improve the machining speed by as much as 30%, thereby increasing productivity in manufacturing processes. The benefits extend to reduced tooling downtime and less frequent replacements, further enhancing operational efficiency.

Understanding these advantages is crucial for professionals looking to optimize their tool selection for specific applications. By considering factors such as material compatibility and the types of tasks being performed, users can choose the best tungsten tipped tools to meet their specific needs and achieve optimal results in their projects.

| Tool Type | Length (inches) | Tip Diameter (mm) | Material | Benefit |

|---|---|---|---|---|

| Tungsten Tipped Drill Bit | 6 | 10 | High-Speed Steel | Enhanced Durability |

| Tungsten Tipped Chisel | 8 | 12 | Carbon Steel | Precision Cutting |

| Tungsten Tipped Router Bit | 4 | 8 | Cemented Carbide | Smooth Finish |

| Tungsten Tipped Hole Saw | 5 | 20 | M42 Steel | Versatile Cutting |

When selecting the right tungsten tipped tool for your needs, there are several key considerations to keep in mind. First, consider the specific applications you will be engaging in. Tungsten tipped tools are renowned for their durability and cutting efficiency; however, different tools are designed for varying tasks. Whether you need a tool for metalworking, woodworking, or masonry, identifying your primary use will guide you to the most suitable option.

Another crucial factor is the tool's design and ergonomics. Comfort during use can significantly enhance your productivity and reduce the risk of injury. Look for tools that offer a good grip and are balanced, allowing for precise control. Additionally, check if the tool has replaceable tips. This can save you money in the long run and ensure that your tool remains efficient over time.

Tips: Always assess the hardness of the base materials involved in your projects. A tool with a tungsten tip typically offers better performance on harder materials. Don't shy away from seeking user reviews or expert opinions to gauge the effectiveness of specific tools. Lastly, consider your budget; while high-quality tungsten tipped tools can be an investment, they can also provide notable longevity and performance that outweigh initial costs.

When selecting the best tungsten tipped tools for specific applications, evaluating tool specifications is paramount. Tungsten tips are known for their durability and ability to maintain a sharp edge, making them ideal for precision cutting. According to a recent industry report, tools with tungsten tips can last up to five times longer than their standard counterparts, making them a practical investment for both amateur and professional users. It is essential to consider the diameter and angle of the tip, as these factors can significantly influence the tool's performance in various materials.

Tips: Always assess the intended application before making a purchase. For instance, a finer tip may be suitable for detailed woodworking projects, while a broader tip may excel in heavy-duty metalworking tasks. Additionally, reviewing user feedback and performance metrics can further guide your choice, ensuring compatibility with your specific requirements.

Furthermore, look into the hardness levels of the tungsten used in the tools. The Mohs scale of mineral hardness shows that tungsten ranks around 7.5, making it a robust choice for tools that encounter high abrasion. Choosing tools with a higher tungsten content can lead to enhanced performance and reduced wear over time. Ultimately, understanding these specifications enables users to select the most suitable tungsten tipped tool for their individual needs, enhancing productivity and achieving superior results.

When selecting the right tungsten tipped tool for your needs, comparing various brands and models is crucial. Each brand often has its unique design features and manufacturing processes that can affect performance and durability. Some brands may prioritize precision in cutting, making their tools suitable for intricate work, while others may focus on durability, ideal for heavy-duty tasks. It's essential to evaluate what level of wear and tear you anticipate in your projects to choose a brand that aligns with those expectations.

Furthermore, consider the specific models within these brands. Variations in tip shape and size can significantly impact the tool's effectiveness in different applications. For instance, some models may be better tailored for woodworking tasks, while others excel in metal fabrication. Thoroughly reviewing user feedback and expert recommendations on these models can provide insights into their real-world performance. Taking the time to research and compare features like weight, balance, and price will ensure that you make an informed decision that best suits your individual needs and enhances your productivity.

To ensure the longevity and efficiency of tungsten tipped tools, proper maintenance should be a top priority. Regular cleaning is essential, as it prevents debris from accumulating on the tips and clogs. After each use, wipe down the tools with a soft cloth to remove any metal shavings, dust, or residue. For more thorough cleaning, consider using a mild solvent suitable for the tool material to help dissolve any stubborn deposits.

Another crucial aspect of maintaining tungsten tipped tools is proper storage. Store your tools in a dry, cool place, away from direct sunlight and moisture. Using a protective case or sheath can also prevent accidental damage and keep the tips sharp. Additionally, avoid storing them loose in a toolbox, as this may lead to unwanted contact with other tools that could dull or chip the tungsten tips.

Finally, regularly inspect your tools for signs of wear or damage. If you notice any chipping or dullness in the tungsten tips, address these issues promptly to maintain performance. Resharpening or replacing the tips when necessary will ensure that your tools remain effective and safe to use. By following these maintenance tips, you can significantly prolong the lifespan of your tungsten tipped tools and enhance their overall performance.