Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

In today's highly competitive industrial landscape, selecting the right manufacturer for tungsten carbide products is crucial for optimizing performance and ensuring longevity. As reported by various industry studies, the global tungsten carbide market is projected to reach approximately $8.39 billion by 2026, growing at a CAGR of 5.4% from 2021. This growth is driven by the increasing demand for durable materials across sectors such as mining, construction, and manufacturing. Understanding the detailed technical parameters involved in tungsten carbide production—such as hardness, wear resistance, and thermal stability—can significantly influence manufacturing efficiency and product quality. This blog will explore essential factors to consider when choosing a manufacturer, focusing on industry insights and practical guidance to help stakeholders make informed decisions in sourcing premium tungsten carbide products for specific applications.

In today's highly competitive industrial landscape, selecting the right manufacturer for tungsten carbide products is crucial for optimizing performance and ensuring longevity. As reported by various industry studies, the global tungsten carbide market is projected to reach approximately $8.39 billion by 2026, growing at a CAGR of 5.4% from 2021. This growth is driven by the increasing demand for durable materials across sectors such as mining, construction, and manufacturing. Understanding the detailed technical parameters involved in tungsten carbide production—such as hardness, wear resistance, and thermal stability—can significantly influence manufacturing efficiency and product quality. This blog will explore essential factors to consider when choosing a manufacturer, focusing on industry insights and practical guidance to help stakeholders make informed decisions in sourcing premium tungsten carbide products for specific applications.

Tungsten carbide is a remarkable material known for its exceptional hardness and durability, making it an ideal choice for various industrial applications. Composed of tungsten and carbon, this composite material is not only resistant to wear but also maintains its strength at high temperatures. These properties make tungsten carbide a preferred option in industries such as mining, manufacturing, and aerospace, where it is used to create cutting tools, drill bits, and wear-resistant surfaces.

In addition to its mechanical properties, tungsten carbide's versatility extends to its use in jewelry and decorative items. Its luster and scratch resistance make it an appealing choice for rings and other accessories. As industries continue to innovate, understanding the myriad applications of tungsten carbide highlights its significance in enhancing productivity and efficiency across sectors. Manufacturers focusing on tungsten carbide products must prioritize quality and performance, ensuring that their offerings meet the rigorous demands of various industries.

| Property | Value | Application | Industry |

|---|---|---|---|

| Hardness | 8.5 - 9 on Mohs Scale | Cutting Tools | Manufacturing |

| Density | 14.5 g/cm³ | Wear Parts | Mining |

| Melting Point | 2870 °C | Piston Pins | Aerospace |

| Tensile Strength | 2000 MPa | Drill Bits | Construction |

| Thermal Conductivity | 90 W/m·K | Industrial Tools | Automotive |

Selecting the right manufacturer for tungsten carbide products requires careful consideration of several key factors, particularly the growing demand within specialized markets. The global dental diamond burs market is a prime example, valued at USD 130 million in 2021, with forecasts projecting a rise to USD 191 million by 2026 at an impressive CAGR of 8.0%. This robust growth highlights the necessity for manufacturers to deliver high-quality tungsten carbide tools that meet the rigorous standards of the dental industry.

Another critical aspect to consider is the durability and performance of tungsten carbide materials in agricultural applications. As farmers face pressure to increase yields while keeping costs low, the choice of materials in tillage tools becomes vital. Tungsten carbide components play a crucial role in enhancing the longevity and effectiveness of tillage equipment, ultimately contributing to better agricultural productivity. Moreover, advancements in coating technologies such as tungsten carbide coatings offer promising alternatives to traditional hard chrome plating, particularly in sectors like aerospace, thereby expanding the applicability and reliability of tungsten carbide products across various industries.

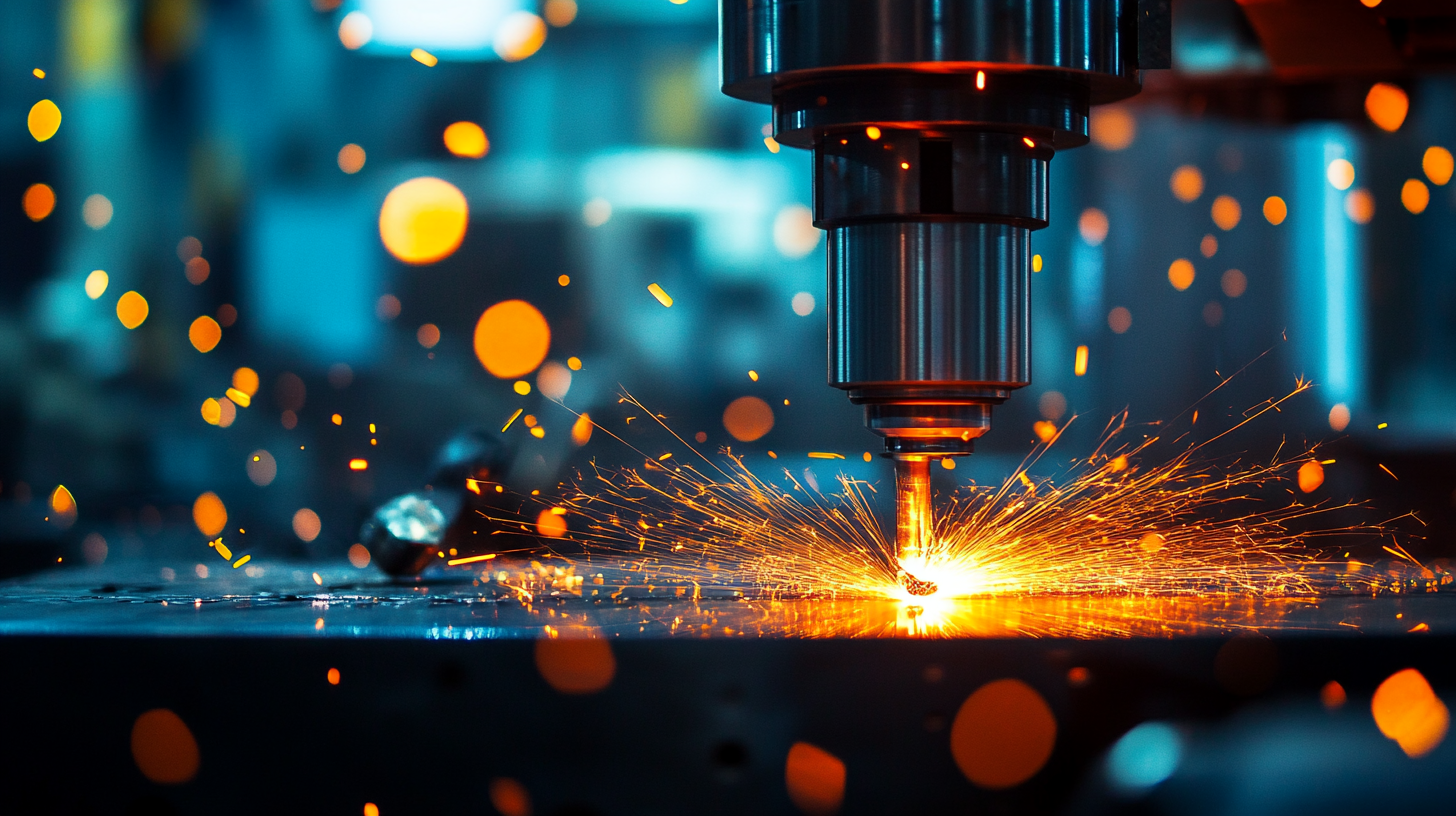

When exploring various types of tungsten carbide products, it’s essential to understand their specific applications and advantages in different industries. Tungsten carbide's hard, durable nature makes it a popular choice for manufacturing cutting tools, wear-resistant parts, and various industrial fixtures. However, with advancements in technology, particularly in 3D printing, the possibilities for tungsten carbide applications are expanding. By integrating fiber-reinforced composites, manufacturers can enhance the performance characteristics of tungsten carbide products, optimizing them for sectors such as aerospace, automotive, and medical fields.

In the context of evolving manufacturing techniques, comparing alternatives becomes crucial. Traditional methods of tungsten carbide production may not always meet the precision and customization demands of modern applications. Innovations in 3D printing allow for rapid prototyping and the creation of bespoke products that adhere to strict industry specifications. As industries continue to experiment with these cutting-edge manufacturing processes, exploring how tungsten carbide can be adapted through 3D printing will provide valuable insights into future product development and operational efficiency.

When it comes to purchasing tungsten carbide products, striking the right balance between quality and cost is crucial. As industries increasingly rely on durable materials, understanding the nuances of tungsten carbide becomes essential for making informed purchasing decisions. Quality is often reflected in the manufacturing process, where attention to detail and stringent quality control play significant roles. This leads to products that not only meet performance standards but also provide long-term reliability.

On the other hand, cost is a determining factor for many businesses. While it's tempting to opt for the lowest-priced products, this often correlates with inferior quality, which can ultimately lead to higher long-term expenses due to frequent replacements or repairs. Investing in reputable manufacturers who deliver high-quality tungsten carbide products may involve a higher initial outlay, but the long-term benefits and cost savings typically outweigh the upfront savings offered by lesser-quality alternatives. By carefully weighing these factors, businesses can make strategic choices that enhance overall productivity and minimize operational disruptions.

When it comes to selecting the right tungsten carbide solutions, understanding industry-specific needs is crucial for optimizing performance. Each industry, whether it be mining, manufacturing, or construction, has unique challenges that require tailored approaches. For example, mining applications demand materials that can withstand extreme conditions and abrasive wear. In such cases, manufacturers that specialize in high-density tungsten carbide formulations can provide products that not only enhance durability but also improve operational efficiency.

When it comes to selecting the right tungsten carbide solutions, understanding industry-specific needs is crucial for optimizing performance. Each industry, whether it be mining, manufacturing, or construction, has unique challenges that require tailored approaches. For example, mining applications demand materials that can withstand extreme conditions and abrasive wear. In such cases, manufacturers that specialize in high-density tungsten carbide formulations can provide products that not only enhance durability but also improve operational efficiency.

In the manufacturing sector, the focus shifts to precision and compliance with stringent safety standards. Here, incorporating advanced processing techniques and rigorous quality control measures ensures that tungsten carbide products meet the high expectations of precision engineering. By collaborating closely with manufacturers who understand these nuances, industries can achieve optimal performance, leading to reduced downtime and increased productivity. Tailoring solutions to meet specific challenges is not just beneficial; it is essential for maintaining a competitive edge in today's fast-paced market.