Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

Choosing the right Tungsten Metal Rod is crucial for various applications. These rods are known for their unique properties, such as high density and melting point. They are often used in industries like aerospace and electronics.

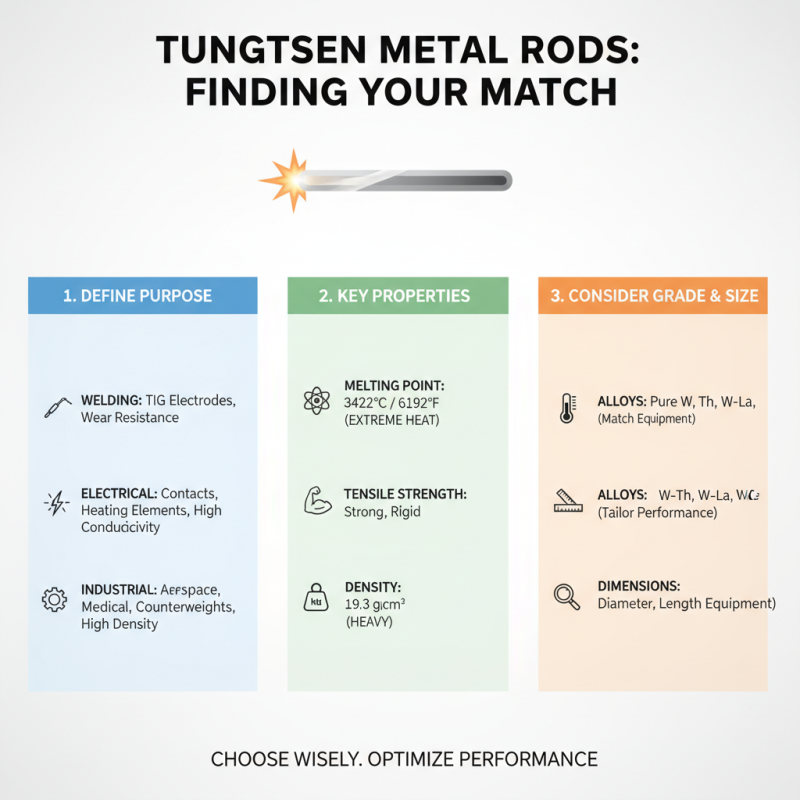

Understanding your specific needs is the first step. For instance, are you welding, machining, or using these rods for another purpose? There isn't a one-size-fits-all solution. You might need a certain diameter or length. Often, people overlook these details, leading to poor performance.

Quality matters too. Not all Tungsten Metal Rods are created equal. There are different grades available. Some may not withstand high temperatures as others do. Reflecting on your project requirements can help make a better choice. Remember, a small mistake can affect the entire outcome.

Tungsten metal rods possess unique properties that make them valuable in various applications. With a density of 19.3 g/cm³, tungsten is one of the heaviest metals. This characteristic contributes to its effectiveness in tasks requiring stability and weight. The melting point of tungsten is around 3,422°C, making it ideal for high-temperature applications. Industries use tungsten rods in aerospace, military, and manufacturing.

The hardness of tungsten, rated at 8.5 on the Mohs scale, ensures durability in harsh environments. However, working with tungsten has its challenges. Cutting and shaping the metal require specialized tools. The rigidity can lead to difficulties in fabrication. Some reports indicate that improper handling can increase production costs by 20%. Understanding these properties helps in making informed choices.

Applications of tungsten rods range from electrical contacts to radiation shielding. Their use in welding processes is crucial for ensuring strong joints. In medical devices, tungsten rods are pivotal for their non-reactive nature. Despite their advantages, users must consider the appropriate size and length for specific tasks. A mismatched rod can lead to inefficiencies and increased repair needs. Recognizing these details is essential for successful applications.

| Property | Description | Common Applications |

|---|---|---|

| Density | Tungsten has a density of approximately 19.25 g/cm³, making it one of the heaviest metals. | Aerospace components, military applications, and radiation shielding. |

| Melting Point | The melting point of tungsten is around 3422°C (6192°F), the highest of all metals. | High-temperature applications, such as rocket engines and incandescent light bulbs. |

| Thermal Conductivity | Good thermal conductivity compared to other metals, facilitating efficient heat transfer. | Heating elements in industries and electronics. |

| Corrosion Resistance | Highly resistant to corrosion, especially in acidic environments. | Chemical processing industries and military applications. |

| Strength | Exceptional tensile strength and hardness, making it suitable for heavy-duty applications. | Manufacturing of cutting tools, dies, and wear-resistant components. |

Choosing the right tungsten metal rod involves understanding your specific needs. Each application requires a unique set of properties, from tensile strength to melting point. Think about the purpose of the rod. Is it for welding, electrical applications, or something else? Defining this can help narrow options.

For welding, consider diameter and length. A thicker rod generally offers more strength. If precision is key, a thinner rod might suit your needs better. Reflect on how you will work with the rod. Will you be using it in tight spaces? If so, size matters significantly.

Tips:

1. Evaluate the environment where the rod will be used. High temperatures can affect performance.

2. Take note of the rod’s density. Heavier rods can provide better stability in dynamic applications.

3. Consult with experts or colleagues. Their experience can provide valuable insights.

Assess your requirements carefully. Each choice impacts your project’s outcome. Consider these factors before making a decision.

When choosing a tungsten metal rod, evaluating its grade and specifications is crucial. Different grades, such as 1.0% and 2.5% tungsten, offer unique properties. For instance, 2.5% tungsten enhances overall strength and is commonly used in high-temperature applications. According to industry data, the tensile strength of tungsten can reach up to 1510 MPa for certain grades, making it ideal for demanding environments.

Specifications are also essential. The diameter and length of the rod can affect its usability in various applications. A 1/4 inch diameter may be suitable for intricate welding tasks, while larger diameters are preferred for heavy-duty applications. Pay attention to the purity level as well. Tungsten with higher purity generally delivers better performance and durability. Research indicates that a purity level of 99.95% can significantly improve thermal conductivity.

There's a learning curve when selecting the right rod. Not all applications require the highest grade. Sometimes, a lower-grade rod may suffice, leading to cost savings without compromising performance. Users must evaluate their specific needs thoroughly, as the wrong choice can lead to inefficiency. Exploring these options carefully can prevent frustration down the line.

Choosing the right tungsten metal rod involves understanding dimensions and tolerances. Accurate dimensions are critical for various applications. Whether it’s for aerospace or medical devices, precision matters. Typical tungsten rods come in diameters ranging from 1mm to 50mm. Lengths can vary widely, often from 50mm to 1 meter. These specifications directly affect performance.

Tolerances in tungsten rods can impact functionality. Standard tolerances might be around ±0.05mm, but tighter tolerances are often required in high-stakes environments. According to industry reports, some sectors demand tolerances as precise as ±0.01mm. This level of precision ensures compatibility and reliability in critical applications.

Understanding these specifications is not always straightforward. Misjudging the importance of diameter or tolerance can lead to failures. A dimensional miscalculation of just a few millimeters might render a rod unusable. Many engineers find it challenging to strike the right balance between cost and precision. It’s important to reflect on these choices deeply. The right rod is not just about meeting basic requirements; it's about ensuring durable, reliable performance in demanding conditions.

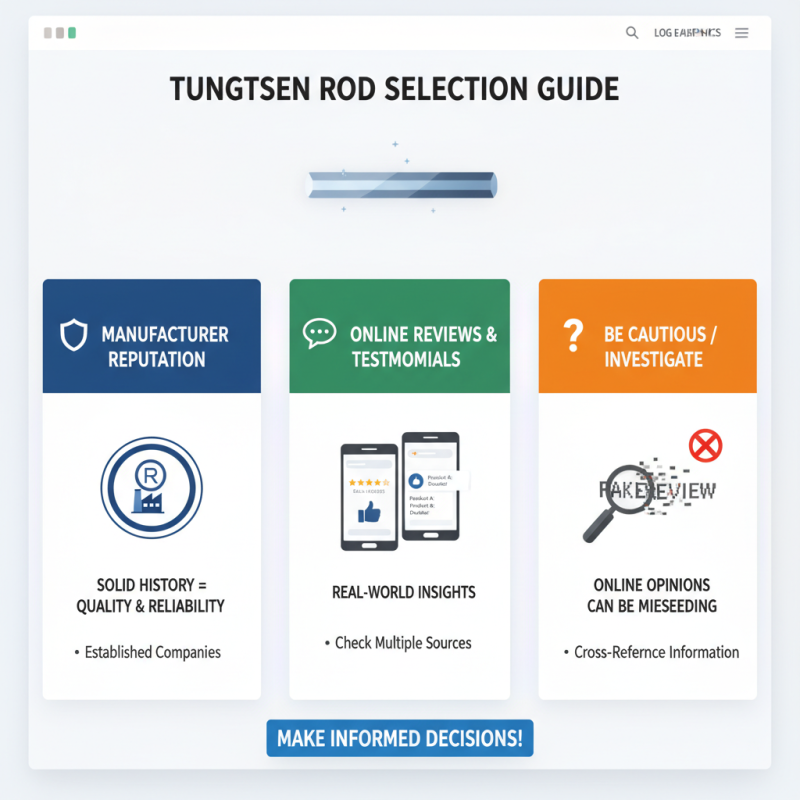

When selecting a tungsten metal rod, manufacturer reputation plays a crucial role. A company with a solid history often signals quality and reliability. Look for online reviews and testimonials. They provide real-world insights into their products. However, be cautious; online opinions can be misleading. Investigate through multiple sources.

Quality assurance practices are vital indicators of a manufacturer's commitment. Some manufacturers may boast exceptional quality, but how do they ensure it? Assess their testing processes. Rigorous quality checks and certifications matter. A manufacturer may have fancy equipment, but if they lack a thorough inspection system, their claims might be superficial. Ask about their quality control protocols. It reflects their dedication to excellence and can help you avoid regret later on.