Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

In the realm of advanced materials, selecting the appropriate Tungsten Solid for your project is crucial to ensure optimal performance and durability. Renowned industry expert Dr. Emily Carter, a leading materials scientist at the Institute of Metal Research, emphasizes the importance of this choice, stating, “The right Tungsten Solid can significantly enhance the efficiency and lifespan of your applications.” As Tungsten continues to gain traction across various sectors, from aerospace to defense, understanding the unique properties and specifications of different Tungsten Solids becomes indispensable for engineers and project managers alike.

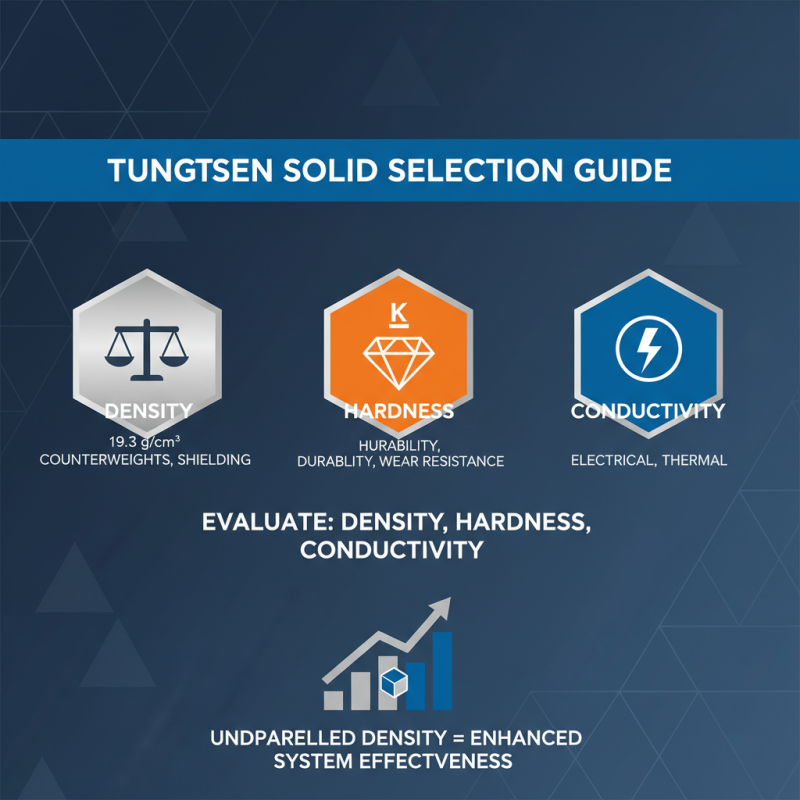

When evaluating which Tungsten Solid best suits your needs, it is essential to consider factors such as density, thermal conductivity, and mechanical strength. These attributes not only influence the material's performance under stress but also its compatibility with other elements in your design. Consequently, making an informed decision can lead to enhanced operational effectiveness and reduced costs in the long run. Thus, delving into the characteristics of Tungsten Solids and aligning them with your project's specific requirements is paramount for achieving success.

Tungsten solid is a crucial material in various industries due to its remarkable properties, including high density, exceptional hardness, and the ability to withstand extreme temperatures. The composition of tungsten primarily consists of tungsten metal, which boasts a melting point of 3422°C, making it suitable for applications in aerospace, defense, and manufacturing sectors. According to a report from the Global Tungsten Industry, the demand for tungsten solid has been steadily increasing, with forecasts predicting growth driven by its use in cutting tools and high-performance machinery.

When selecting the right tungsten solid for your project, understanding the specific properties is essential. Tungsten has a density of around 19.3 g/cm³, which contributes to its effectiveness in radiation shielding and counterbalancing applications. The hardness level of tungsten makes it ideal for producing durable components, while its excellent wear resistance enhances longevity and reliability in high-stress environments.

Tips:

1. Identify the application requirements: Assess the temperature and pressure conditions your project will face to select the appropriate tungsten solid with suitable thermal and mechanical properties.

2. Consider machining capabilities: Tungsten can be challenging to machine due to its hardness, so make sure you have the right tools and techniques in place to handle it effectively.

Tungsten solids are increasingly recognized for their versatility and essential role across various industry sectors, notably aerospace and medical applications. In the aerospace industry, tungsten’s high density, strength, and resistance to extreme temperatures make it an ideal material for components such as counterweights in aircraft and ballast in spacecraft. According to a report by ResearchAndMarkets, the demand for tungsten in aerospace is projected to grow significantly, driven by advancements in technology and the increasing need for lightweight, durable materials that enhance performance and fuel efficiency.

In the medical field, tungsten solids are utilized in radiation shielding and medical device manufacturing. Their high atomic number provides excellent protective properties against ionizing radiation, which is critical in environments such as hospitals and diagnostic imaging facilities. The global tungsten market for medical applications was valued at approximately $300 million in 2021 and is expected to witness steady growth as the medical device industry expands and the focus on patient safety intensifies. With the ability to provide robust protection while being biocompatible, tungsten solids offer unique advantages that meet the stringent requirements of healthcare applications.

When choosing the right tungsten solid for your project, it is essential to thoroughly evaluate the specific requirements related to density, hardness, and conductivity. Tungsten is renowned for its high density, typically around 19.3 g/cm³, making it an excellent choice for applications where weight is crucial, such as in counterweights or radiation shielding. According to industry reports, components made from tungsten can significantly improve the effectiveness of systems requiring heft without sacrificing size, due to its unparalleled density.

Hardness is another critical factor when selecting tungsten materials. Tungsten's hardness rating on the Mohs scale is around 7.5, which renders it highly resistant to scratching and denting. This property is vital in sectors such as aerospace and defense, where durability is paramount. Studies indicate that tungsten’s exceptional hardness can extend the lifespan of tooling and machinery parts, reducing downtime and increasing productivity.

Electrical conductivity should also be a primary consideration in your selection process. Although tungsten is not as conductive as metals like copper or aluminum, it holds a respectable electrical conductivity of approximately 29% of the International Annealed Copper Standard (IACS). This characteristic makes tungsten suitable for high-temperature applications, where other metals might fail. Evaluation of your project's specific conductivity needs will help in determining whether tungsten solids can meet the operational demands without compromising overall efficiency.

When considering materials for industrial applications, tungsten stands out due to its exceptional density and high melting point. These properties make it an ideal choice for industries that require materials to withstand extreme temperatures and pressures. However, it is essential to weigh the advantages of tungsten against alternative materials such as steel and lead. While steel offers greater flexibility and is widely used, it lacks the thermal stability that tungsten provides. Lead, on the other hand, is often considered for its radiation shielding capabilities, yet its weight can be a disadvantage in applications where reducing mass is critical.

The comparative analysis of tungsten and its alternatives often centers around performance and cost-effectiveness. Tungsten’s high hardness translates to greater wear resistance, which is vital in cutting and drilling tools. However, budget constraints could push some manufacturers to consider alternatives that, while less durable, may still meet the necessary performance criteria for less demanding applications. Understanding the specific requirements of each project will guide the decision-making process, ensuring that the selected material aligns with the performance needs without compromising on safety or integrity.

When budgeting for tungsten solid in engineering projects, it's essential to understand the cost factors that influence overall expenditure. Tungsten, being one of the densest and hardest metals available, can significantly impact project budgets primarily due to its raw material cost, manufacturing complexity, and price fluctuations in the market. According to the International Tungsten Industry Association (ITIA), the average market price for tungsten was around $300 per metric ton in recent years, but this can vary based on demand and extraction costs, which can soar during times of geopolitical instability.

In addition to raw material costs, the fabrication processes involved in shaping tungsten solid into usable components add another layer of expense. The high melting point of tungsten necessitates specialized equipment and techniques for machining, which can increase labor and operational costs. A report by Market Research Future highlights that the costs associated with the manufacturing processes can account for 40-60% of the total project budget. Therefore, when planning a project that incorporates tungsten solid, engineers must conduct thorough cost-benefit analyses, ensuring they account for both material sourcing and fabrication methods to maintain financial feasibility.