Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

Lathe inserts are crucial components in the machining industry. They enhance the efficiency and precision of various machining processes. According to expert John Smith, a leading figure in the lathe insert field, "The right lathe insert can change the game for any machinist."

These tools are designed to withstand high temperatures and wear. Their design can drastically impact the quality of the finished product. However, not all lathe inserts are created equal. Choosing the wrong type can lead to inefficiencies and increased costs. Machinists often find themselves grappling with the delicate balance between durability and performance.

There is a wide range of inserts available today. Each type serves a specific purpose and offers distinct benefits. Some inserts excel at roughing cuts, while others are better suited for finishing operations. It's essential to understand these differences to make informed decisions. Each choice carries its weight of consequences, urging machinists to reflect on their selections carefully.

Lathe inserts are vital for effective machining. These small tools are designed to cut and shape materials like metal or plastic. Each insert plays a specific role, enhancing accuracy and performance. They come in various shapes and materials, catering to different machining needs.

Choosing the right insert can be tricky. The geometry of the insert affects the cutting process. A wrong choice may lead to poor finishes or tool wear. Additionally, the material of the insert must match the workpiece to avoid problems. Some inserts work well with hard materials, while others suit softer ones. It's essential to consider these factors for optimal results.

Regular maintenance is crucial. Poor maintenance can lead to reduced efficiency. Inspecting inserts for chips or wear can prevent costly mistakes. Operators often overlook this, leading to unexpected downtime. Careful monitoring and replacement of worn inserts can significantly enhance machining success.

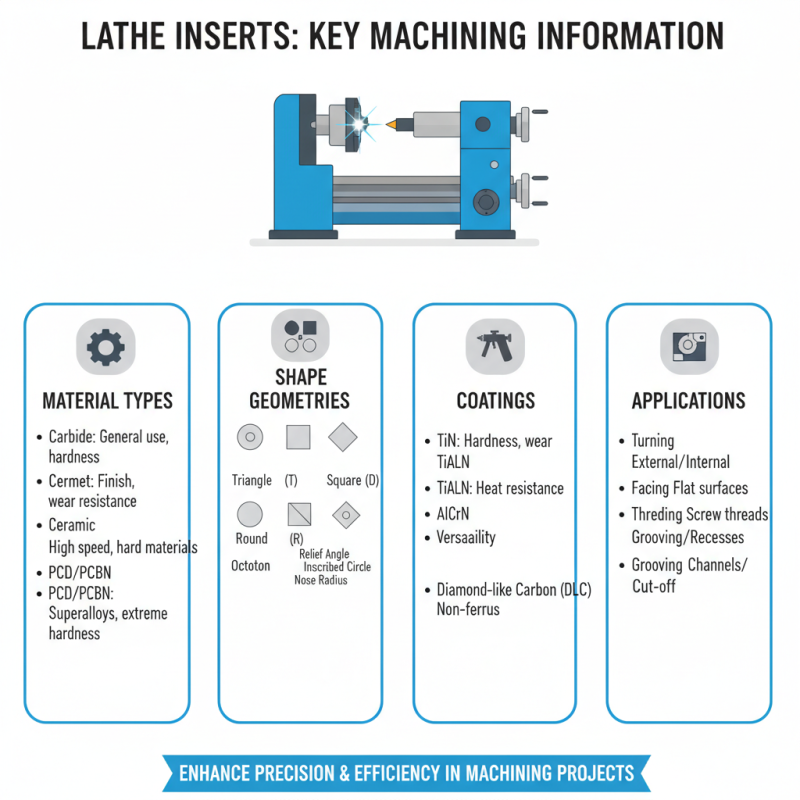

Lathe inserts play a critical role in machining success. Their material composition significantly impacts their performance. Different materials provide unique properties like hardness, wear resistance, and thermal stability. For example, carbide inserts are famous for offering excellent hardness. They withstand high temperatures well. However, they can be brittle, leading to breaking under excessive pressure. This fragility often gets overlooked.

Another common material is high-speed steel (HSS). HSS inserts are versatile and more resilient. They can endure shocks better than carbide. However, they wear out faster. This is a trade-off many machinists face. Choosing the right material hinges on the specific machining task at hand. Misjudging the suitable insert can lead to poor surface finish or frequent replacements.

Moreover, the coating on inserts also matters. Coatings enhance hardness and reduce friction. Looking closely at various coatings allows better decisions. Yet, it can be challenging to select the right one. Many machining operations fail because of improper insert choices. Often, the best options seem unclear under pressure. Continuous assessment and adaptation are necessary to refine insert selection.

Lathe inserts play a crucial role in machining. They come in various types, each suited for specific applications. Understanding these types can enhance precision and efficiency in projects.

There are several categories of lathe inserts. The most common ones include turning inserts, grooving inserts, and threading inserts. Turning inserts are designed for shaping and smoothing metal parts. They offer various shapes, like round or square, which cater to different needs. Grooving inserts are essential for creating narrow grooves and slots. They work well with materials like steel and aluminum.

Threading inserts, on the other hand, are specialized. They generate threads in cylindrical workpieces. The precision of these inserts is vital for ensuring proper fit and functionality. Each type has its own advantages and limitations. Understanding these can lead to better decision-making. Selecting the wrong insert can result in inefficiencies. Aiming for the right choice can cut down costs and time.

The selection of lathe inserts is critical for achieving optimal results in machining. Various factors come into play when choosing the right insert. Material type, geometry, and coating are three key contributors. Studies indicate that using the correct insert can boost productivity by up to 30%. However, many machinists still overlook these details.

Material choice can significantly impact tool life. For example, carbide inserts are often preferred due to their durability. But not every application requires that level of toughness. Sometimes, ceramic or high-speed steel inserts may provide sufficient performance. A report by a machining research group highlighted that 15% of tool failures are due to inappropriate material selection.

Geometry also plays a vital role. The insert shape affects chip formation and cutting efficiency. A well-chosen insert can reduce cutting forces and improve surface finish. Yet, simplified guidelines often lead machinists to make hasty decisions. Every application is unique and demands careful consideration of various geometries. Furthermore, coatings can enhance wear resistance, but they are not universally effective. Hence, the importance of testing different combinations can't be overstated.

Lathe inserts play a vital role in machining processes. They directly influence both productivity and cost efficiency. When using the right insert, machining time can be significantly reduced. A well-designed insert cuts more efficiently, thus saving energy and reducing tool wear. Machinists often overlook the importance of insert selection. However, the wrong choice can lead to wasted materials and time.

Improper inserts result in poor surface finishes. This may require additional finishing processes, increasing overall costs. A high-quality insert can enhance dimensional accuracy. It creates smoother finishes and reduces the likelihood of defects. Investing in the correct insert is crucial. It is worth evaluating various options to maximize performance.

Machining environments can be tough. Heat and pressure often wear down tools quickly. Inserts can be designed to withstand these conditions. They can be made from advanced materials that endure higher temperatures. However, even the best inserts require regular monitoring. Failing to track their wear can lead to production delays. Understanding the need for change is essential for sustained success.

| Insert Type | Material | Application | Tool Life (Hours) | Cost Efficiency (%) |

|---|---|---|---|---|

| Cermet Inserts | Cermet | Finishing | 60 | 15 |

| Carbide Inserts | Carbide | Roughing | 50 | 20 |

| High-Speed Steel Inserts | HSS | General Purpose | 40 | 10 |

| Ceramic Inserts | Ceramic | High Speed Finishing | 30 | 25 |

| PVD Coated Inserts | HSS with PVD Coating | Aluminum Machining | 55 | 18 |