Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

In the competitive world of manufacturing, maximizing machining efficiency is crucial for reducing costs and improving productivity. One effective strategy that has garnered industry attention is the use of Tungsten Carbide Inserts. According to a report by the International Cutting Tool Association, the implementation of advanced carbide tooling can increase operational efficiency by up to 35%, while also enhancing tool life and surface finish quality. Tungsten Carbide Inserts offer superior hardness and wear resistance, making them ideal for high-speed machining operations across various materials, including steel and aluminum. As manufacturing processes continue to evolve, optimizing the use of these inserts not only improves performance but also aligns with the industry's push for sustainable practices by reducing waste and energy consumption. By focusing on the strategic application of Tungsten Carbide Inserts, manufacturers can achieve significant gains in their machining operations.

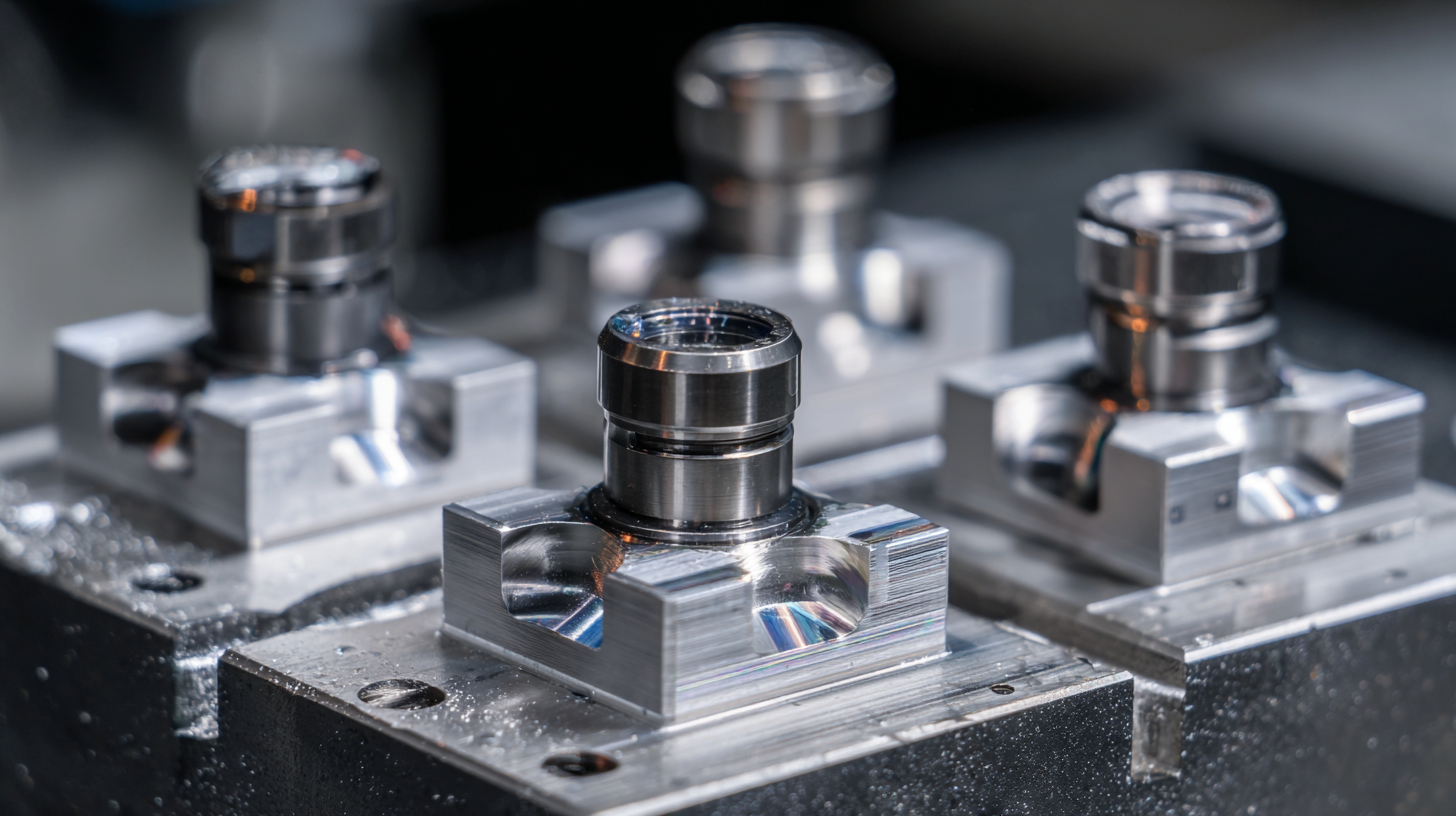

Tungsten carbide inserts have gained significant traction in the machining industry due to their outstanding performance and durability. These inserts exhibit exceptional hardness, allowing them to withstand high temperatures and resist wear, which is crucial in maintaining cutting efficiency over time. The ability of tungsten carbide to retain its cutting edge in demanding conditions translates to longer tool life and reduced downtime for replacements, ultimately enhancing productivity in manufacturing processes.

Additionally, tungsten carbide inserts facilitate higher cutting speeds and feed rates, enabling machinists to achieve superior surface finishes and tighter tolerances. This efficiency is particularly advantageous in production environments where time is of the essence. By utilizing these inserts, manufacturers can optimize their machining processes, reduce scrap rates, and improve overall operational efficiency. Understanding the technical advantages of tungsten carbide inserts positions businesses to make informed decisions, thereby maximizing their machining capabilities and ensuring a competitive edge in the industry.

Selecting the right tungsten carbide inserts is crucial for optimizing machining efficiency in various manufacturing applications. Tungsten carbide inserts are known for their hardness and wear resistance, making them ideal for metal cutting processes. When choosing inserts, one must consider factors such as the material being machined, the type of machining operation, and the desired surface finish. For instance, harder materials may require inserts with a tougher substrate and a sharper edge geometry to enhance performance and prolong tool life.

Additionally, the coating of the tungsten carbide inserts plays a significant role in their effectiveness. Coatings such as titanium nitride (TiN) or titanium carbo-nitride (TiCN) can provide improved wear resistance and reduced friction, which greatly contributes to maintaining cutting edge sharpness during prolonged operations. It’s also essential to match the insert’s geometry with the specific application; for operations requiring high precision, insert types with finer edge radii are preferred, whereas those handling rougher cuts may benefit from more robust geometries. Ultimately, a thoughtful selection process will lead to better machining outcomes and increased productivity.

Optimizing cutting parameters is essential for enhancing machining efficiency when using tungsten carbide inserts. According to data from the American Society of Mechanical Engineers (ASME), selecting the right cutting speed can increase tool life by up to 50% while reducing cycle times by as much as 30%. This is particularly important in high-volume manufacturing environments where every second counts and any delay can lead to significant cost implications.

Additionally, adjusting feed rates and depth of cut can further maximize productivity. The Metal Cutting Institute suggests that a combination of increased feed rates and optimal depth of cut can result in a material removal rate that is 20% higher than traditional machining methods. For instance, utilizing a feed rate of 0.4 mm/rev in tandem with an appropriate cutting speed of 200-300 m/min can dramatically improve the efficiency of machining processes, particularly for tough materials. By carefully analyzing and adjusting these parameters, manufacturers can harness the full potential of tungsten carbide inserts, leading to improved machining performance and reduced operational costs.

To maximize machining efficiency with tungsten carbide inserts, proper tool maintenance and longevity practices are essential. Regularly monitoring tool wear and implementing a preventive maintenance schedule can significantly enhance performance. According to a report from the Machining Industry Association, tools that are adequately maintained experience a 30% increase in operational life compared to those that are neglected. This not only reduces costs associated with frequent tool replacement but also improves overall productivity on the shop floor.

Moreover, the use of appropriate cutting parameters tailored to the specific material being machined is crucial. A study by the International Journal of Advanced Manufacturing Technology shows that optimizing feed rates and cutting speeds can lead to a decrease in tool wear rates by up to 20%. These best practices enable manufacturers to achieve high precision while extending the life of tungsten carbide inserts, ultimately resulting in greater machining efficiency and reduced downtime. Regular inspections, along with proper storage of tools, will further ensure that these inserts remain in optimal condition for longer durations.

Maximizing machining efficiency is essential for competitive manufacturing, and the performance metrics of tungsten carbide inserts play a pivotal role in this process. Studies have shown that using high-quality tungsten carbide inserts can enhance cutting speeds by up to 50% compared to conventional inserts. This significant increase allows for higher productivity levels and reduced cycle times, which are crucial in meeting tight production schedules.

Moreover, analyzing metrics such as tool wear, surface finish, and dimensional accuracy reveals valuable insights into improving machining outcomes. Industry reports indicate that utilizing advanced coatings on tungsten carbide inserts can lower tool wear rates by as much as 30%, leading to longer insert life and decreased downtime for tool changes. By continuously monitoring these performance metrics, manufacturers can make data-driven decisions that optimize their machining processes, resulting in cost savings and improved product quality. As businesses aim to streamline operations, the role of performance analysis in the application of tungsten carbide inserts cannot be overstated.