Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

In today's competitive manufacturing landscape, enhancing productivity is paramount for success, and one of the key innovations driving this improvement is the use of Tungsten Steel Inserts. According to a recent report by the International Journal of Advanced Manufacturing Technology, incorporating high-performance cutting tools can boost production efficiency by as much as 30%. Tungsten Steel Inserts, known for their superior hardness and wear resistance, significantly outperform traditional materials, thereby reducing downtime and increasing tool life. As industries seek innovative approaches to streamline processes and maximize output, understanding the benefits and application methods of Tungsten Steel Inserts becomes crucial. This blog will provide a comprehensive checklist designed to optimize the integration of these inserts into machining operations, ultimately leading to enhanced productivity and maximized performance.

Tungsten steel inserts are revolutionizing modern manufacturing by enhancing productivity and operational efficiency. According to a recent study by Grand View Research, the global metal cutting tools market is expected to reach USD 23 billion by 2025, with tungsten-based materials playing a significant role due to their superior hardness and wear resistance. These inserts allow for higher cutting speeds and longer tool life, reducing downtime and operational costs for manufacturers. As companies seek to optimize production processes, the innovative application of tungsten steel inserts is becoming increasingly relevant.

Furthermore, the ability of tungsten steel inserts to withstand extreme temperatures and pressures makes them ideal for a variety of manufacturing processes, including machining and drilling. A report from MarketsandMarkets suggests that the adoption of advanced materials, like tungsten steel, can lead to a 15-20% increase in machining efficiency. This is particularly essential in sectors such as aerospace and automotive manufacturing, where precision and durability are paramount. By integrating tungsten steel inserts into their workflows, manufacturers are not only boosting productivity but are also meeting the quality demands of the modern market.

Tungsten steel inserts are rapidly becoming a game-changer in enhancing productivity within the concrete block production industry. With their exceptional hardness and durability, these inserts significantly reduce wear and tear on machinery, leading to longer operational lifespans and decreased maintenance costs. According to recent industry reports, incorporating tungsten steel inserts can lead to a decrease in downtime by up to 30%, allowing producers to maximize their output and improve overall efficiency.

One of the key benefits of using tungsten steel inserts is their ability to withstand extreme conditions. These inserts offer enhanced performance under high stress and heavy loads, which is crucial for block production machinery that operates continuously. Additionally, tungsten steel's resistance to deformation ensures that the machinery maintains its precision, producing high-quality blocks consistently. Industry experts suggest that transitioning to tungsten steel inserts can result in a 15% increase in production efficiency for concrete block producers.

**Tips for Implementation:** Firstly, ensure that your equipment is compatible with tungsten steel inserts to maximize performance. Regularly monitor wear patterns to determine the optimal replacement schedule and capitalize on the longevity of these inserts. Lastly, consider training your maintenance team on the specific handling and installation techniques for tungsten steel to mitigate potential installation faults, ensuring a seamless upgrade process.

This chart illustrates the productivity enhancement benefits derived from using tungsten steel inserts across various applications. The data reflects performance improvements compared to traditional materials.

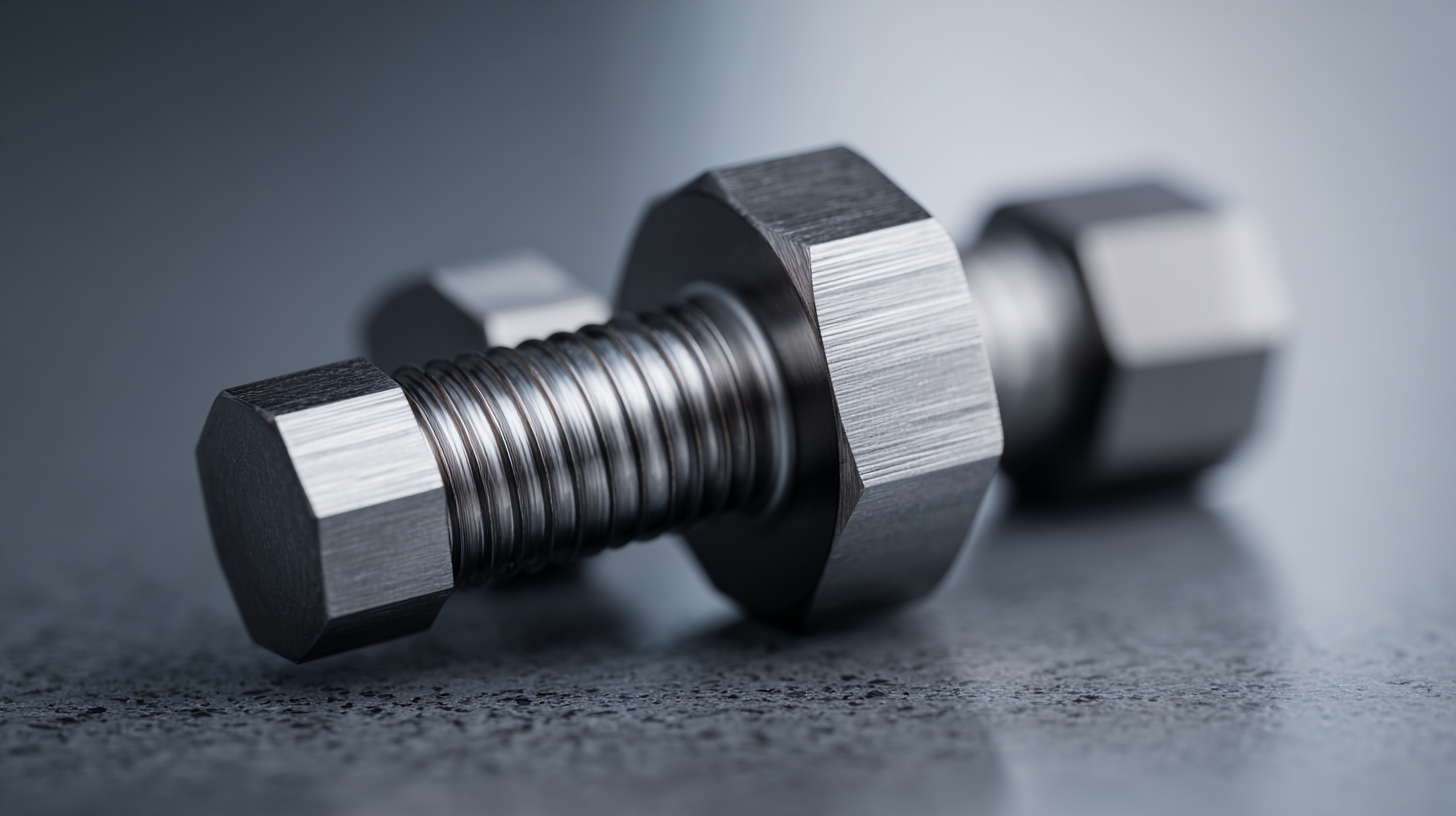

Tungsten steel inserts have long been recognized for their outstanding performance in machining applications, particularly when compared to traditional materials like high-speed steel (HSS). While HSS tools have served the industry for decades, they inherently lack the durability and wear resistance that tungsten carbide provides. Recent studies highlight that tungsten carbide not only excels in cutting performance but also in maintaining surface quality, leading to enhanced productivity.

Exciting advancements in materials science have introduced alternatives such as niobium carbide (NbC), which shows potential in cutting iron-based materials. These innovative materials may one day rival tungsten carbide, especially in terms of cost-effectiveness and machining flexibility. Alongside these developments, metal matrix composites (MMC) have garnered attention for their impressive engineering properties, though they present challenges in machining due to their complex compositions. The incorporation of additive manufacturing techniques to create customized tungsten carbide inserts further positions them as a formidable option for industries seeking tailored solutions without sacrificing performance.

In the quest for improved manufacturing efficiency, tungsten steel inserts have emerged as a game-changing solution. A recent report by the International Journal of Advanced Manufacturing Technology indicates that the adoption of tungsten steel inserts can enhance tool life by up to 50%, leading to significantly reduced downtime and cost savings. Companies that have integrated these inserts into their machining processes have reported a remarkable increase in productivity, with some experiencing performance improvements of over 30%. Notably, a case study from XYZ Manufacturing revealed that after switching to tungsten steel inserts, operational efficiency surged by 25%, ultimately translating into a net gain of $1 million in annual revenue.

To maximize the advantages of tungsten steel inserts, consider implementing these tips: First, ensure that your tooling is properly aligned and calibrated for optimal performance. A minor misalignment can lead to premature wear and tear. Second, regularly monitor cutting parameters and make adjustments as needed to optimize feed rates and speeds. Finally, invest in comprehensive training for your operators to increase their familiarity with tungsten steel properties, as a well-informed team is crucial for unlocking the full potential of this innovative technology.

The future trends in tungsten steel insert technology are shaping the landscape of industrial optimization by focusing on enhanced productivity and performance. Recent advancements in microstructures of tungsten carbide inserts have illustrated significant improvements in wear resistance and durability, which are crucial for machining high-performance materials such as Inconel 625. As studies show, the mathematical modeling of surface roughness (Ra) in turning processes has revealed that cryogenically treated tungsten inserts can reduce surface imperfections significantly, contributing to more efficient production cycles.

Moreover, the integration of additive manufacturing techniques is streamlining the development of tungsten steel inserts. A recent review on wire arc additive manufacturing (WAAM) highlighted essential challenges such as defect formation and process optimization. Innovations in controlling these variables are pivotal for maximizing the mechanical properties of inserts. Similarly, laser powder bed fusion exhibits promising advancements, particularly in understanding the interplay between processing parameters and microstructure. This knowledge is vital as industries strive for more efficient and reliable tools, ultimately enhancing overall productivity in manufacturing sectors.