Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

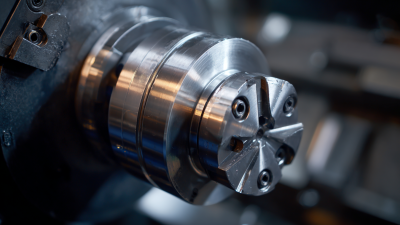

In the realm of precision engineering, the significance of lathe inserts cannot be overstated. These small yet powerful tools are fundamental in achieving high-quality machining operations, contributing to improved efficiency and accuracy in manufacturing processes. According to a report by Allied Market Research, the global market for cutting tools, including lathe inserts, is projected to reach $36.8 billion by 2027, reflecting a robust growth fueled by innovations and the increasing demand for precision parts across various industries.

Understanding how to select, utilize, and maintain lathe inserts is essential for engineers and machinists alike, as these components play a crucial role in optimizing productivity and extending tool life. In this beginner's guide, we will explore the various types of lathe inserts available, their applications, and best practices for incorporating them into modern machining processes.

Lathe inserts are crucial components in precision engineering, designed to enhance the efficiency and effectiveness of machining operations. These inserts can be categorized into various types depending on their material, geometry, coating, and application. The primary types include solid carbide inserts, ceramic inserts, and coated inserts. Each type possesses unique characteristics, making them suitable for specific machining tasks. For instance, solid carbide inserts offer excellent wear resistance and are ideal for high-speed machining, while ceramic inserts excel in hard materials due to their high temperature resistance.

When selecting lathe inserts, it is essential to consider the specific requirements of your project. Tips for choosing the right type include assessing the material you will be machining, determining the required surface finish, and understanding the cutting conditions, such as speed and feed rates. Additionally, manufacturers often provide color-coding systems that can simplify the selection process. These color codes give a quick reference to the insert's material and intended application, allowing for more efficient tool selection.

Another important aspect of lathe inserts is their role in cost-effectiveness. Investing in high-quality inserts may seem more expensive initially, but they can significantly reduce downtime and tooling costs in the long run. As the CNC machine market continues to grow, understanding the variety and applications of lathe inserts becomes increasingly vital for staying competitive in precision engineering.

| Insert Type | Material | Application | Advantages |

|---|---|---|---|

| Trade Inserts | Cemented Carbide | General Turning | High wear resistance, good surface finish |

| Grooving Inserts | Cermet | Grooving Operations | Excellent finish, heat-resistant |

| Profiling Inserts | Ceramic | Profiling and Contouring | High temperature strength, long tool life |

| Parting Inserts | High-Speed Steel | Parting and Inserting | Good toughness, reliable performance |

| Turning Inserts | PKD (Polycrystalline Diamond) | Finish Turning | Superior wear resistance, excellent surface finish |

Lathe inserts play a crucial role in precision machining, providing several key benefits that enhance manufacturing efficiency and product quality. One of the primary advantages of using lathe inserts is their ability to maintain consistent cutting performance over extended periods, which is vital for high-volume production environments. Their replaceable nature allows for minimal downtime during tool changes, significantly improving overall productivity. With the global CNC machine tools market projected to grow substantially, the adoption of advanced lathe inserts is becoming increasingly important for meeting the demand for high-precision components.

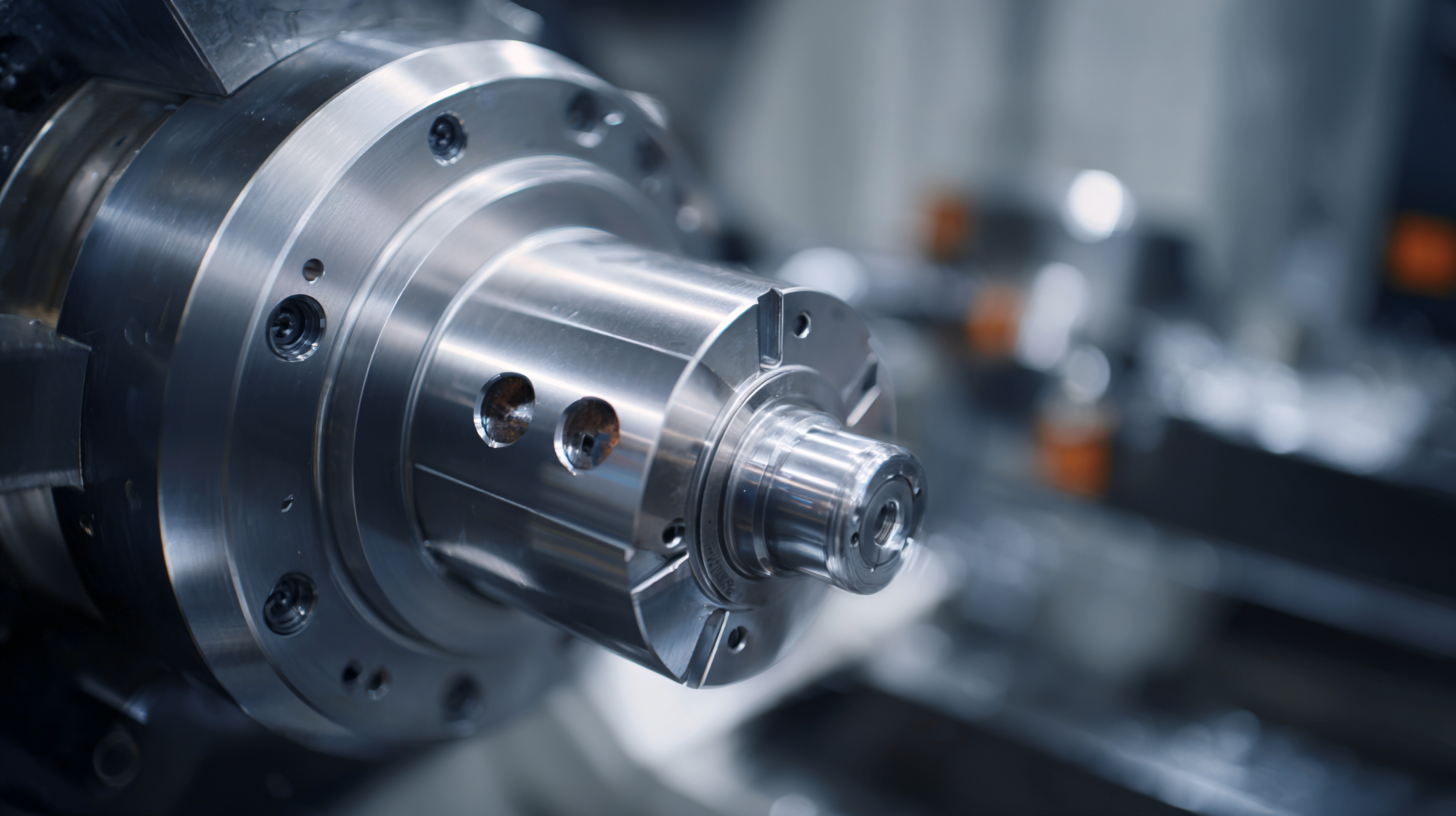

Furthermore, the integration of AI technology into CNC machining is redefining how lathe inserts are utilized. The use of AI not only enhances the performance of cutting tools but also allows for better predictive maintenance, which can prevent unexpected failure during machining operations. As the market evolves, manufacturers focusing on high-precision and multi-axis machining centers will increasingly rely on lathe inserts to achieve superior results. This trend highlights the essential role that lathe inserts play in ensuring competitive advantages within the rapidly advancing precision engineering landscape.

When embarking on a precision engineering project, selecting the right lathe insert is crucial for achieving optimal results. One of the first tips is to consider the material you will be working with; different materials require specific insert geometries and coatings to ensure durability and precision. For instance, carbide inserts are ideal for machining hard metals, while ceramic inserts excel in high-speed applications.

Another important factor is the insert's shape and size. Inserts come in various shapes such as square, round, and triangular, each catering to different cutting styles and depths. A square insert may allow for more stability and versatility, while a round insert could provide smoother finishes. Additionally, always pay attention to the cutting edge geometry, as it can greatly influence the cutting action and surface finish.

Lastly, keep the cutting conditions in mind, including feed rate and speed. A higher RPM might suit harder materials but may also require inserts that have been specifically designed to withstand the resulting stress. By carefully considering these factors, you can select the right lathe insert, ensuring greater efficiency and precision in your engineering projects.

When working with lathe inserts in precision engineering, beginners often overlook several critical mistakes that can compromise both their work and tooling longevity. One common error is failing to select the appropriate insert geometry and material for the specific application. According to industry reports, incorrect insert choice can result in 30% more tool wear and negatively affect surface finish, leading to costly rework and wasted materials.

Another frequent mistake is improper tool setup, including incorrect alignment or insufficient clamping force. These missteps can cause vibration and chatter, which not only deteriorate the quality of the finished part but also shorten insert life. Statistics suggest that tool setup errors can lead to a performance drop of up to 50% during machining operations. Additionally, neglecting to maintain proper cutting parameters, such as feed rate and spindle speed, can cause further complications, ultimately impacting productivity and increasing operational costs. Employing best practices and preventive measures is crucial for ensuring optimal performance and precision in lathe operations.

This chart illustrates the impact of various lathe insert materials on machining performance, highlighting mistakes to avoid for optimal results.

To maximize the lifespan and performance of lathe inserts, proper maintenance is critical. According to a report by the International Journal of Advanced Manufacturing Technology, the quality of tool maintenance can lead to a performance enhancement of up to 30% in precision machining operations. Regular inspection for wear and tear can help identify any abnormalities early on, allowing operators to replace inserts before they can affect the overall machining process.

Lubrication also plays a vital role in extending the life of lathe inserts. A study conducted by the Machinery Lubrication magazine found that using the appropriate cutting fluids can reduce tool wear by up to 50%, significantly improving tool life. Additionally, maintaining optimal cutting speeds and feeds tailored to specific materials ensures that inserts operate under the best conditions, further reducing wear and tear. Adopting systematic cleaning practices to eliminate chip buildup and coolant deposits is another essential maintenance strategy that enhances the longevity and reliability of lathe inserts.