Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

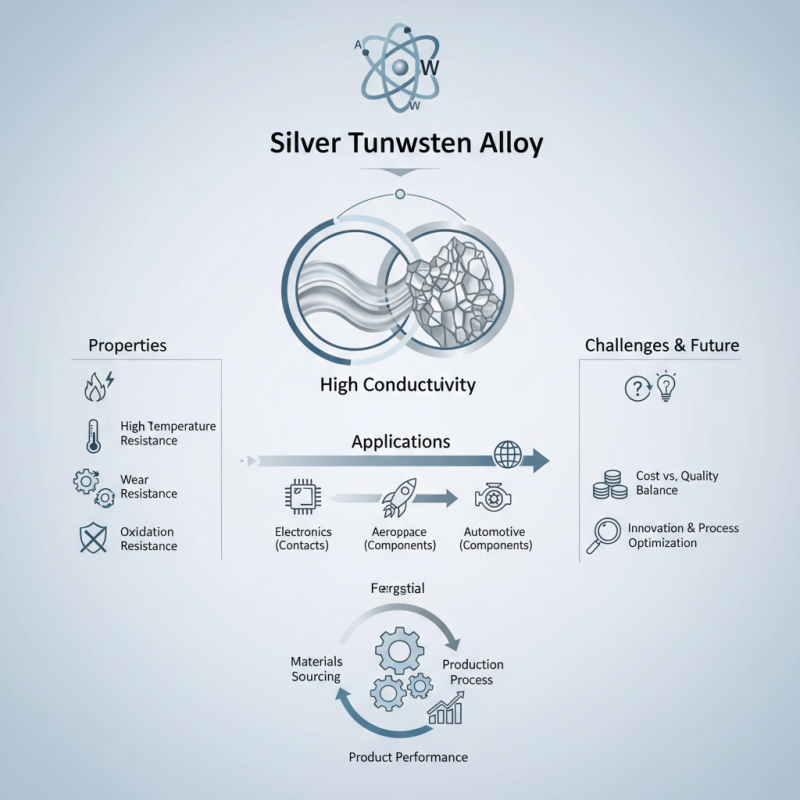

The Silver Tungsten Alloy is a remarkable material praised for its unique properties. This alloy combines the high conductivity of silver with tungsten's strength. Together, they create a compound that excels in extreme conditions. Its resistance to wear and high temperatures makes it suitable for various applications.

In electronics, for instance, the Silver Tungsten Alloy is used in contacts. These contacts endure harsh environments and maintain performance. Its intriguing ability to withstand oxidation is also noteworthy. Though widely explored, some aspects remain open to improvement. How can manufacturers optimize its production process?

Applications extend beyond electronics to aerospace and automotive fields. The Silver Tungsten Alloy's durability ensures reliability in crucial components. Despite its advantages, costs can be a concern. Industry leaders must balance quality with affordability. There’s room for innovation and exploration in the realm of Silver Tungsten Alloy.

Silver tungsten alloy is gaining traction in various industries, primarily due to its remarkable properties. This alloy mainly consists of tungsten and silver, typically around 90% tungsten and 10% silver. The combination provides high electrical conductivity and excellent thermal stability. Such properties make it a favorite for applications in electrical contacts and specialized industrial equipment.

The hardness of silver tungsten alloy is notable, rated at around 80 HRA. This makes it suitable for high-wear environments. Furthermore, it has a melting point exceeding 3000°C, ensuring stability under extreme conditions. However, forming this alloy can be challenging due to its high density. Production methods often need refining, as imperfections can decrease performance.

Tips: When selecting silver tungsten for your application, assess the specific thermal and electrical needs. Understand the required quality control standards, too. Remember, even small impurities can critically affect its performance. Consider pilot testing to avoid operational pitfalls. Adjustments in composition may sometimes yield better results, reflecting the need for exploration in material science.

| Property | Value | Applications |

|---|---|---|

| Electrical Conductivity | High (up to 60% IACS) | Electrical contacts |

| Thermal Conductivity | Excellent | Heat sinks |

| Density | Approx. 18 g/cm³ | High-performance applications |

| Hardness | High (Rockwell hardness: 80-90) | Sparking electrodes |

| Melting Point | Approx. 1500 °C | High-temperature applications |

Silver tungsten alloy exhibits exceptional electrical conductivity, making it ideal for industrial applications. The alloy combines the high conductivity of silver with the strength and wear resistance of tungsten. In fact, silver tungsten can have an electrical conductivity of around 40% IACS. This metric positions it as a top choice for electrical contact materials.

In industrial settings, silver tungsten is commonly used in switches, relays, and circuit breakers. Its ability to withstand weld and arc erosion enhances durability in high-load environments. Recent industry reports indicate that devices using silver tungsten contacts experience fewer failures. This improves overall reliability and reduces maintenance costs.

Tips: When selecting materials for electrical applications, consider both conductivity and mechanical strength. Analyze performance data from similar applications to avoid common pitfalls. Regular testing can help identify issues before they escalate, ensuring operational efficiency.

Silver tungsten alloys displayed exceptional thermal resistance, making them ideal for numerous applications. These alloys can withstand high temperatures without degrading. The thermal conductivity of silver tungsten allows heat to dissipate quickly, preventing overheating in electrical contacts.

In applications involving electrical switches and connectors, silver tungsten is often preferred for its ability to maintain performance under heat. These alloys resist melting and wear, even in demanding environments. However, one may question their long-term efficiency under continuous thermal stress. There are instances where exposure to extreme conditions leads to unexpected failures. Understanding these limitations is crucial.

The combination of silver and tungsten creates a unique balance of properties. While boasting excellent thermal performance, there are challenges in processing these materials. Machining silver tungsten can be difficult, requiring specialized tools. Adjustments in manufacturing processes may be necessary, highlighting room for improvement. As industries evolve, the need for reliable, high-performance materials remains pressing.

Silver tungsten alloy is known for its remarkable properties, particularly in electrical contacts. These materials often contain 60% tungsten and 40% silver, providing excellent conductivity and resistance to wear. In electrical applications, they withstand high temperatures and arcing. According to a recent industry report, devices made with silver tungsten alloys can improve efficiency by over 30%. Such advantages lead to widespread use in circuit breakers and relay systems.

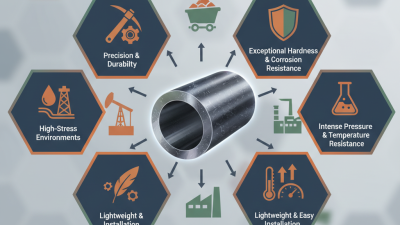

In addition to electrical contacts, silver tungsten alloy is used in various sectors. It is found in aerospace, automotive, and military applications. These alloys function well in high-stress environments. They resist erosion better than many substitutes. However, the production process can produce waste. Manufacturers must ensure sustainable practices. There’s often a balance between performance and environmental impact. Adjusting the tungsten-to-silver ratio can tailor properties, but this can lead to unpredictable results. Developers face challenges in optimizing these materials for specific tasks.

Silver tungsten alloy is known for its unique properties. It offers exceptional wear resistance and high thermal stability. These qualities make it suitable for various applications, including electrical contacts and aerospace components. Compared to other metal alloys, silver tungsten stands out. It has a higher melting point, which enhances its durability.

One notable advantage is its excellent electrical conductivity. This makes silver tungsten an ideal choice for switches and relays in electronics. Additionally, its low thermal expansion reduces the risk of damage in extreme conditions. Unlike conventional metal alloys, silver tungsten maintains its strength even when subjected to thermal stress. However, its cost can be a downside for some manufacturers.

Overall, the versatility of silver tungsten alloy in high-stress environments is impressive. Its unique properties enable it to perform reliably where others may fail. While it is not perfect and may require careful consideration for specific uses, its benefits often outweigh these concerns. The growing demand for efficient materials makes silver tungsten an alloy worth exploring.