Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

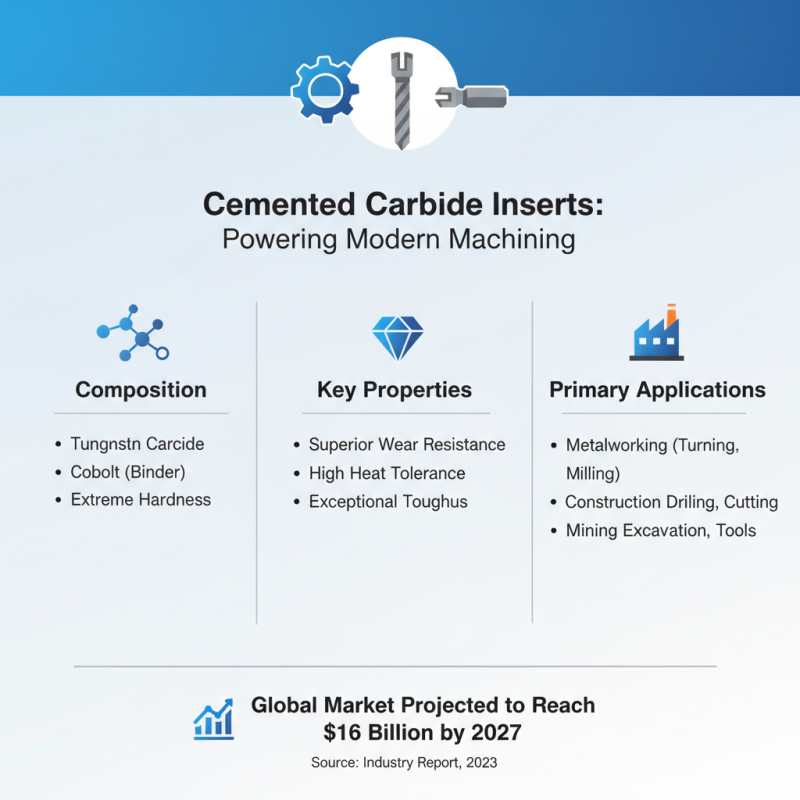

Choosing the right Cemented Carbide Inserts can significantly impact manufacturing efficiency. This material is renowned for its hardness and wear resistance. According to industry reports, cemented carbide comprises 75% tungsten carbide and 25% cobalt. This combination enhances toughness and overall performance.

There are various factors to consider when selecting these inserts. Tool geometry, coatings, and application type all play crucial roles. A wrong choice may lead to premature wear or tool failure. In fact, reports suggest that improper insert selection can result in a 30% decrease in machining efficiency.

Despite their advantages, not all cemented carbide inserts are created equal. Quality can vary among manufacturers. Evaluate the specifications and choose inserts that align with your specific needs. In the end, a thoughtful selection process can lead to enhanced performance and cost savings.

Cemented carbide inserts are essential tools in machining and cutting processes. Made from tungsten carbide and cobalt, these inserts provide excellent wear resistance. They are widely used in metalworking, construction, and even mining. According to a recent industry report, the global market for cemented carbide is projected to reach USD 16 billion by 2027. This growth reflects their significant role in various applications.

Understanding your specific needs when selecting inserts can be challenging. For instance, the cutting speed and material type drastically affect performance. It's crucial to assess the intended application before making a decision. Tips: Always consider the environment in which the insert will be used. Is your workpiece soft or hard? Adjust your insert type according to the material's characteristics.

Furthermore, lack of proper knowledge can lead to costly mistakes. A misjudged insert can cause increased wear on tools and parts. This can negatively impact productivity and precision. Tips: Do thorough research and consult industry standards. Analyze cutting data closely. Gathering as much information as possible will help in making informed choices. Remember, selecting the right insert can improve efficiency and product output significantly.

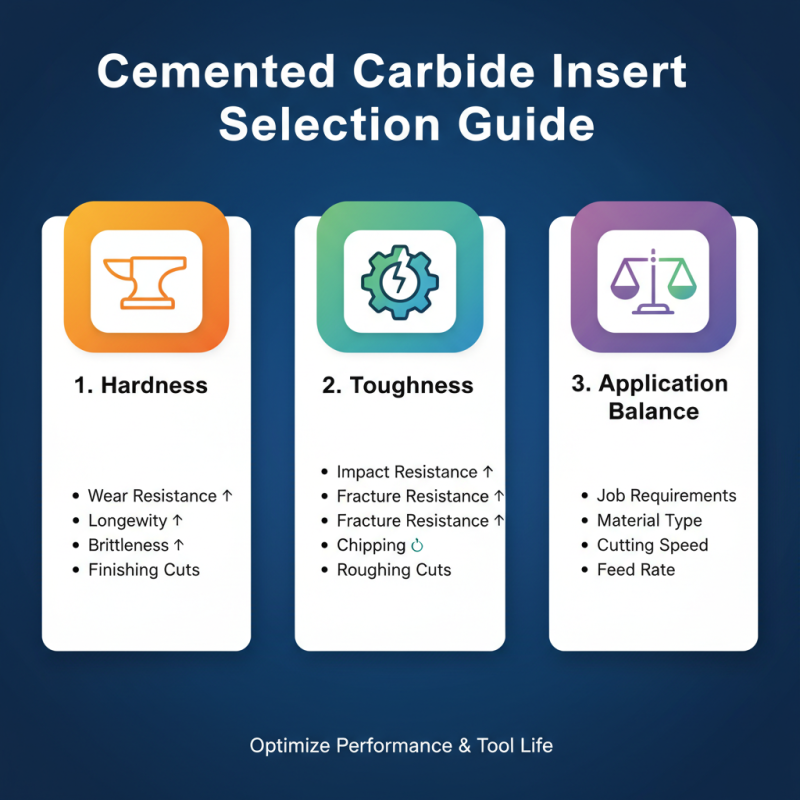

When selecting cemented carbide inserts, one must consider several key factors. The material's hardness plays a critical role. Harder inserts typically provide better wear resistance and longevity. However, softer materials might offer more toughness for specific applications. It’s crucial to balance these properties based on the job requirements.

Another important aspect is the insert geometry. The shape and size influence cutting performance and chip control. For example, a sharper edge can improve cutting efficiency but may reduce durability. Operators should evaluate the trade-off based on their specific needs. Additionally, coating types also matter. Coatings can enhance performance but may not be necessary for every application.

Finally, the intended application should always guide the selection process. Understanding whether the task involves roughing or finishing can make a huge difference. Too often, users overlook the importance of application context. Reflection on prior experiences can help in making a more informed choice. Making adjustments based on previous mistakes leads to better outcomes in the long run.

Cemented carbide inserts come in various types, suited for different applications. Each type has its own qualities, making it essential to understand the specific uses. For instance, grades designed for turning applications often feature a combination of hardness and toughness. This balance helps in machining materials like steel effectively. Meanwhile, those used for milling tend to focus more on edge strength.

When selecting your insert, consider the material being machined. Harder materials require tougher inserts. Some inserts excel in high-speed operations. Others are better for general-purpose tasks. It’s interesting how a small change in insert geometry can affect performance significantly. Many users overlook this aspect.

Not all inserts perform equally well in varied conditions. Factors like heat and pressure can influence their effectiveness. Users frequently face challenges with wear rates and chip formation. Thus, experimenting with different types can lead to better outcomes. Understanding your machining environment can make a difference. Each application reveals unique requirements and potential pitfalls.

This bar chart illustrates the various applications of cemented carbide inserts in machining processes. The percentages indicate the relative usage across different types of inserts such as face milling, turning, drilling, reaming, and grinding. Choose the right insert type based on your specific machining needs.

When evaluating the quality and performance of cemented carbide inserts, several factors come into play. These inserts are crucial for effective machining operations. Look for the insert's hardness and wear resistance. These properties greatly influence tool life and productivity. Abrasion characteristics matter a lot in high-speed conditions. The wrong choice can lead to quick wear and costly downtimes.

Tip: Always check the coating. A good coating enhances performance and resistance. It can improve chip removal and reduce friction. Testing various coatings may yield surprises in results.

Another vital factor is the geometry of the insert. Different designs serve specific applications. Assess the insert shape for your machining method. Consider the chip flow and cutting edge design. A mismatch can lead to poor performance and increased tool failure. Quality inserts generally have tight tolerances and refined edges.

Tip: Don't just fixate on price. A cheaper insert might save money but often at the cost of performance. Think long-term savings instead. Sometimes, investing more initially will deliver greater returns through increased productivity.

| Insert Type | Material Grade | Application | Cutting Speed (m/min) | Expected Tool Life (min) | Coating Type |

|---|---|---|---|---|---|

| General Purpose | K10 | Turning | 150 | 30 | Uncoated |

| High-Performance | K20 | Milling | 200 | 50 | TiN Coated |

| Toughness Optimized | K30 | Drilling | 100 | 40 | AlTiN Coated |

| Wear Resistant | K40 | Finishing | 250 | 60 | TiAlN Coated |

Cemented carbide inserts are known for their cost-effectiveness and impressive longevity. Recent industry reports indicate that these inserts can outlast conventional cutting tools by up to 10 times. This durability significantly reduces material costs over time. In a production environment, fewer insert replacements mean less downtime and higher efficiency.

When choosing cemented carbide inserts, consider their specific application. Different grades are available to handle various materials, from steel to harder composites. It's essential to match the insert with your machining task. For example, a hard alloy insert may not be ideal for softer metals. This mismatch can lead to premature wear and wasted resources.

Tip: Regularly assess the performance of your tools. Monitor wear patterns closely. This can help identify when to switch out inserts, maximizing lifespan. Additionally, analyze your production needs. Sometimes, investing slightly more upfront in high-quality inserts can lead to significant savings in the long run. Overall, understanding the specific demands of your production can truly make a difference.