Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

When it comes to selecting the right Tungsten Inserts for your specific needs, making an informed choice is essential for maximizing performance and durability. As industry expert John Smith, a leading authority in material science, wisely noted, “The right Tungsten Inserts can dramatically enhance the efficiency and longevity of your applications.” This statement underscores the significance of understanding the various factors that influence the effectiveness of Tungsten Inserts in different contexts, ranging from industrial applications to specialized manufacturing processes.

Choosing the correct Tungsten Inserts involves assessing various criteria, including density, hardness, and compatibility with existing tools and machines. It's not just about picking the most robust option; rather, it’s about finding an insert that aligns with your operational requirements and intended use. By navigating the complexities of material selection with expert guidance, users can ensure that they are utilizing Tungsten Inserts that offer unparalleled performance and reliability.

In this guide, we will explore the top tips for choosing the right Tungsten Inserts tailored to your needs, drawing from industry insights and practical considerations. By the end, you'll be equipped with the knowledge necessary to make well-informed decisions and elevate your operational capabilities in this specialized domain.

Tungsten inserts are renowned for their exceptional properties, making them a popular choice in various applications, particularly in high-performance environments. Composed primarily of tungsten, these inserts are designed to withstand high temperatures and pressures while maintaining their structural integrity. Tungsten's high density contributes to the effectiveness of these inserts, providing optimal weight distribution and enhancing performance in various tools and machinery. In addition, the material's exceptional hardness ensures longevity, allowing tungsten inserts to remain effective even in the face of severe wear and tear.

The benefits of tungsten inserts extend beyond their durability. Their ability to conduct heat and resist thermal expansion makes them ideal for scenarios where temperature fluctuations are prevalent. Furthermore, tungsten’s high melting point ensures that these inserts can maintain functionality in extreme conditions without deforming. The versatility of tungsten allows for the creation of inserts with varying sizes and shapes, tailored to meet specific industry needs. When selecting tungsten inserts, it’s essential to consider factors such as application requirements, environmental conditions, and the desired lifespan of the insert to ensure optimal performance.

When selecting the right tungsten inserts for your specific needs, it’s essential to start by assessing the particular requirements of your application. Tungsten inserts are favored for their durability and high density, often used in various industries ranging from manufacturing to fishing. Understanding the environment in which the inserts will be used can significantly influence your choice. For instance, if the inserts will be exposed to extreme temperatures or corrosive substances, opting for inserts that provide enhanced resistance and stability could be critical.

Tips: Consider the shape and size that will best serve your intended use. For many applications, a well-designed geometry enhances performance. A recent industry report highlighted that the shape of tungsten inserts can affect their effectiveness by up to 30%, making it a vital factor in your decision-making process.

Additionally, review the physical properties of the tungsten being utilized, such as hardness and tensile strength. Data reveals that tungsten alloys can improve wear resistance by nearly 40% compared to standard materials. This enhances longevity and lowers replacement costs over time. Understanding your specific needs from the start will ensure that you select tungsten inserts that not only meet but exceed your operational requirements.

When selecting tungsten inserts, it's crucial to consider various key factors that can significantly impact performance and longevity. One of the primary considerations is the hardness and density of the tungsten material. Tungsten inserts typically range from 9.3 to 19.3 grams per cubic centimeter in density, with higher density options offering enhanced durability and resistance to wear. According to a report by the International Tungsten Industry Association, inserts with a density above 17 grams per cubic centimeter provide better performance in high-stress applications, such as mining and drilling, where the risk of wear and fracture is elevated.

Another essential factor is the specific application for which the tungsten inserts will be used. Different operations, such as machining, aerospace, and oil drilling, have unique requirements that call for tailored insert designs. For example, inserts with specialized geometries and coatings can optimize cutting efficiency and surface finish, while some applications may benefit from inserts that prioritize thermal conductivity. The material's composition, as reported by industry analysts, suggests that tungsten carbide inserts, particularly those with cobalt or nickel bonding agents, enhance toughness and reduce the likelihood of chipping or cracking under high-pressure scenarios.

Lastly, thickness and shape play significant roles in the insert selection process and can directly affect the operational capabilities of the equipment in which they are used. Inserts that are too thin may wear out quickly, whereas overly thick inserts might lead to increased resistance and reduced speed during operations. Ensuring the correct balance between thickness and performance is essential for maximizing both productivity and the insert's lifespan, ultimately leading to lower operational costs and enhanced efficiency in industrial applications.

When selecting tungsten inserts, it’s essential to compare the various types available on the market to make an informed decision tailored to your specific applications. Tungsten inserts primarily fall into categories based on shape and intended use, such as flat, cylindrical, and shaped profiles. A recent industry report by Research and Markets indicates that the global tungsten inserts market is expected to grow significantly, driven by the increasing demand in sectors like oil and gas, automotive, and mining. Each type of insert has unique advantages; for instance, flat inserts offer a larger surface area for stability in high-pressure applications, while cylindrical inserts are favored for their ease of insertion in drilling operations.

Furthermore, the selection can also be influenced by material properties, such as density and hardness. Tungsten is known for its exceptional hardness, with a Vickers hardness rating of approximately 1000 HV, making it superior to other materials like carbide. A study from the American Society for Metals has shown that the right choice of tungsten insert can increase productivity by as much as 30% in machining processes. Understanding the specific attributes of each insert type—such as wear resistance, thermal conductivity, and compatibility with various cutting tools—can drastically affect the outcome of your projects, ensuring efficiency and longevity in demanding environments.

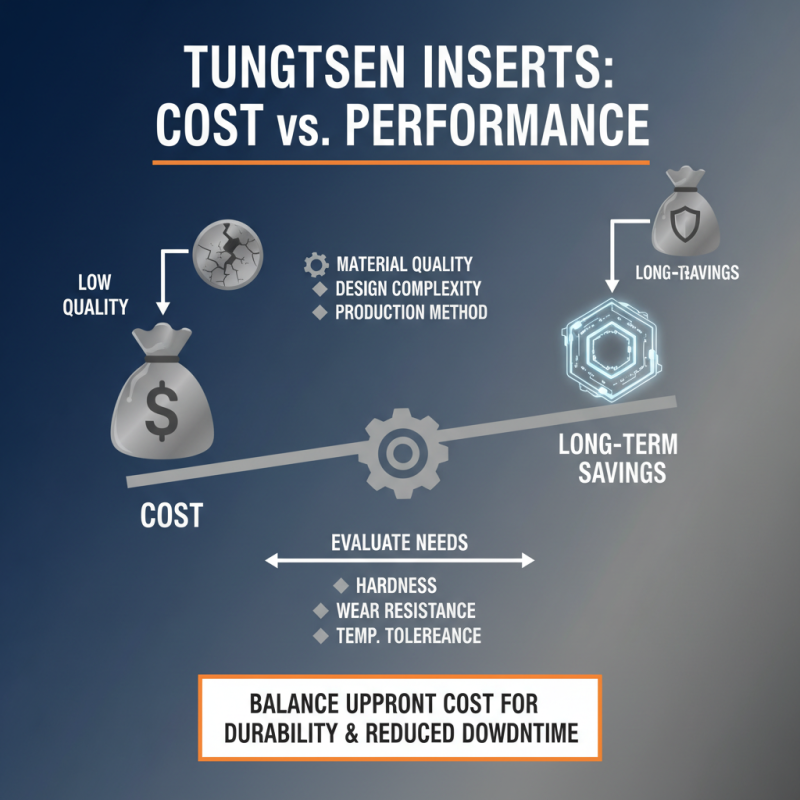

When selecting tungsten inserts, the balance between cost and performance is crucial. Tungsten inserts are widely recognized for their durability and effectiveness in various applications, including manufacturing and machining. However, the cost of these inserts can vary significantly based on factors such as material quality, design complexity, and production methods. It's essential to evaluate what specific performance characteristics you require—such as hardness, wear resistance, or temperature tolerance—and how these relate to the cost of the inserts. Investing in higher-quality tungsten inserts might seem more expensive upfront, but it can result in lower long-term operational costs due to improved durability and reduced downtime.

To make a well-informed decision, consider conducting a cost-benefit analysis of different tungsten inserts. Assess the performance metrics that matter most to your operations and align them with the cost of each option. For instance, if high wear resistance is essential for your application, opting for inserts that excel in this area—even at a higher price—could potentially save you money on replacements and maintenance over time. Additionally, examination of the insert's performance in real-world conditions is vital; sometimes, cheaper options can result in higher overall costs if they do not meet the required performance standards. Thus, a strategic approach to evaluating cost versus performance can lead to more efficient and cost-effective selections in tungsten inserts.