Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

In industries that demand precision and durability, Tungsten Carbide Tubes stand out. According to a market report by Allied Market Research, the global tungsten carbide market is projected to reach $29.42 billion by 2026. This growth is largely driven by the increasing application of Tungsten Carbide Tubes in fields such as mining, oil and gas, and manufacturing. Their inherent toughness makes them suitable for high-stress environments.

The unique properties of Tungsten Carbide Tubes include exceptional hardness and corrosion resistance. These tubes can withstand intense pressure and temperature, reducing downtime in operations. Furthermore, their lightweight nature offers an advantage in transportation and installation. Yet, it's crucial to recognize that despite these benefits, improper handling can lead to issues.

Not all Tungsten Carbide Tubes meet the same standards. Variability in quality exists among manufacturers. This inconsistency can affect performance, leading to failures that are frustrating and costly. Adopting a critical view on sourcing and usage helps maintain operational efficiency. Understanding these factors can guide industries in making informed decisions when investing in Tungsten Carbide Tubes.

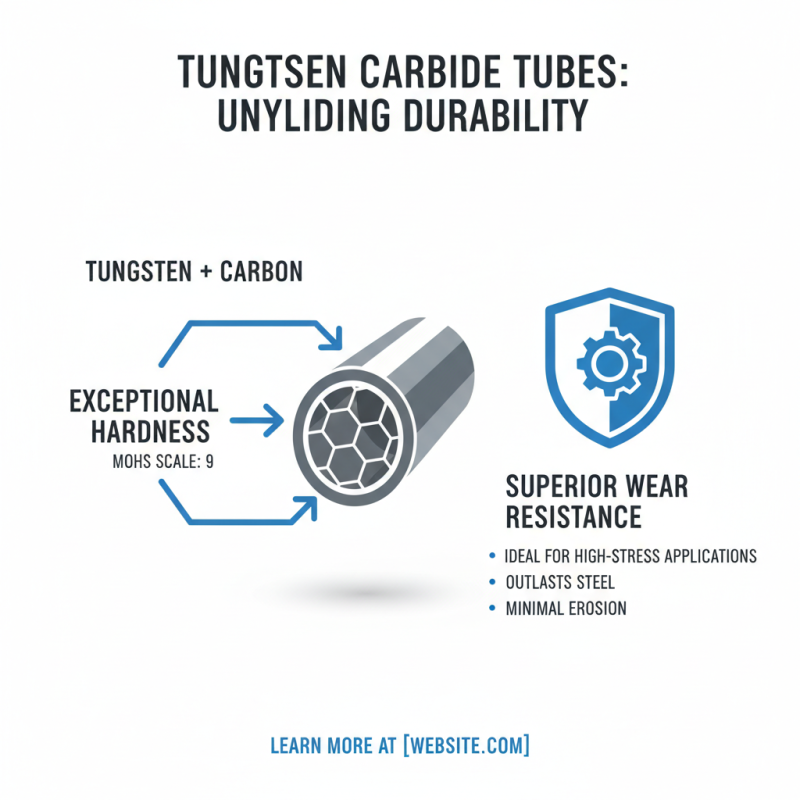

Tungsten carbide tubes are renowned for their exceptional durability and wear resistance. Made from tungsten and carbon, these tubes exhibit remarkable hardness, often surpassing steel. According to a recent industry report, tungsten carbide ranks 9 on the Mohs scale of mineral hardness. This characteristic makes it ideal for applications where resistance to wear and tear is crucial.

The tubes also have a high melting point of 5,200°F, ensuring stability under extreme temperatures. This trait is particularly important in industries like oil and gas and aerospace. Industries report up to a 30% increase in efficiency when using tungsten carbide over traditional materials. However, despite these advantages, some users face challenges with machining and fabrication. The tubes can be brittle if not handled properly, leading to waste and rework.

Their corrosion resistance is another defining feature. Tungsten carbide does not easily corrode, providing longevity in harsh environments. Yet, manufacturers need to ensure proper coatings or treatments to enhance this property for specific applications. The performance consistently highlights the need for careful material selection and application engineering. Understanding these characteristics can lead to better decision-making in material choice.

Tungsten carbide tubes are known for their remarkable durability and wear resistance. This makes them ideal for various applications, from industrial machinery to automotive parts. The enhanced hardness of tungsten carbide minimizes wear over time, reducing the need for frequent replacements. This aspect can save both money and downtime for businesses.

When using tungsten carbide tubes, consider maintenance. Regular inspections can prevent unexpected failures. Look for signs of wear or chipping early on. It’s essential to clean the tubes regularly to avoid material buildup that can lead to performance issues.

Another tip is to pair tungsten carbide tubes with compatible materials. Mismatched materials can lead to stress concentrations, which may cause premature failure. Investing in quality fittings can extend the life of these tubes. Reflection on these aspects can help optimize the benefits of using tungsten carbide effectively.

| Benefit | Description |

|---|---|

| Enhanced Durability | Tungsten carbide tubes are highly resistant to wear and tear, extending their lifespan significantly compared to other materials. |

| High Temperature Resistance | These tubes can withstand extreme temperatures without losing integrity, making them suitable for harsh environments. |

| Corrosion Resistance | Tungsten carbide's composition allows it to resist oxidation and chemical corrosion, enhancing its usability in various applications. |

| Precision Engineering | These tubes can be manufactured to precise dimensions, ensuring high levels of accuracy for industrial applications. |

| Cost-Effectiveness | While the initial investment may be higher, the long-term savings in maintenance and replacement costs render tungsten carbide tubes highly cost-effective. |

Tungsten carbide tubes are widely used across various industries due to their unique properties. They are known for their hardness and resistance to wear. This makes them ideal for applications in mining, oil drilling, and manufacturing. Companies use these tubes to improve efficiency and reduce downtime in operations.

In the aerospace industry, tungsten carbide tubes play a critical role. They are often used in components that require high durability under extreme conditions. The ability to withstand high temperatures and pressures makes them valuable. However, the production process can be challenging. Achieving the right dimensions and qualities requires precision and expertise.

The automotive sector also benefits from these tubes. They are used in engines and exhaust systems, providing strength and longevity. Nevertheless, the cost of tungsten carbide can be a concern. Some companies struggle with budget constraints while trying to incorporate these high-quality materials. Finding the right balance between cost and performance is essential for success.

Tungsten carbide tubes stand out for their cost-efficiency and longevity. These tubes are made from a unique composite that combines tungsten and carbon. This combination results in a material that is extremely hard and durable. Because they resist wear and deformation, they can last significantly longer than other materials. This longevity translates into fewer replacements and lower maintenance costs, making them a smart investment for various industries.

The initial cost of tungsten carbide tubes might be higher than alternatives. However, the long-term savings often outweigh this upfront expense. Businesses find that the extended lifespan of these tubes reduces downtime. For example, in manufacturing, less frequent replacements mean more consistent operations. It's essential to consider this balance when evaluating options. The durability does create a perception of sturdiness, yet improper handling can still lead to fractures.

It's crucial to reflect on the application needs when selecting tungsten carbide tubes. Over-reliance on their strength might result in overlooking regular maintenance. Understanding the trade-offs is key. The emphasis on long-lasting materials shouldn't overshadow the importance of proper usage. Choosing tungsten carbide requires careful evaluation of operational environments and potential risks.

Tungsten carbide tubes bring significant environmental advantages in manufacturing. These tubes are durable and often last longer than alternatives. This longevity reduces the frequency of replacements. Consequently, fewer materials are needed over time, which lowers resource consumption. Manufacturing processes also generate less waste when using longer-lasting materials.

Moreover, tungsten carbide can often be recycled. At the end of its life cycle, it returns to the supply chain. This feature minimizes landfill waste and promotes sustainability. However, recycling processes need improvement. They are not always straightforward, and many facilities lack the necessary infrastructure.

Choosing tungsten carbide tubes may also lead to energy savings. They often require less energy during production compared to other materials. This reduction in energy usage contributes to lower greenhouse gas emissions. But, more research is needed to optimize their production process. It's crucial to analyze the full environmental impact. This includes extraction, manufacturing, and end-of-life management. Addressing these challenges is essential for maximizing environmental benefits.