Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

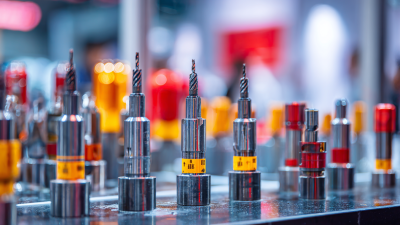

In the ever-evolving landscape of precision machining, the importance of selecting the right tools cannot be overstated. As we look ahead to 2025, the focus on optimizing performance through innovative technologies becomes paramount. Among the myriad of tools available, Dth Bits stand out as essential equipment for those seeking enhanced precision and efficiency in drilling operations. This article delves into the top five Dth Bits that promise to revolutionize performance and accuracy in various applications.

As industries advance, the demand for tools that not only meet but exceed existing standards continues to grow. The Dth Bits highlighted in this guide are engineered with cutting-edge designs and materials, ensuring that they deliver superior performance even in the most challenging conditions. From construction to mining, the right Dth Bits can make all the difference, leading to faster completion times and improved operational outcomes.

Join us as we explore the features and benefits of these top five Dth Bits, equipping you with the knowledge to make informed decisions that will ultimately enhance your workflows and drive success in your projects. Whether you are a seasoned professional or a newcomer to the field, understanding the impact of these tools is essential for achieving excellence in precision drilling.

Understanding Down-the-Hole (DTH) bits is crucial for achieving enhanced performance and precision in drilling applications, particularly in the mining sector. DTH bits are specifically designed to improve efficiency and accuracy while penetrating hard rock formations. According to recent market analyses, the global mining drill bits market was valued at approximately USD 1.88 billion in 2024, with projections indicating growth to USD 2.67 billion by 2032. This upward trend underscores the increasing reliance on specialized drilling equipment to meet the demands of modern excavation processes.

The importance of DTH bits extends beyond mere performance metrics; they play a vital role in worker safety and operational flexibility. For instance, when CNC machining heavy components, like a 45kg piece, utilizing optimized DTH bits can significantly enhance precision, thereby minimizing potential hazards associated with incorrect drilling techniques. Additionally, advancements in design and materials, such as the latest PowerCarbide grade DTH bits, showcase the industry's commitment to extending service life and improving dust control measures during operations, further reinforcing safety protocols in challenging environments. As the mining and drilling sectors continue to evolve, sophisticated tools like DTH bits remain at the forefront of driving efficiency, safety, and superior performance.

This chart illustrates the performance and precision ratings of the top five DTH bits available in 2023 based on factors such as drilling speed, durability, and overall effectiveness.

In 2023, the drilling industry is witnessing significant advancements with the introduction of top-performance DTH (Down-The-Hole) bits that enhance drilling efficiency and precision. The best DTH bits are designed with cutting-edge features that cater specifically to the diverse demands of drilling operations. One key feature is the use of advanced materials, such as tungsten carbide, which significantly increases the tool life. Reports indicate that with high-quality DTH bits, driller productivity can soar by up to 30%, showcasing their vital role in modern drilling applications.

Another important feature is the innovative bit design, which optimizes hydraulic performance, ensuring effective removal of cuttings and reducing the risk of stuck bits. Enhanced flow dynamics contribute to improved penetration rates, with studies showing that well-designed DTH bits can outperform traditional counterparts by nearly 15% in hard rock formations. These performance metrics underscore the need for operators to invest in superior DTH bits to stay competitive in an evolving market, where operational efficiency directly correlates with profitability and project timelines.

When selecting the right DTH (Down the Hole) bit for specific drilling applications, a comparative analysis of various types can significantly impact performance and precision. According to a recent report by Global Market Insights, the DTH drilling market is projected to exceed USD 6 billion by 2023, indicating a substantial increase in demand for optimized drilling solutions. Key factors such as soil conditions, rock hardness, and required penetration rates play a crucial role in determining the most suitable DTH bit.

In examining the leading types of DTH bits, such as the cross and button bits, it’s essential to understand their unique advantages. Button bits, known for their durability and efficiency in hard rock applications, can enhance penetration rates by up to 40% compared to traditional bits, as reported by the Society for Mining, Metallurgy & Exploration. Conversely, cross bits, while less efficient in extremely hard conditions, excel in softer ground and minimize wear on the equipment, making them preferable for specific geological environments. Each type presents distinct benefits, allowing operators to choose based on their specific drilling environment and performance needs.

In 2023, the evolving landscape of drilling technology has highlighted the significance of DTH bits (Down-The-Hole bits) in enhancing drilling performance and precision. Recent reports indicate that advanced materials and designs, such as polycrystalline diamond compact (PDC) and thermally stable PDC bits, have led to a 20% increase in penetration rates while reducing overall drilling costs by up to 15%. These innovations are particularly crucial for industries such as mining and oil extraction, where operational efficiency directly impacts profitability.

Implementing cutting-edge technologies, including vibration damping systems and improved fluid dynamics, allows for better management of drilling conditions. According to the International Association of Drilling Contractors, leveraging these technologies can significantly minimize downtime and enhance bit life by approaching double the performance of traditional bits.

Tips for selecting the right DTH bit include assessing the geology of the drilling site, opting for bits with replaceable cutters for versatile usage, and regularly monitoring bit wear to optimize performance. Furthermore, staying informed about the latest advancements in bit technology can give operators a competitive edge, ensuring they maximize both precision and effectiveness in their drilling operations.

When it comes to enhancing the performance and precision of DTH bits in 2023, maintenance plays a crucial role in ensuring their longevity. Regular inspections should be part of your routine management plan. Look for wear and tear, particularly on the bit's face and cutting edges. If you notice any degradation, it may be time to consider either reconditioning or replacing the bit. Keeping a close watch can prevent unnecessary downtime and costs.

Another vital maintenance tip is to ensure proper cleaning after each use. Accumulated debris can affect the bit's performance and lead to premature wear. A simple rinse with water or an appropriate cleaning solution can make a significant difference. Moreover, applying a protective oil can help prevent rust and corrosion, facilitating better operation during subsequent drilling sessions.

Lastly, always adhere to the manufacturer's recommendations regarding operating parameters. Overexerting a DTH bit can seriously impact its performance and lifespan. Properly calibrating the air pressure and flow rates according to the specific type of bit you're using will not only enhance efficiency but also prolong the bit’s operational life. Taking these steps will help maintain your DTH bits in optimal condition throughout 2023.