Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

Cemented carbide is a composite material known for its exceptional hardness, wear resistance, and strength, making it a cornerstone in various industrial applications. As we look towards 2025, the landscape of cemented carbide applications is poised for transformative innovations driven by advancements in materials science and engineering. This evolution is not only enhancing traditional manufacturing processes but also paving the way for groundbreaking uses in sectors such as aerospace, automotive, and toolmaking.

In the coming years, we can expect to see significant trends emerge in the development and application of cemented carbide, influenced by emerging technologies and environmental considerations. These trends will encompass the optimization of existing applications, the introduction of new formulations, and the integration of smart manufacturing techniques. The focus on sustainability will also play a crucial role, pushing industries to adopt greener practices while maintaining the performance standards that cemented carbide has long been recognized for. As we delve into the top trends shaping the future of cemented carbide, we will explore the intersection of innovation, efficiency, and environmental responsibility that will define this vital material's role in modern manufacturing.

The production of cemented carbide is evolving rapidly, driven by emerging technologies that enhance efficiency and performance. One significant advancement is the integration of additive manufacturing techniques, which allows for the creation of complex geometries and tailored properties. This process not only reduces material waste but also enables the production of components that were previously impossible to manufacture using traditional methods. As industries seek lighter and more durable materials, the role of additive manufacturing in cemented carbide production becomes increasingly vital.

Furthermore, innovations in nanotechnology are reshaping the way cemented carbides are formulated. By manipulating materials at the nanoscale, manufacturers can improve the toughness and wear resistance of cemented carbides, leading to products with superior performance in demanding applications. This new approach not only enhances the material properties but also opens pathways for creating customized solutions that meet specific industrial needs. The convergence of these technologies marks a pivotal shift in cemented carbide production processes, setting the stage for future advancements and broader applications across various sectors.

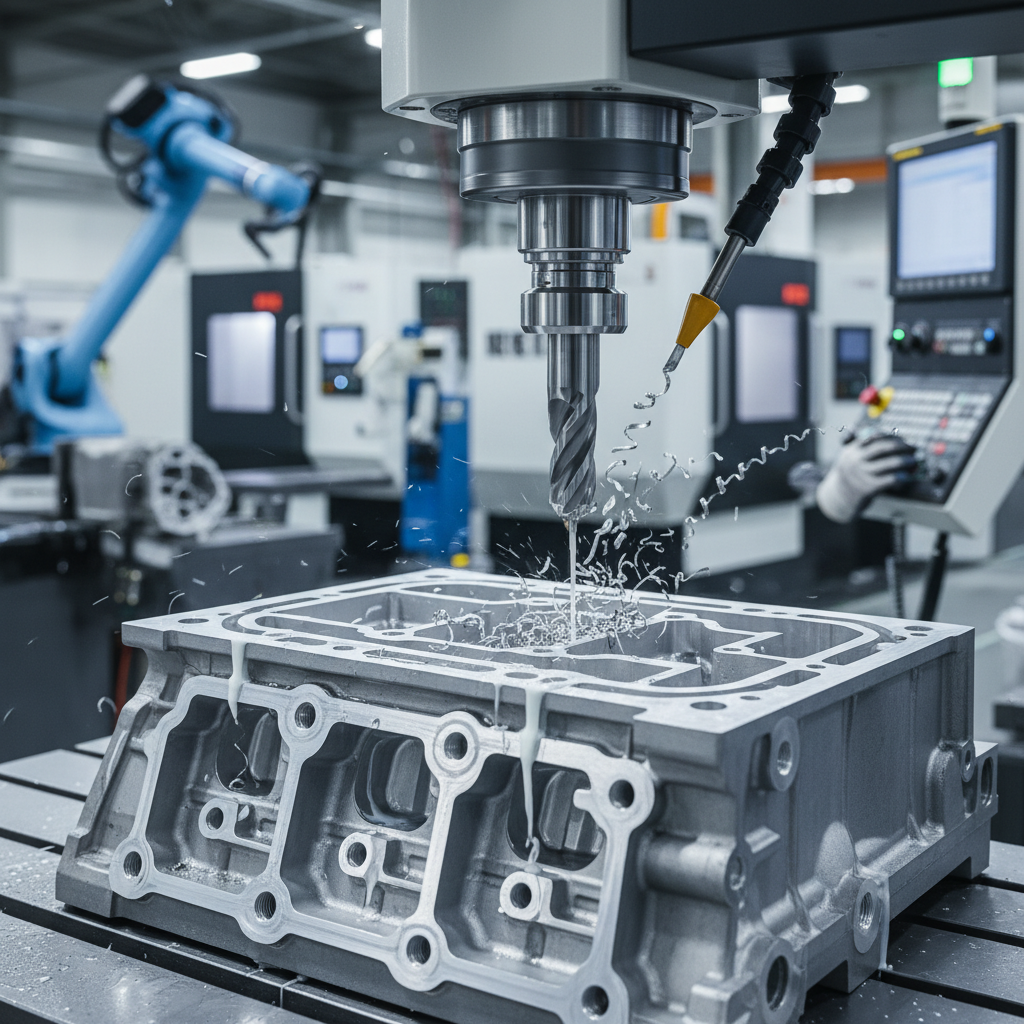

Cemented carbide, known for its exceptional hardness and durability, is paving the way for innovative applications across various manufacturing industries. In the automotive sector, for instance, cemented carbide tools are increasingly utilized for precision cutting and machining operations. These tools not only enhance the quality of finished components but also significantly reduce machining time, thereby improving overall productivity. The ability to withstand high temperatures and wear makes cemented carbide ideal for producing intricate parts in high-performance vehicles.

Moreover, the aerospace industry is tapping into the advantages of cemented carbide in the development of lightweight and resilient components. With the push for more fuel-efficient aircraft, engineers are integrating cemented carbide materials in turbine engines and other critical areas where strength and low weight are paramount. Additionally, innovations in coating techniques and surface treatments are further expanding its capabilities, allowing for enhanced performance and longevity in challenging environments.

As these applications continue to evolve, cemented carbide remains at the forefront of manufacturing innovation, driving efficiency and performance in various industrial fields.

The cemented carbide industry is witnessing a significant shift towards sustainability, driven by both regulatory pressures and market demand. According to a report by MarketsandMarkets, the global cemented carbide market is expected to reach USD 24.07 billion by 2025, growing at a CAGR of 5.9%. This growth is coupled with a rising emphasis on recycling and reusing materials. Innovative manufacturers are developing processes to reclaim carbide scraps, which could potentially divert millions of tons of waste from landfills. Recent studies indicate that up to 50% of carbide can be recycled, thus reducing the need for virgin materials and minimizing the overall environmental impact.

Moreover, advancements in material science are enabling the development of more sustainable formulations of cemented carbides. Research conducted by the International Journal of Refractory Metals and Hard Materials highlights that new grades of carbide can be tailored to enhance durability while using less cobalt, a non-renewable resource. As eco-consciousness continues to grow among consumers and industries alike, the adoption of sustainable practices within the cemented carbide sector is not just beneficial but essential for the future. Embracing these trends will not only improve the ecological footprint of carbide products but also present new business opportunities as manufacturers innovate towards greener solutions.

| Trend | Description | Sustainability Impact | Recycling Innovations |

|---|---|---|---|

| Increased Use of Recycled Materials | Adoption of recycled carbide to reduce raw material usage. | Reduces environmental impact by minimizing virgin material extraction. | Technologies for reclaiming and reusing carbide scrap. |

| Advancements in Manufacturing Processes | Improvement of additive manufacturing techniques for carbide tools. | More efficient use of materials leads to lower carbon emissions. | Additive methods enable better material recovery post-production. |

| Eco-friendly Coatings | Introduction of biodegradable and safer surface coatings for tools. | Helps in reducing toxic waste in manufacturing and disposal. | Enhanced recyclability of coated products through eco-friendly materials. |

| Digitalization and Smart Manufacturing | Implementation of IoT and AI for optimizing production efficiency. | Leads to reduced energy consumption and waste generation. | Data-driven processes can improve sorting and recycling rates. |

| Circular Economy Initiatives | Strategies to create closed-loop systems for carbide products. | Promotes longevity of materials and reduces waste. | Involves take-back systems for recycling carbide tools. |

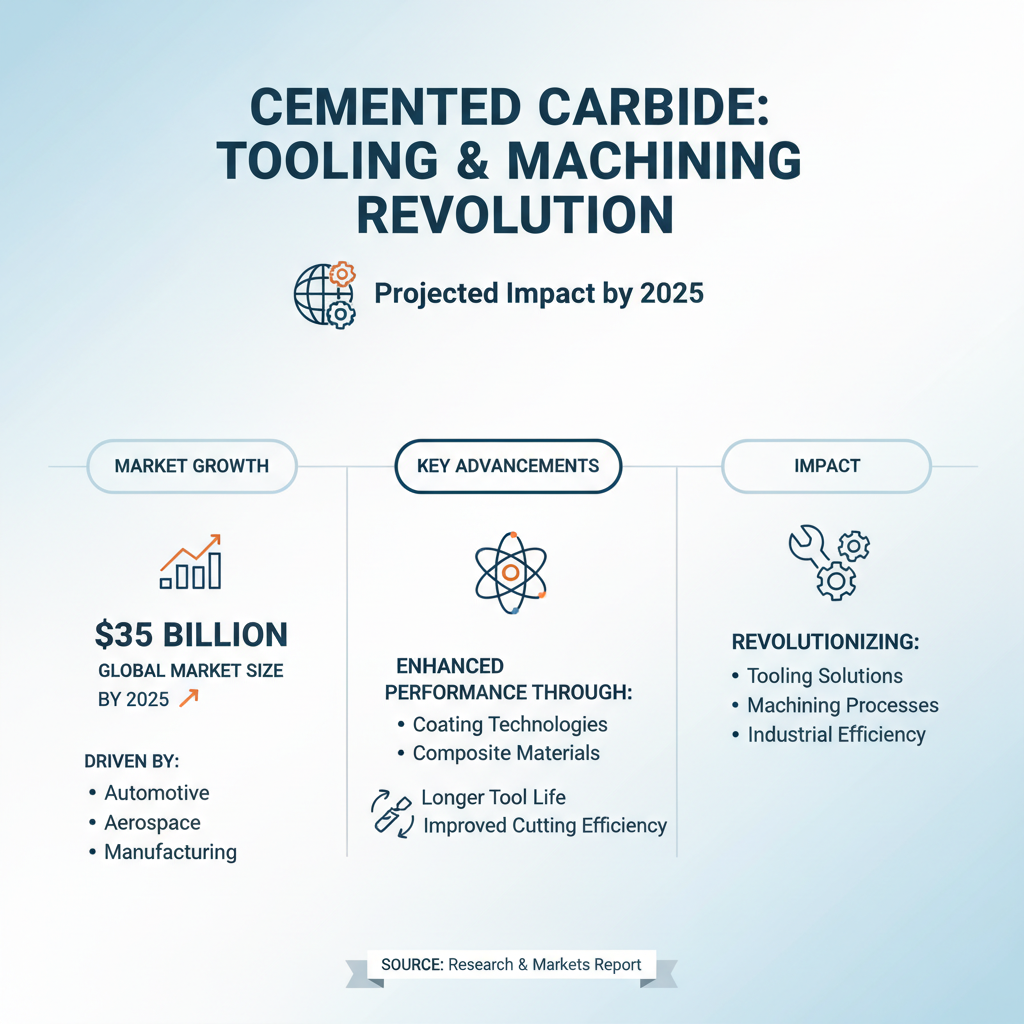

Cemented carbide materials, known for their hardness and wear resistance, are set to revolutionize the tooling and machining solutions landscape by 2025. According to the latest market report by Research and Markets, the global cemented carbide market is projected to reach $35 billion by 2025, driven by increasing demands in various sectors such as automotive, aerospace, and manufacturing. The evolution of cemented carbide tooling is expected to focus on enhancing performance metrics through innovations in coating technologies and composite materials, enabling longer tool life and improved cutting efficiency.

Future developments will likely emphasize smart manufacturing techniques, integrating advanced machining processes with automated systems. For instance, Industry 4.0 initiatives are prompting manufacturers to adopt real-time monitoring technologies, which can optimize tool performance and reduce downtime. A study from the International Journal of Advanced Manufacturing Technology highlights that the implementation of predictive analytics can enhance tool life by up to 30%, making it a significant area of investment. As the industry braces for these changes, manufacturers that embrace these innovations in cemented carbide applications will be at the forefront of machining excellence, propelling productivity and efficiency to new heights.

The cemented carbide market is poised for significant growth, driven by its increasing application across various industries, from automotive to aerospace. According to a recent report by Research and Markets, the global cemented carbide market is expected to reach USD 20 billion by 2025, reflecting a compound annual growth rate (CAGR) of approximately 6.5%. This growth underscores the material's pivotal role in enhancing cutting tools and wear-resistant components, ultimately improving operational efficiency across sectors.

However, the adoption of cemented carbide is not without its challenges. One major hurdle is the high cost of raw materials, specifically tungsten, which has seen price fluctuations in recent years due to supply chain constraints. Additionally, the environmental impact of mining and processing tungsten poses sustainability challenges for manufacturers and end-users alike. A report by Allied Market Research highlights that around 40% of companies are seeking alternative materials or recycling methods to mitigate these concerns, emphasizing the need for innovation in raw material sourcing and production processes. As market dynamics evolve, addressing these challenges will be essential for the continued growth of cemented carbide applications.