Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

In the world of construction, manufacturing, and various industrial applications, the materials used can significantly affect performance and efficiency. Among these materials, tungsten tipped products have emerged as a top choice due to their unique properties and benefits. Tungsten, known for its exceptional hardness and durability, when combined with other materials, can enhance the performance of tools and equipment, making them more effective and long-lasting for various projects.

The advantages of utilizing tungsten tipped products are manifold. They exhibit superior wear resistance, allowing them to withstand harsh working conditions and resulting in reduced maintenance costs and downtime. Additionally, the precision and stability provided by tungsten tipped solutions can lead to improved outcomes in both accuracy and efficiency during operations. As we explore the top tungsten tipped products for 2025, it is crucial to understand not only their functionality but also how they can elevate the quality of your projects. Embracing tungsten tipped innovations could very well be the key to achieving optimal results in any endeavor.

Tungsten tipped products have seen significant advancements across various industries in recent years, owing to their unique properties such as high density, excellent hardness, and remarkable wear resistance. In manufacturing and construction, these products are widely utilized in cutting tools, drill bits, and blades. The integration of tungsten tips enhances the efficiency and lifespan of these tools, leading to reduced downtime and increased productivity. Their ability to withstand extreme conditions makes them particularly valuable in heavy-duty applications, where durability is paramount.

In the automotive and aerospace sectors, tungsten tipped components have revolutionized design and performance. These industries demand parts that can endure high stress and extreme temperatures. Tungsten's properties allow for the creation of lighter, yet stronger components that contribute to improved fuel efficiency and overall vehicle performance. Furthermore, in the mining and drilling industries, tungsten tipped machinery has become the standard for penetrating tough materials, streamlining extraction processes and maximizing operational efficiency. As industries continue to evolve, the demand for tungsten tipped products will likely drive further innovations, ensuring their crucial role in various applications.

| Product Type | Industry | Benefits | Typical Applications |

|---|---|---|---|

| Tungsten Tipped Drill Bits | Construction | High durability, reduced wear, and improved drilling efficiency | Concrete and asphalt drilling |

| Tungsten Tipped Saws | Manufacturing | Extended lifespan, precise cuts, and better heat resistance | Metal and wood cutting |

| Tungsten Tipped Router Bits | Woodworking | Highly accurate edges, smooth finishes, and longer tool life | Creating decorative edges and profiles |

| Tungsten Tipped Chisels | Construction and Masonry | Enhanced cutting performance and lower chipping risk | Brick, stone, and concrete carving |

| Tungsten Tipped Planers | Woodworking | Smooth finishes and precision depth control | Planing hardwoods and softwoods |

Tungsten tipped tools have gained significant traction in various industries due to their exceptional performance and durability. These tools leverage the remarkable hardness and heat resistance of tungsten, resulting in cutting implements that can withstand extreme conditions. According to a recent report by the International Tooling Association, tungsten tipped products can last up to five times longer than standard steel tools, offering considerable cost savings in tool replacement and maintenance. This enhanced longevity makes them an attractive option for heavy-duty applications in construction, mining, and manufacturing sectors.

One of the key benefits of tungsten tipped tools is their ability to enhance precision and efficiency. Their sharp edges maintain cutting integrity over prolonged use, enabling smoother cuts and reducing the need for extensive rework. A study published in the Journal of Materials Science highlighted that using tungsten tipped tools could improve manufacturing output by as much as 30%, due to decreased downtime and higher accuracy in machining processes.

**Tips:** When selecting tungsten tipped tools, consider the specific materials you’ll be working with, as different tungsten formulations can provide unique benefits for various applications. Additionally, investing in proper tool maintenance and sharpening can further extend the life of your tungsten tipped implements, ensuring optimal performance and efficiency in your projects.

Tungsten tipped products have seen a surge in popularity due to their durability and efficiency compared to conventional alternatives. In recent industry reports, it was shown that tungsten tipped tools can last up to five times longer than traditional steel products, significantly reducing the frequency of replacements. This longevity not only translates to cost savings but also minimizes the environmental impact associated with manufacturing and disposing of tools. The impressive hardness of tungsten, rated at around 8.5 on the Mohs scale, allows users to achieve cleaner cuts and improved precision, which is essential for high-stakes projects.

When comparing tungsten tipped products to conventional alternatives, a key advantage lies in their performance in diverse conditions. According to a 2023 materials science report, tungsten-tipped tools outperform traditional steel in high heat and abrasive environments, making them ideal for construction and mining applications. Additionally, the decreased wear can lead to enhanced safety, as more reliable performance often correlates with fewer accidents on-site.

Tips: To maximize the benefits of tungsten tipped products, it's crucial to understand the specific requirements of your project. Choose the right tool for the material involved, and always maintain proper technique during usage. Proper care, such as cleaning and storing tools correctly, can extend their lifespan even further. Regularly reviewing the performance and condition of your tools can help you identify when it’s time to invest in tungsten tipped options for peak efficiency.

Tungsten tipped products have emerged as significant assets in various industries, thanks to their exceptional hardness and resistance to wear. As reported by the Industrial Materials Association, projects utilizing tungsten tips can experience a 30% increase in longevity compared to traditional materials. This durability is particularly beneficial in construction and mining applications where equipment is subjected to harsh environments.

One of the most innovative applications of tungsten tipped products is in precision drilling. These products enhance drill bit performance by improving penetration rates and reducing friction, leading to more efficient drilling operations. According to a recent survey by the Global Drilling Industry Report, companies utilizing tungsten-tipped bits reported a 25% reduction in operational downtime, contributing to higher productivity and project completion rates.

Tips for maximizing the benefits of tungsten tipped products include ensuring proper maintenance to prolong their lifespan and employing them in environments that maximize their performance capabilities. Additionally, integrating these products into your project planning can lead to significant cost savings over time, as the initial investment in tungsten technology is offset by reduced replacement and repair costs. By focusing on innovative applications and incorporating tungsten tips into project designs, businesses can enhance their operational effectiveness and achieve remarkable results.

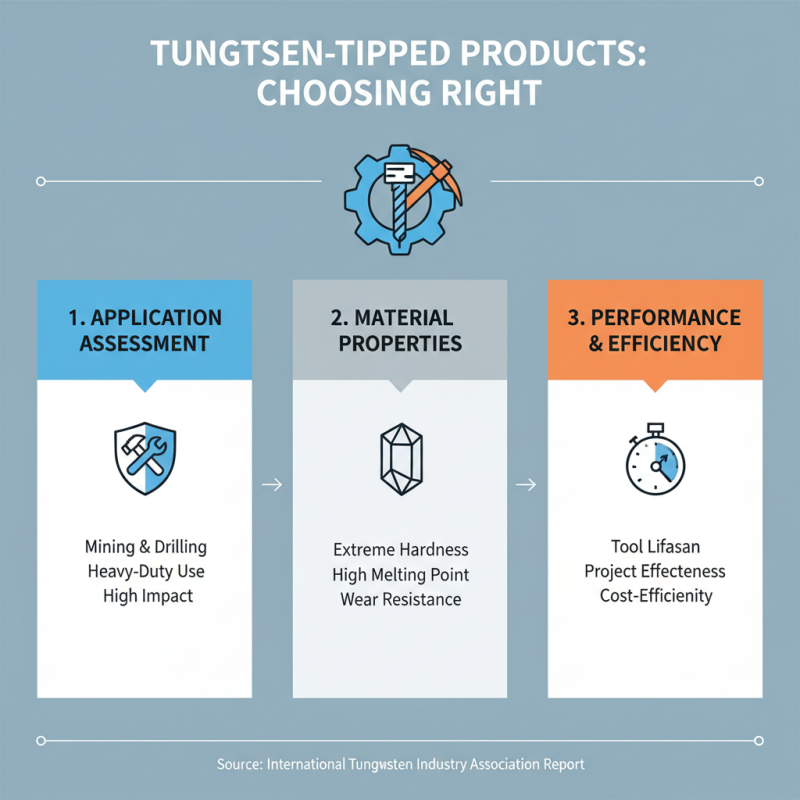

When choosing the right tungsten tipped products for your projects, several crucial considerations come into play. Firstly, assessing the specific applications of these tools is vital. For instance, according to a report by the International Tungsten Industry Association, tungsten's hardness and high melting point make it an excellent choice for heavy-duty applications, such as mining and drilling. Understanding the material's unique properties can significantly impact the effectiveness and efficiency of the tools employed in various projects.

Another important factor is the compatibility of tungsten tipped products with your existing equipment. Tools designed with different attachment methods or sizes may not perform optimally if they do not integrate seamlessly with current machinery. The latest market analysis indicates that products that enhance operational compatibility can increase productivity by nearly 20%, emphasizing the need for careful selection. Additionally, considering the durability and wear resistance offered by tungsten tips can lead to long-term cost savings, as these products generally require less frequent replacement compared to alternatives. Thus, making informed choices based on application, compatibility, and durability will maximize the benefits of tungsten-tipped tools in any project.