Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

Tungsten tipped products have revolutionized various industries with their durability and performance. According to industry expert Dr. Emily Carter, “Tungsten tipped tools provide unmatched precision and longevity.” This statement highlights the growing importance of tungsten tipped options in the market.

Many professionals rely on tungsten tipped products for their effectiveness. These tools excel in tough environments, withstanding wear and tear better than standard alternatives. However, not every product lives up to the hype. Some may fall short in performance or reliability.

Choosing the right tungsten tipped items requires careful consideration. It's critical to evaluate each product's capabilities and limitations. Despite their advantages, users must remain vigilant. Many options exist, and not all will meet your specific needs. The quest for the best tungsten tipped products calls for both exploration and skepticism.

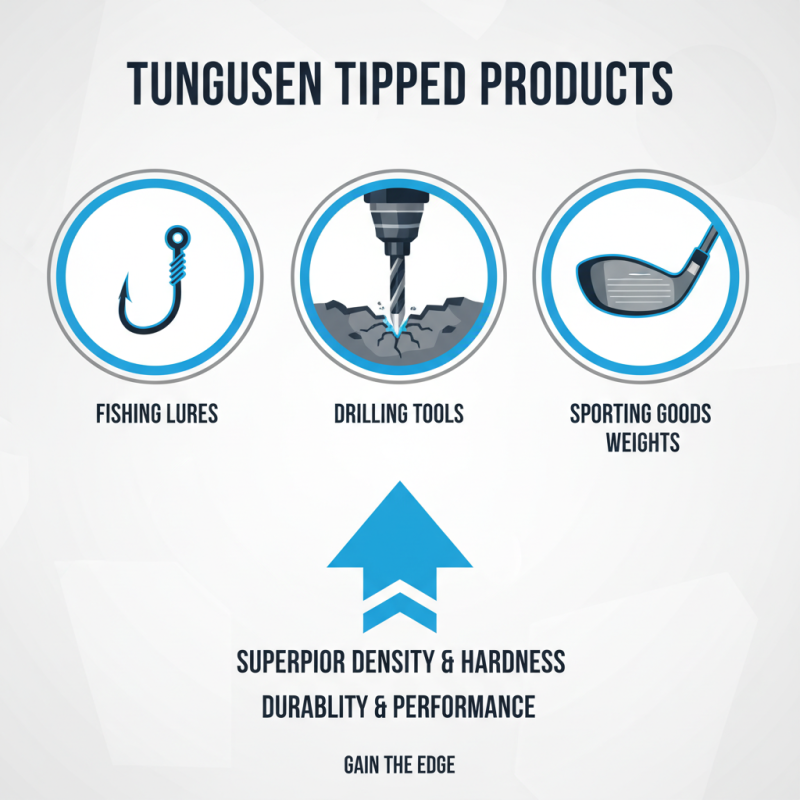

Tungsten tipped products are gaining popularity for various applications. Their superior density and hardness make them ideal for tasks where durability is crucial. Common uses include fishing lures, drilling tools, and even weights for sporting goods. They provide stability and enhance performance, making them highly sought after.

When selecting tungsten tipped products, consider the specific application. Not all products are created equal. Some may not provide the expected performance. For example, fishing lures may not swim well if the design is flawed. It's important to match the weight and shape to your needs.

TIPS: Always check customer reviews. They often reveal insights into real-world performance. Additionally, trying different weights can reveal what works best in various conditions. Don't settle on the first product you find. Experimentation can lead to better outcomes.

Tungsten tipping is a cutting-edge technology widely recognized for enhancing product durability and performance. Tungsten is known for its high density and strength, making it an ideal material for tips on various tools and equipment. Recent industry reports indicate that products with tungsten tipping outperform standard offerings by up to 30% in wear resistance. This translates to fewer replacements and reduced costs in the long run.

The composition of tungsten-tipped products often involves a blend of tungsten carbide and other materials. This combination harnesses the rigidity of tungsten while allowing some flexibility. Interestingly, the production process for these tips is intricate. It requires precision engineering to ensure optimal adhesion of tungsten to the base material. Even minor flaws in this process can impact performance significantly.

Moreover, innovative uses of tungsten tipping extend beyond traditional tools. In the fishing industry, for instance, tungsten-tipped lures have gained popularity. They offer better penetration and balance in water, proving more effective for anglers. However, not all tungsten tipping is equal. Some cheaper alternatives may not deliver the promised performance. Users must carefully assess quality when choosing tungsten-tipped products.

Tungsten tipped products are increasingly utilized in manufacturing due to their exceptional durability and performance. The construction sector, for instance, employs tungsten tipped tools for drill bits and cutting tools. Reports indicate that these tools can last up to five times longer than standard steel tools. This longevity reduces downtime and increases overall efficiency in the production process.

Tungsten's high density and hardness allow for greater precision in manufacturing applications. This precision is critical in industries like aerospace, where even the smallest deviation can lead to serious safety issues. Moreover, the automotive sector benefits from tungsten tipped components that enhance cutting speeds and precision. A recent survey found that manufacturers report up to a 30% increase in productivity when using tungsten tipped products.

Tips: When considering tungsten tipped tools, ensure that they suit your specific application. It's crucial to evaluate the cost versus the longevity of these products. Sometimes, the upfront cost may seem high, but the long-term savings are significant. Additionally, regular maintenance is key; dull tools can negate the advantages of tungsten tips. Always think critically about how these tools fit into your wider manufacturing process.

Tungsten tips are gaining attention for their exceptional durability and precision. They withstand extreme conditions, making them ideal for various applications. This resilience translates into longer-lasting performance. Many users notice fewer replacements, saving both time and money in the long run.

The precision of tungsten tips enhances efficiency. Their weight allows for better control and accuracy. Whether in fishing or hunting, every detail counts. Users report improved experiences when using tungsten-tipped products, feeling more confident in their choices. Yet, not all tungsten tips are created equal. Some may not deliver the promised performance.

When considering tungsten tips, assess your specific needs. Not everyone may require the added weight or durability. It's important to reflect on what works best for you. Testing different options can be worthwhile. The benefits can be significant, but finding the right fit is crucial for achieving desired results.

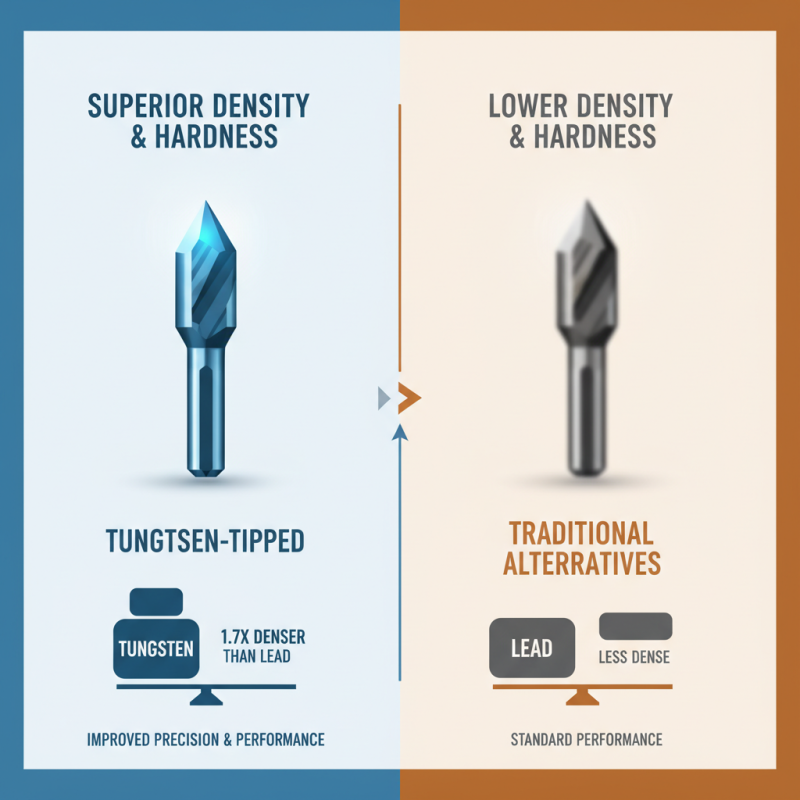

When comparing tungsten tipped products with traditional alternatives, several factors stand out. Tungsten boasts superior density and hardness. According to recent industry reports, tungsten can be nearly 1.7 times denser than lead. This density leads to improved performance, especially in applications requiring precision.

In contrast, traditional materials often struggle with wear and tear. They may require frequent replacement, leading to higher costs over time. Tungsten’s durability helps reduce long-term expenses. It excels in extreme conditions, making it a reliable choice. However, it can be more expensive upfront, which some buyers might find challenging.

Tip: Always evaluate the total cost of ownership. Higher initial costs might pay off in better performance and longevity.

Moreover, tungsten’s eco-friendly profile is appealing. Unlike some traditional products, it doesn’t release harmful substances. This makes it a safer choice for both users and the environment. Yet, users must ensure they have proper recycling methods available, as this material can still pose disposal challenges.

Tip: Consider your specific needs before choosing between tungsten and traditional products. Each option has its pros and cons, ultimately depending on application requirements.

This article explores the top five tungsten tipped products, highlighting their applications and advantages across various industries. Tungsten tipping is a technology that enhances the durability and precision of tools and components, making them more efficient in manufacturing processes. The piece delves into the key applications of tungsten tipped products, demonstrating how they significantly outperform traditional alternatives in terms of longevity and effectiveness.

Additionally, the article presents a comparative analysis, highlighting the benefits of tungsten tips in enhancing performance metrics such as wear resistance and accuracy. As the market for tungsten tipped products continues to grow, projections for 2023 and beyond indicate a rising demand driven by advancements in technology and manufacturing practices. Overall, the exploration of tungsten tipped products underscores their pivotal role in modern industrial applications.