Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

In the realm of precision engineering, the emergence of Tungsten Blanks has revolutionized manufacturing processes and material applications. These dense, durable, and highly malleable materials have garnered attention for their remarkable properties, making them indispensable in various industries, including aerospace, automotive, and tool making. Tungsten Blanks offer a unique combination of high density and superior strength, enabling the creation of intricate designs and components that demand exacting specifications.

As engineers and manufacturers increasingly seek materials that provide both reliability and versatility, Tungsten Blanks stand out as a compelling choice for future innovations. This article explores the science behind Tungsten Blanks, delving into their composition, production methods, and the critical role they play in advancing precision engineering towards unprecedented levels of accuracy and efficiency.

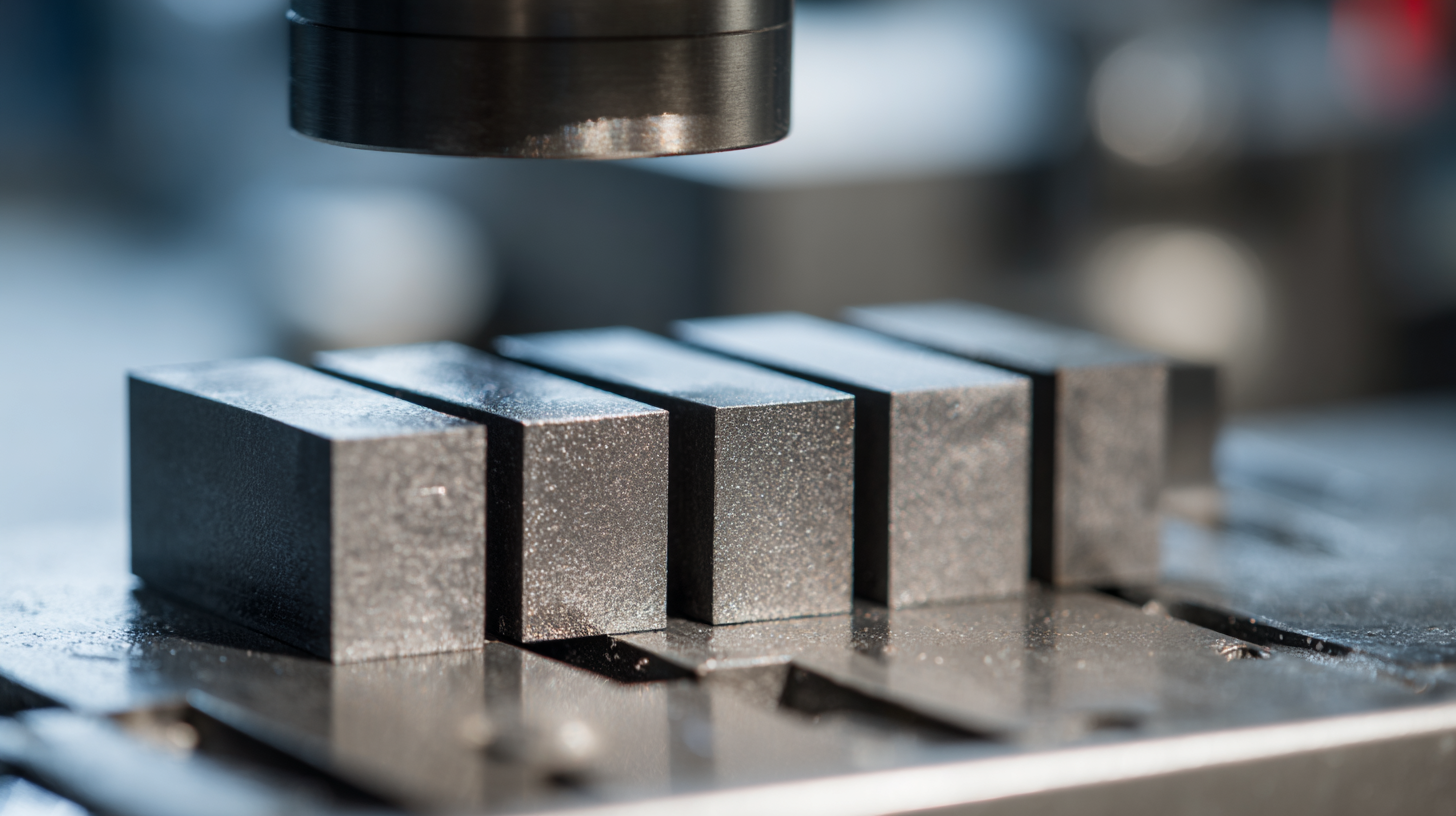

Tungsten blanks are rapidly gaining traction in precision engineering due to their exceptional properties. With a density of approximately 19.3 g/cm³, tungsten is one of the heaviest elements, providing unmatched stability and resilience in demanding applications. Its high melting point of around 3422°C ensures that tungsten can withstand extreme temperatures without losing structural integrity. According to a report by the International Journal of Advanced Manufacturing Technology, components made from tungsten blanks exhibit up to 15% higher performance in wear resistance compared to traditional materials like steel.

In addition to strength, tungsten exhibits excellent machinability when in blank form, allowing engineers to achieve precise tolerances. The versatility of tungsten blanks is highlighted in aerospace and automotive sectors, where their ability to maintain dimensional stability under stress is critical. Recent studies indicate that using tungsten in precision components can enhance lifespan and reduce maintenance costs by about 20%, indicating significant long-term savings for manufacturers.

**Tip:** When selecting tungsten blanks for your engineering projects, ensure that you incorporate advanced machining techniques to maximize their unique properties. Additionally, always consider the specific application requirements to choose the appropriate dimensions and grades of tungsten.

This chart illustrates the unique properties of tungsten blanks, showcasing their density, melting point, thermal conductivity, and Young's modulus. These attributes highlight the advantages of utilizing tungsten in precision engineering applications.

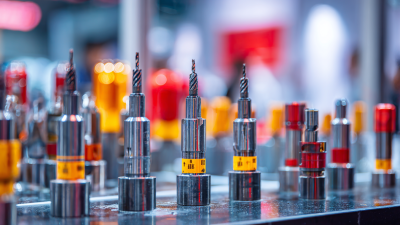

Tungsten blanks are becoming increasingly prominent in precision engineering applications due to their exceptional density and hardness. These attributes enable them to withstand significant wear and tear, making them an ideal choice for high-performance tooling and workholding solutions. According to a report by the International Tooling Association, products made with tungsten blanks show a remarkable increase in longevity, often outperforming traditional materials by up to 30%, which directly impacts overall production efficiency.

At industry events like IMTS 2016, the spotlight on tungsten blanks was evident, as exhibitors showcased innovative tooling solutions that integrate this material. The adoption of tungsten in precision engineering applications is further supported by data from recent market analyses, which predict a sustained growth in demand for tungsten-based products, driven by the aerospace and automotive sectors. As these industries continue to emphasize precision and reliability, the role of tungsten blanks as a fundamental component in engineering processes cannot be overstated.

Tungsten blanks represent a significant advancement in precision engineering, offering a range of benefits over traditional materials. One of the primary advantages of tungsten is its impressive density, which allows for the creation of smaller, more compact components without sacrificing strength. In contrast, traditional materials like steel or aluminum often require larger sizes to achieve similar mechanical properties, potentially increasing the overall weight and size of engineered products. This density also translates to superior stability under varying operating conditions, making tungsten blanks ideal for high-performance applications.

Another key differentiator is tungsten's exceptional resistance to wear and corrosion. Unlike conventional materials that may be prone to degradation over time, tungsten maintains its integrity even in harsh environments. This durability not only extends the lifespan of components but also reduces maintenance costs and downtime in manufacturing processes. Furthermore, tungsten's unique thermal properties allow it to perform effectively at elevated temperatures, which is a limitation often encountered with traditional materials. By leveraging these characteristics, engineers can design more efficient systems that enhance performance and reliability in precision engineering applications.

Tungsten blanks are rapidly gaining traction in precision engineering due to their unique properties and innovative manufacturing techniques. These dense and durable materials boast a tensile strength approximately 1510 megapascals (MPa), making them ideal for applications requiring high performance with minimal wear. Advanced manufacturing processes, such as powder metallurgy, enable the production of tungsten blanks with exceptional tolerances and surface finishes. This method not only reduces wastage but also enhances the reproducibility of complex geometries, which is a critical factor in industries ranging from aerospace to medical devices.

**Tips:** When working with tungsten blanks, it is vital to use precise machining tools that can handle the material’s hardness. Consider employing coated tools designed for metalworking to extend tool life and maintain cutting efficiency.

The continual development of additive manufacturing processes has also shown promise in shaping tungsten blanks. Techniques like selective laser sintering (SLS) allow for the creation of intricate shapes that were previously impossible with traditional methods. According to a recent report by the International Journal of Advanced Manufacturing Technology, the integration of such technologies can lead to a reduction in lead times by up to 30%, providing manufacturers with a substantial competitive edge.

**Tips:** Always conduct thorough thermal analysis during the manufacturing phase to mitigate the challenges posed by tungsten’s high melting point. This will ensure a seamless integration of tungsten blanks into your production workflows.

The demand for tungsten blanks in the precision engineering sector is witnessing a significant surge, driven by their unique properties and versatility. According to a recent report by Market Research Future, the global tungsten market is projected to reach approximately $18 billion by 2027, with tungsten blanks comprising a considerable portion of this growth. This increase is primarily attributed to the material's high density and exceptional resistance to wear and heat, making it ideal for applications in aerospace, automotive, and defense industries.

In addition to traditional uses, emerging technologies are further fueling the need for tungsten blanks. The rise of additive manufacturing and high-performance machining processes necessitates materials that can withstand extreme conditions without compromising precision. Notably, a study from Technavio indicates that the automotive sector's adoption of tungsten-based components is expected to grow at a CAGR of over 5% through 2025. This trend reflects a broader shift towards utilizing advanced materials capable of enhancing durability and efficiency, positioning tungsten blanks as a pivotal element in the future of precision engineering.