Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

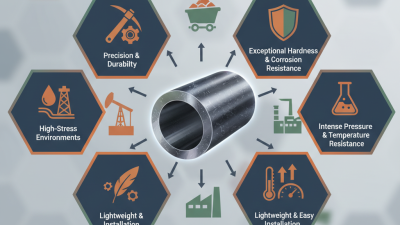

Tungsten Carbide Tube is becoming a preferred choice in various industrial applications. Many industries benefit from its exceptional durability and strength. This robust material can withstand extreme conditions, making it suitable for various tasks.

In manufacturing, the use of Tungsten Carbide Tube enhances efficiency. Machinery components made from this material last longer. They reduce downtime for repairs and replacements, which is crucial for productivity. The trade-off is often higher initial costs. However, the long-term savings are significant.

Not all applications require Tungsten Carbide Tube. Companies must evaluate their needs carefully. Sometimes, alternatives could suffice for less demanding tasks. Yet, when the situation calls for toughness, this material delivers. Choosing it also reflects a commitment to quality and reliability.

Tungsten carbide tubes have gained popularity in various industrial applications. Their hardness and durability make them suitable for extreme conditions. These tubes resist wear and tear, enhancing the longevity of machinery. They are often used in mining, oil and gas, and manufacturing sectors. With such resilience, maintenance costs can be significantly reduced.

One of the standout benefits of tungsten carbide tubes is their temperature resistance. They can withstand high heat without losing strength. This property is essential in processes that involve intense heat, where other materials may fail. However, they are not entirely immune to thermal shock. Adverse temperature changes can still lead to cracking if not properly managed.

Another important aspect is their corrosion resistance. Tungsten carbide effectively minimizes damage from harsh chemical environments. This quality is crucial in industries that handle caustic materials. Despite these advantages, over-reliance on tungsten carbide can lead to neglecting alternative materials. Sometimes, a mixed approach can provide better flexibility and resilience. It's essential to assess specific applications to ensure the best choice is made.

Tungsten carbide is known for its exceptional durability and wear resistance. This makes it an ideal choice for industrial applications. The material can endure extreme conditions that would quickly damage lesser alternatives. For instance, in environments with high friction, tungsten carbide maintains its integrity over time.

Many industries rely on this strength. Mining, machining, and manufacturing benefit significantly. Tools made from tungsten carbide resist scratches and deformation. They can handle abrasive materials without losing effectiveness. This resistance translates to lower maintenance costs and longer service life.

However, the cost of tungsten carbide can be higher than other materials. Some companies hesitate to make the investment. Yet, the long-term savings often outweigh initial expenses. It’s crucial to weigh these factors carefully. Evaluating specific needs is necessary to determine the best fit for each application.

Tungsten carbide tubes are becoming essential in various industries. Their durability makes them ideal for tough environments. Some common applications include mining, oil and gas, and manufacturing.

In mining, these tubes are used for drill bits. They withstand high pressure and extreme wear. This makes them reliable for extracting resources.

In the oil and gas sector, tungsten carbide tubes are crucial for downhole operations. They prevent wear and tear from harsh conditions. These tubes help transport fluids efficiently.

In manufacturing, they are often used in tools and machinery. Their strength enhances performance and reduces downtime. However, the cost may be higher than other materials. This can be a barrier for some businesses.

Agriculture is another area where tungsten carbide tubes play a role. They are used in precision planting tools. The durability helps in maintaining consistent performance. Many industries face challenges when integrating new materials. It's essential to weigh the benefits against the costs. Exploring options will lead to better decisions.

When considering long-term industrial projects, cost-effectiveness is crucial. Tungsten carbide tubes offer exceptional value due to their durability. According to industry reports, tungsten carbide has a lifespan five times longer than standard steel. This longevity translates into fewer replacements and reduced downtime, ultimately saving money.

Investing in tungsten carbide may have higher upfront costs. However, the long-term benefits can significantly offset these initial expenses. Studies reveal that industries using tungsten carbide tubes can reduce operational costs by up to 30% over time. This is especially relevant for machinery exposed to high stress and wear. The wear resistance of tungsten carbide makes it an ideal choice for various applications.

**Tip:** Regularly assess your machinery's performance to determine the best materials for your needs. Analyzing your equipment's wear patterns can help ensure that you choose materials that will last. This consideration will lead to smarter investment decisions in the long run.

When considering materials for industrial applications, tungsten carbide tubes stand out for their impressive durability and performance. Compared to traditional steel, tungsten carbide offers superior hardness. This material can withstand extreme wear and high temperatures, making it ideal for demanding environments. Steel, while strong, can suffer from faster degradation under similar conditions.

[Insert Image Here] Ceramic is another alternative worth mentioning. It can resist heat well but is often brittle. A small impact can cause cracks. In contrast, tungsten carbide combines strength with toughness. It does not easily break under stress, which is vital in most industrial settings. However, it may require careful handling during installation.

It's essential to weigh these factors when making a choice. Cost is always a consideration. Tungsten carbide tubes can be more expensive upfront. Yet, their longevity may justify the expense over time. Decisions should not be made lightly. Reflecting on the specific needs of your application can guide you to the right choice. Sometimes, the best answer isn't the most obvious one.