Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

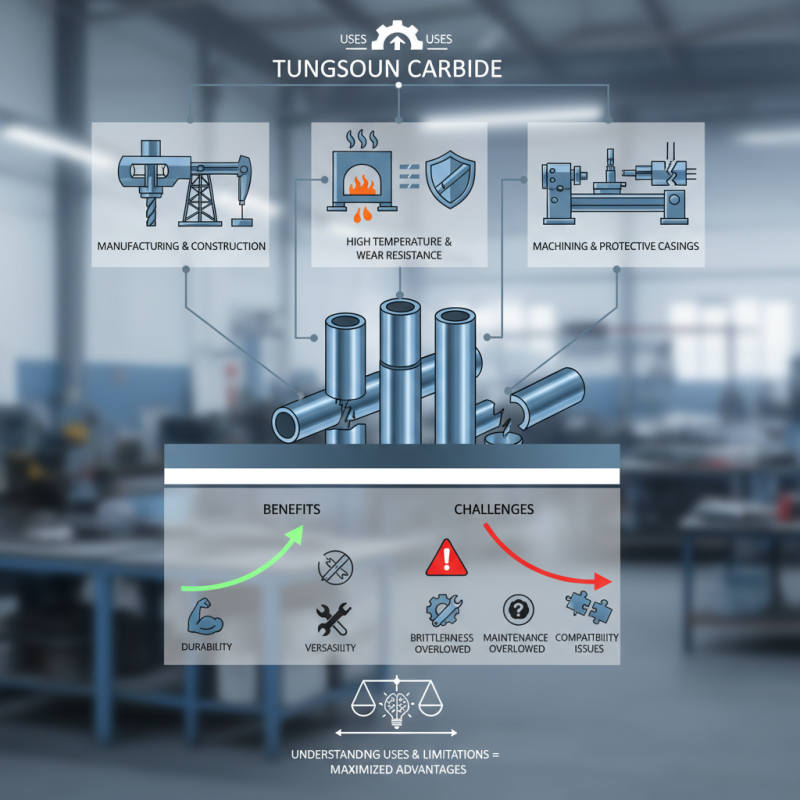

Tungsten Carbide Tube is a remarkable material known for its durability and versatility. This tube is often used in various industries, from manufacturing to construction. Its valuable properties stem from tungsten carbide, a combination of tungsten and carbon that creates a dense, hard substance.

In practical applications, Tungsten Carbide Tubes can withstand high temperatures and resist wear. They are ideal for machining tasks and can serve as protective casings. However, despite their strength, they may require careful handling to avoid fracturing. Users often overlook the need for proper maintenance.

Many industries benefit from this material’s unique qualities. Yet, as with any product, there can be challenges. Awareness of potential issues, such as brittleness or compatibility with specific processes, is essential. Understanding both the uses and limitations of Tungsten Carbide Tubes helps maximize their advantages.

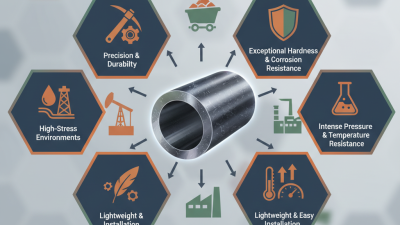

Tungsten carbide tubes are an innovative material shaping many industries today. This compound consists of tungsten and carbon atoms, creating a very hard and heat-resistant structure. Its unique composition allows these tubes to withstand high temperatures and resist wear, making them ideal for various applications.

These tubes find their way into manufacturing, mining, and oil industries. For instance, their durability makes them perfect for drill bits and cutting tools. The ability to resist corrosion adds to their appeal in harsh environments. However, working with tungsten carbide requires precision and care, as it can be challenging to machine.

While tungsten carbide offers many advantages, it is essential to recognize its drawbacks. The material can be brittle, which might cause unexpected failures during heavy usage. Additionally, the cost can be relatively high compared to other materials, prompting companies to weigh their options carefully. Balancing cost and performance is a crucial consideration in its selection.

Tungsten carbide tubes are widely used in various industries due to their strength and durability. These tubes excel in applications involving high wear and tear. For instance, they are commonly found in the mining industry. They help transport minerals effectively while resisting abrasive materials. In this harsh environment, standard tubes often fail. Tungsten carbide proves more reliable, but it’s not a one-size-fits-all solution.

In the oil and gas sector, tungsten carbide tubes serve a critical function. They are used in drilling operations, handling high pressure and temperature. Their ability to withstand corrosive substances is essential for maintaining operational efficiency. However, the cost of tungsten carbide can be high. Some companies weigh the benefits and risks. They might consider alternatives. Nonetheless, when durability is crucial, many firms opt for tungsten carbide solutions.

Another area of application is manufacturing components for machinery. These tubes provide reinforcement for parts under constant stress. While robust, they may require specific machining techniques. The challenge lies in ensuring precision. Not all machine shops have the capabilities. Thus, companies need to evaluate their resources carefully. Tungsten carbide tubes show immense potential, but their implementation demands thoughtful consideration.

Tungsten carbide tubes are gaining popularity due to their unique properties. They offer significant advantages over alternative materials like stainless steel and aluminum. According to recent industry reports, tungsten carbide is about 10 times harder than steel. This hardness translates into a longer lifespan for tubes, making them ideal for heavy-duty applications.

The resistance to wear and corrosion in tungsten carbide is remarkable. Data indicates that these tubes can withstand harsh environments, such as high temperatures and acidic conditions. For example, they can maintain structural integrity in temperatures exceeding 1,000 degrees Celsius. In industries like mining and oil drilling, this durability leads to reduced downtime and lower maintenance costs.

Though tungsten carbide tubes come with a higher upfront cost, the long-term savings often justify the investment. Some engineers find it challenging to work with them due to their brittleness, which can lead to breakage if not handled correctly. This trade-off requires careful consideration. Overall, the performance benefits tend to outweigh the challenges, particularly for applications demanding superior strength and durability.

When it comes to maintaining tungsten carbide tubes, regular checks are essential. Even though they are highly durable, neglect can lead to wear. Inspect for signs of scratches, chips, or cracks. These tiny flaws can affect performance. If you find any, it might be time for repair or replacement.

Cleaning is another key aspect of care. Use a soft cloth and mild soap. Hard brushes can scratch the surface. After cleaning, ensure the tube is completely dry before storage. Moisture can lead to corrosion over time. It’s crucial to store them properly, too. A designated, cushioned space will prevent accidental damage.

While tungsten carbide tubes are resistant, they are not impervious. Some users overlook the need for preventive care. This can result in unexpected failures. Regular maintenance extends their lifespan. It saves time and resources in the long run. Pay attention to the little things; they matter.

Tungsten carbide tubes are widely used across various industries due to their exceptional hardness and wear resistance. This chart illustrates the percentage of usage frequency in different fields such as Industrial Equipment, Aerospace, Medical Devices, Construction, and Electronics, highlighting the versatility and demand for tungsten carbide tubes.

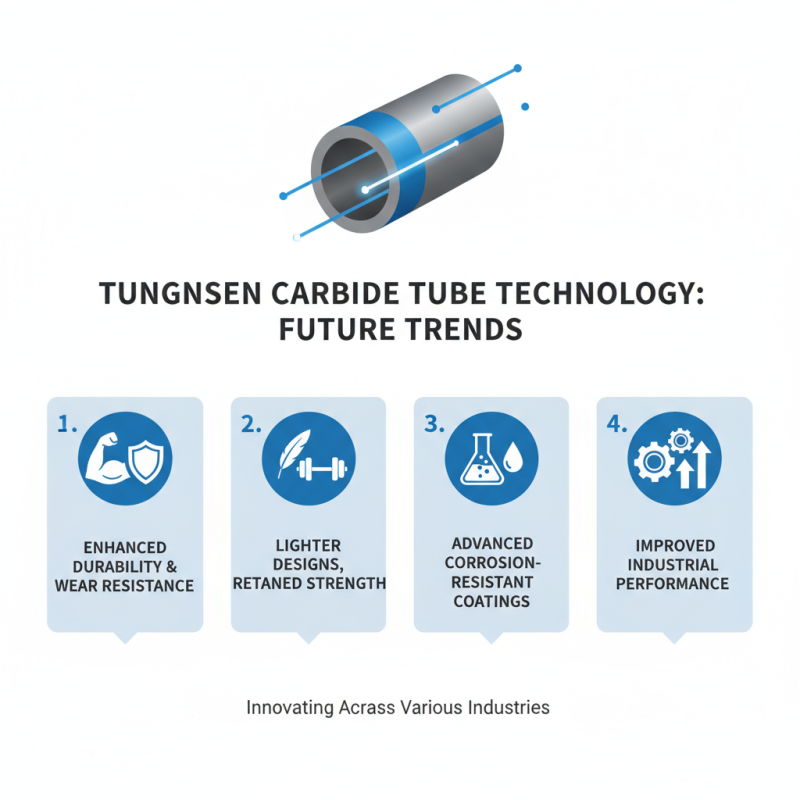

Future trends in tungsten carbide tube technology show exciting prospects. This material is highly durable and resistant to wear. Innovations are pushing for lighter designs while maintaining strength. Manufacturers are exploring advanced coatings that enhance corrosion resistance. These developments may improve performance across various industries.

The growing demand for sustainable practices also influences design choices. Eco-friendly manufacturing methods are gaining attention. This shift could make tungsten carbide more accessible. However, challenges remain in balancing performance with environmental impact. Continuous experimentation will be essential in addressing these issues.

Adoption of tungsten carbide tubes in new applications is on the rise. Areas like aerospace and medical devices are exploring its potential. The need for precision and reliability drives this change. Yet, not all applications may experience immediate benefits. Some industries must carefully assess the cost versus performance ratio. The future is bright, but expectations must be grounded.