Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

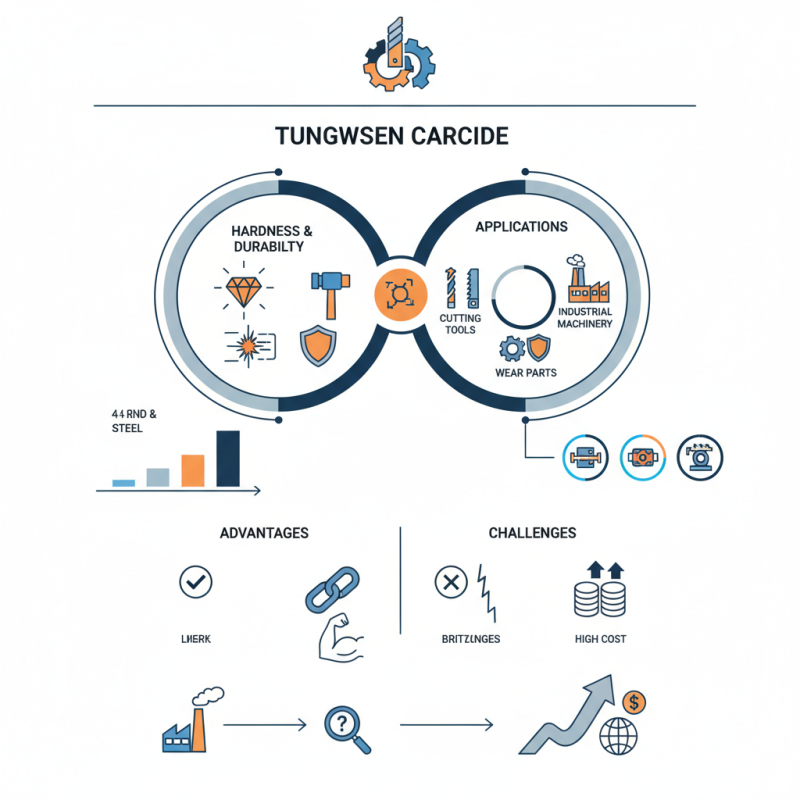

Tungsten Carbide is a remarkable material known for its hardness and durability. According to industry reports, it is more than four times harder than steel. This makes it ideal for various applications, including cutting tools, wear parts, and industrial machinery. In fact, the global tungsten carbide market is projected to reach USD 27 billion by 2026, highlighting its importance across multiple industries.

Despite its advantages, using Tungsten Carbide comes with challenges. For example, while it resists wear effectively, it can be brittle under certain conditions. Also, its high cost compared to other materials may deter some industries. Analyzing these trade-offs is essential for decision-makers in the adoption of Tungsten Carbide technology.

Understanding the best uses and applications of Tungsten Carbide is crucial. Each application has unique requirements that can affect performance and cost. This exploration will shed light on how industries can leverage this material effectively while recognizing the factors that may limit its use.

Tungsten carbide is a compound that consists of tungsten and carbon. This material is known for its exceptional hardness and wear resistance. Its density is also impressive, making it ideal for heavy-duty applications. Tungsten carbide can withstand extremely high temperatures and pressure. These properties make it valuable in various industries, including manufacturing and construction.

When it comes to practical applications, tungsten carbide is often used in tooling. Cutting tools, drills, and inserts made from this material outperform many alternatives. Its toughness allows for intricate shaping and detailing in materials like metal and wood. However, not every project requires tungsten carbide. For softer materials, it may be overkill.

Tips: Consider the specific needs of your project. Tungsten carbide may not be necessary for lighter tasks. Know your material! If you're working with softer components, explore other options. Sometimes, simpler materials yield better results. Be mindful of the cost too. Tungsten carbide can be pricier than alternatives. Always assess if the investment is justified.

Tungsten carbide is a powerful material widely used in industrial machinery and tools. Its incredible hardness and resistance to wear make it ideal for cutting tools, drill bits, and industrial machinery parts. These tools can endure extreme conditions, which boosts production efficiency.

Tips: When selecting tungsten carbide tools, consider the specific application you have in mind. Different grades might be necessary for various tasks. Also, think about the environmental factors. An inappropriate tool choice can lead to premature wear and additional costs.

In manufacturing, tungsten carbide plays a crucial role. It is often used in components like punches and dies. These parts shape materials precisely, ensuring consistent quality. However, there is a learning curve. Not everyone understands the intricacies of these tools. Mistakes can happen, especially if workers lack training.

Tips: Proper training on tool use can mitigate errors. Investing in education is essential for maximizing efficiency. Review your processes regularly to identify areas for improvement. It's easy to overlook small issues, but even minor adjustments can lead to significant gains in productivity.

| Application | Description | Advantages | Industries |

|---|---|---|---|

| Cutting Tools | Used for manufacturing precision cutting tools like drills and mills. | High hardness, wear resistance, and cutting efficiency. | Manufacturing, Aerospace, Automotive |

| Mining Tools | Tungsten carbide is used in drill bits and other mining equipment. | Excellent toughness and resistance to high impact. | Mining, Construction |

| Wear Parts | Components subject to high wear, such as liners and impellers. | Durability and ability to maintain shape under stress. | Manufacturing, Oil and Gas |

| Jewelry | Used in the creation of rings and other jewelry items. | Scratch resistance and hypoallergenic properties. | Jewelry, Fashion |

| Armor | Utilized in armor-piercing ammunition. | High density and hardness for maximum penetration. | Defense, Military |

Tungsten carbide plays a vital role in aerospace applications. It is recognized for its extreme hardness and resistance to wear. This makes it ideal for components subjected to high stress and harsh conditions. Research shows that parts made from tungsten carbide can last 3 to 5 times longer than traditional materials. This longevity translates into significant cost savings for manufacturers.

In aerospace, components like turbine blades and nozzles benefit greatly from tungsten carbide. These parts experience high temperatures and pressures. Tungsten carbide’s stability under such conditions reduces the risk of failure. A report by the Aerospace Materials Consortium noted that using tungsten carbide in turbojet engines improved performance by up to 20%. This is crucial for efficiency in both commercial and military aviation.

However, there are challenges. The manufacturing process of tungsten carbide can be complex and costly. Not all manufacturers have the capability to work with this material effectively. Additionally, tungsten carbide is heavy, which can affect overall aircraft weight. Careful consideration is necessary to balance these factors in practical applications.

Tungsten carbide has gained popularity in jewelry and fashion due to its unique aesthetic appeal. Its bright, polished finish catches the eye, making it a favorite for rings and bracelets. The metal's sleek look complements various styles, from modern to classic. Many appreciate how tungsten carbide can mimic the appearance of precious metals at a more accessible price.

When choosing tungsten carbide jewelry, consider how it weighs in your hands. The substantial feel can be reassuring but may not suit everyone's taste. Opt for pieces with intricate designs to showcase their beauty. These details facilitate a unique expression of style. Remember, though, that personalization can sometimes blend too many elements, leading to a chaotic look.

Tip: Always inspect the quality of the finish. A well-polished piece will have fewer scratches and a longer lifespan. Another tip is to choose styles that reflect your personality. A simple band might resonate more than an overly ornate piece. Balance between flair and subtlety often yields the best results.

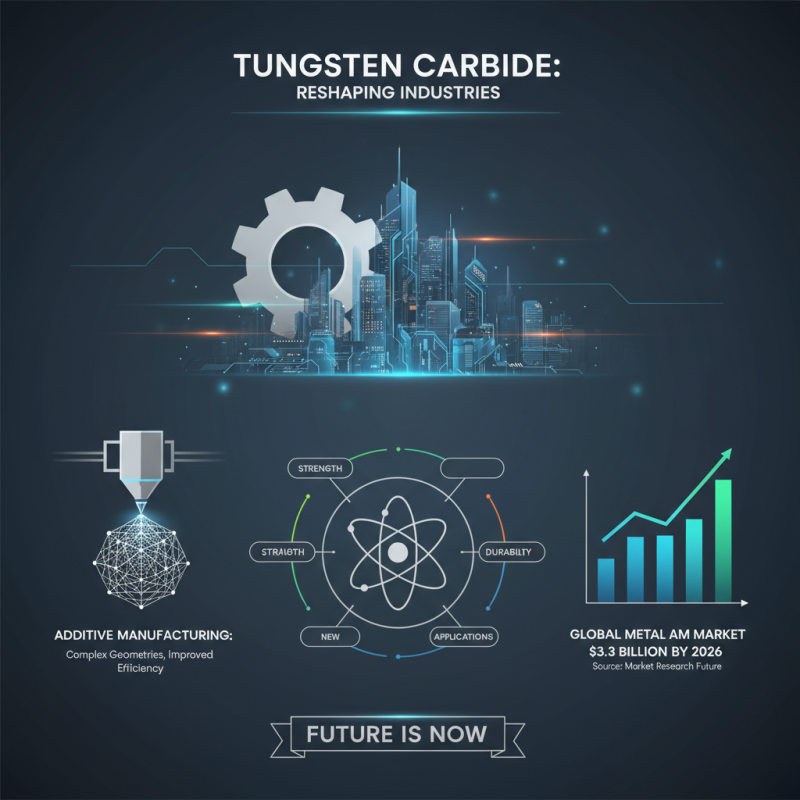

Emerging technologies are reshaping the landscape of tungsten carbide applications. Industries are now exploring its potential in additive manufacturing. This method allows for the creation of complex geometries, improving efficiency. A report from Market Research Future highlights that the global market for additive manufacturing in metal is expected to reach $3.3 billion by 2026. Tungsten carbide plays a crucial role here, providing strength and durability.

In the realm of electronics, tungsten carbide's thermal conductivity is noteworthy. This makes it an ideal candidate for integrated circuits and semiconductor applications. The global semiconductor market is projected to grow to $1 trillion by 2030, driven by the demand for advanced materials. However, challenges remain regarding production costs and scalability. Not all manufacturers can easily adapt to these emerging processes.

Innovative mining technologies also leverage tungsten carbide. Its usage in drill bits significantly increases efficiency and reduces downtime. Reports suggest a 20% increase in productivity with tungsten carbide tools compared to traditional materials. Yet, the environmental impact of mining must be addressed. The industry is under pressure to adopt more sustainable practices, which could slow growth in certain sectors.