Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

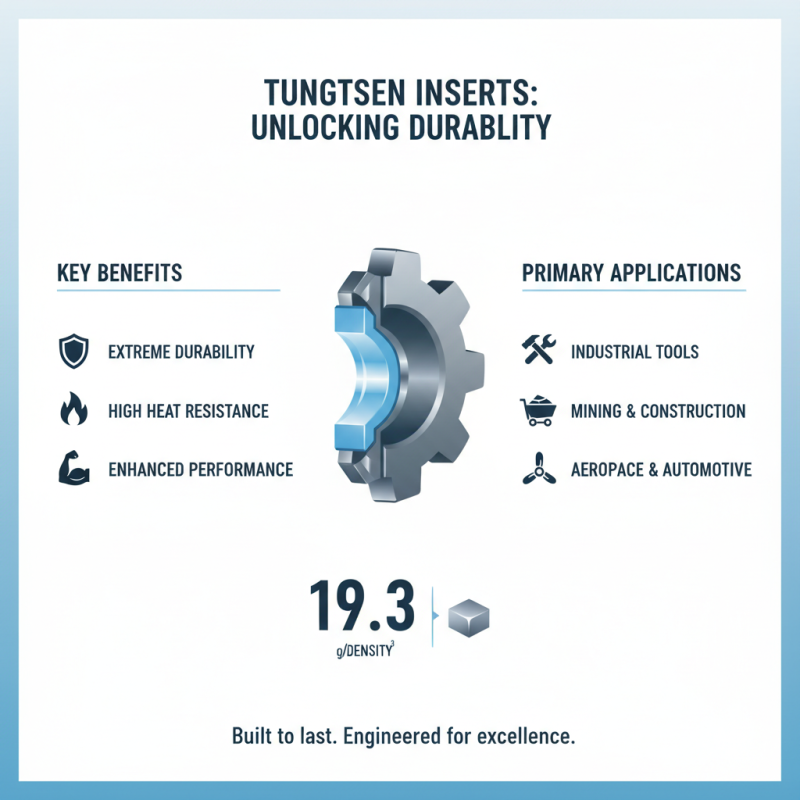

Tungsten Inserts are essential components in many industrial applications. They are known for their strength and durability. These small yet powerful tools enhance the performance of various machines and equipment.

The design of Tungsten Inserts makes them ideal for high-stress conditions. They withstand extreme temperatures and pressure. Many industries rely on these inserts for better efficiency and longevity. Their unique properties allow them to perform in ways that other materials cannot.

However, not all Tungsten Inserts are created equal. Companies often struggle to find the right type for their needs. There can be a learning curve involved in understanding how each insert works. This complexity highlights the need for deeper research. Individuals must consider multiple factors when choosing the right insert.

Tungsten inserts are precision components commonly used in various industries. They are made from tungsten, a dense and durable metal. These inserts serve different purposes, depending on their application. Their weight and toughness make them particularly valuable in high-performance environments.

One notable use of tungsten inserts is in fishing lures. Anglers appreciate their ability to sink quickly and provide better casting distance. They can enhance the effectiveness of a lure by allowing it to mimic the movement of prey. This specificity of function is a key reason many choose tungsten-rated materials over alternatives.

However, the cost of tungsten materials can be a drawback. They are often pricier than other types of inserts. This elevated price may lead some to reconsider if the benefits are worth the expense. It's important to weigh the pros and cons, especially for hobbyists and casual users. Ultimately, understanding tungsten inserts means recognizing both their advantages and challenges.

| Feature | Description |

|---|---|

| Material | Tungsten, known for its high density and melting point. |

| Application | Used in various industries including military, aerospace, and manufacturing. |

| Functionality | Enhances weight and stability of products such as fishing lures, and drilling components. |

| Weight | Often used to add weight without increasing size. |

| Durability | Highly resistant to wear and extreme temperatures. |

| Manufacturing Process | Can be manufactured using sintering or machining methods. |

| Cost | Generally more expensive than other materials due to extraction and processing costs. |

Tungsten inserts are innovative components known for their remarkable density and durability. The primary material, tungsten, is one of the heaviest metals, boasting a density of 19.3 g/cm³. This characteristic makes tungsten inserts ideal for applications demanding weight and stability, such as in drilling and machining operations. Industry reports indicate that tungsten is nearly 1.7 times denser than lead, making it a superior choice for specific industrial applications.

The composition of tungsten inserts often includes varying percentages of cobalt, nickel, and other metals that enhance their hardness and wear resistance. For instance, tungsten carbide, a common form, consists of approximately 80% tungsten and 20% carbon. This combination offers immense hardness, ranking 9 on the Mohs scale. Despite their strength, tungsten inserts can present challenges in processing. Machining them requires specialized tools due to their toughness. Tools tend to wear out faster than expected, leading to increased downtime.

The mechanical properties of tungsten inserts are crucial for their functionality. They exhibit high tensile strength and resistance to deformation under stress. However, the brittleness of tungsten can limit its applications. When subjected to extreme impact, these inserts may fracture. This fragility needs careful consideration in design and usage. Proper implementation can mitigate issues and maximize their benefits in various industrial contexts. Therefore, understanding the intricate balance between composition, properties, and practical applications is essential for optimizing the performance of tungsten inserts.

Tungsten inserts are vital in various industries, enhancing durability and performance. The manufacturing process of these inserts is intricate and requires precision. Tungsten, a dense metal, undergoes multiple steps before becoming an insert.

The raw material starts as tungsten powder. This powder is compacted into molds. The molds shape it into the desired insert form. High pressure ensures that particles bond together. After molding, the inserts are sintered in a furnace. This process involves high heat, which further strengthens the material. Sintering helps remove any porosity, resulting in strong, solid inserts.

Quality control is essential during manufacturing. Each batch needs testing to ensure consistency and durability. Imperfections can arise, making it necessary to evaluate and adjust. The final inserts must meet strict specifications before being used. This rigorous process highlights the importance of precision in creating reliable tungsten inserts.

Tungsten inserts find applications across various industries due to their exceptional density and hardness. In mining, they enhance the durability of drill bits. According to a 2021 report by the Mining Association, using tungsten inserts can extend bit life by up to 40%. This improvement is crucial in reducing operational costs.

In the aerospace sector, tungsten inserts are used in components that withstand extreme temperatures and pressures. They contribute to more efficient fuel usage. An analyst report from Aerospace Innovations indicates that tooling with tungsten materials can decrease maintenance needs by 25%. Such numbers highlight the potential for better performance, yet reliance on these materials can lead to sourcing challenges.

Manufacturing fields also benefit significantly. Tungsten inserts increase efficiency in machining processes. A study from the Fabrication Research Institute stated that their incorporation can reduce cycle times by 15%. However, despite these advantages, some manufacturers struggle to adapt and fully utilize these materials effectively.

Tungsten inserts are gaining popularity in various tools and equipment. They are used to enhance durability and performance. The density of tungsten, about 19.3 g/cm³, makes it ideal for heavy-duty applications. These inserts can withstand high wear and extreme temperatures.

One significant benefit of tungsten inserts is their ability to increase tool life and reduce replacement costs. According to industry reports, tools equipped with tungsten inserts can last up to 50% longer than their standard counterparts. This longevity not only saves money but also minimizes downtime in manufacturing processes. Users report improved precision, which leads to better product quality.

However, tungsten inserts have their challenges. They can be more difficult to machine, requiring specialized equipment. The initial investment is higher compared to traditional materials, which may deter some users. This complexity means that operators must be well-trained to maximize the benefits of tungsten inserts. Balancing cost and efficiency is critical for making the most of these advanced components.