Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

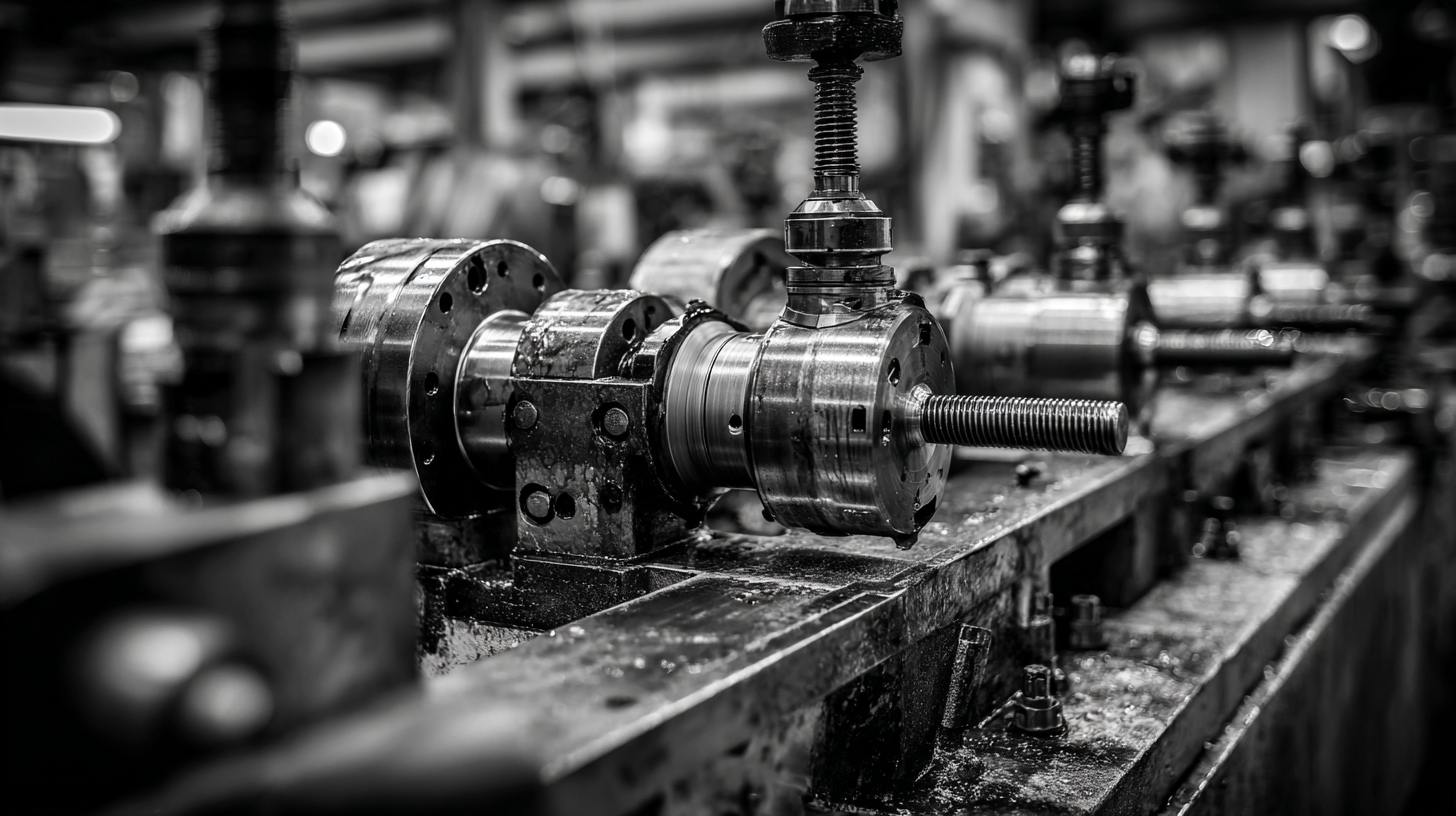

Drilling tungsten is a specialized process that plays a crucial role in various modern industries, particularly in manufacturing and engineering applications. Known for its exceptional hardness and density, tungsten presents unique challenges and requirements when it comes to drilling techniques and tools. Understanding the characteristics of drilling tungsten is essential for professionals seeking to optimize production efficiency and ensure precision in their work.

This blog delves into the intricacies of drilling tungsten, exploring the specific methods and technologies employed, as well as the importance of material properties and tool selection. By examining these factors, we aim to provide insights that will not only enhance comprehension but also improve outcomes for those working with this formidable metal in contemporary industrial settings.

The high melting point of tungsten, which reaches approximately 3,422 degrees Celsius, positions it as an ideal material for drilling applications in modern industries. This exceptional thermal resilience enables tungsten tools to maintain their structural integrity under intense heat generated during the drilling process.

According to a recent report by the International Journal of Advanced Manufacturing Technology, tungsten-based drilling tools exhibit a significant decrease in wear rates compared to traditional materials at elevated temperatures, enhancing their longevity and performance.

The importance of tungsten extends beyond its thermal properties; its density and hardness contribute to superior penetration capabilities. A study from the International Society for Rock Mechanics indicated that tungsten drill bits could increase drilling efficiency by up to 30% in hard rock formations compared to standard high-speed steel drill bits. This efficiency not only improves productivity but also reduces operational costs, making tungsten a preferred choice for energy, mining, and construction sectors. As industry demands grow for more robust drilling solutions, tungsten's unique characteristics will continue to revolutionize drilling technology.

Innovative drilling techniques are transforming the way tungsten is machined in modern industry, allowing for greater efficiency and precision. As tungsten is known for its exceptional hardness and high melting point, traditional drilling methods often struggle to achieve desired outcomes. To address this, engineers are now incorporating advanced technologies such as laser-assisted drilling and high-speed machining. These techniques not only reduce tool wear but also enhance the overall quality of the machined parts, leading to higher productivity rates.

Innovative drilling techniques are transforming the way tungsten is machined in modern industry, allowing for greater efficiency and precision. As tungsten is known for its exceptional hardness and high melting point, traditional drilling methods often struggle to achieve desired outcomes. To address this, engineers are now incorporating advanced technologies such as laser-assisted drilling and high-speed machining. These techniques not only reduce tool wear but also enhance the overall quality of the machined parts, leading to higher productivity rates.

Moreover, the application of specialized drill bit designs, such as polycrystalline diamond (PCD) inserts, has proven effective in penetrating tungsten more effectively. These bespoke tools cater specifically to the unique properties of tungsten, ensuring smoother operations and longer tool life. Coupled with improved cooling methods, such as cryogenic cooling, the risk of thermal damage is minimized, further enhancing the machinability of tungsten. As industries continue to innovate, these modern drilling methods are setting new benchmarks for efficiency and quality in the fabrication of tungsten components.

The tungsten mining industry has become a crucial player in the global economy,

particularly as supply chain dynamics shift. With China imposing new export restrictions, countries and industries

reliant on tungsten are facing significant challenges. This has prompted nations to seek greater autonomy in tungsten

production, exemplified by the reopening of the Sangdong Mine

in South Korea, which boasts one of the largest tungsten reserves worldwide. As firms secure strategic agreements to ensure

supply—a key move given the heightened economic leverage exerted through these trade dynamics—the economic implications

of tungsten mining are becoming increasingly pronounced.

Tips:

The modern industry faces unique challenges when drilling tungsten, a material known for its exceptional hardness and high melting point. Advanced tools have emerged as vital in enhancing the efficiency and precision of tungsten drilling processes. According to a report by the International Journal of Advanced Manufacturing Technology, the use of specialized drill bits, such as carbide-tipped and diamond-coated options, can significantly improve drilling speed and reduce tool wear by up to 30%. These enhancements not only facilitate faster project timelines but also lower operational costs.

Moreover, the integration of computer numerical control (CNC) technology has revolutionized tungsten drilling. A study published by the Journal of Materials Processing Technology highlights that CNC machines can achieve tolerances of ±0.005 mm, which is crucial when precision is paramount. This level of accuracy ensures that components can be manufactured to exact specifications, reducing material waste and subsequent environmental impact. As industries increasingly adopt these advanced technologies, the overall productivity of tungsten drilling processes is expected to rise, making it more viable for various applications, including aerospace and military sectors.

The production and usage of tungsten in modern industry bring significant environmental considerations that cannot be overlooked. Tungsten mining and drilling processes are energy-intensive and often lead to habitat disruption and pollution. As mines operate, they can contaminate local water sources with heavy metals and chemicals, posing risks to both wildlife and human health. Therefore, implementing sustainable mining practices is crucial to minimize the ecological footprint.

Additionally, the lifecycle of tungsten products—ranging from tools to electrical contacts—must also be assessed for environmental impacts. Recycling tungsten can significantly reduce waste and energy consumption associated with new production. By prioritizing the development of closed-loop systems and improving recycling technologies, industries can harness tungsten's properties while adhering to environmental stewardship. Corporate responsibility in tracking and reducing emissions during both production and usage phases is essential in maintaining the balance between industrial demand and environmental health.