Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

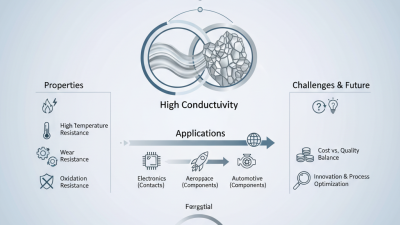

In the realm of electrical applications, the use of Silver Tungsten Alloy has garnered significant attention. Dr. John Thompson, a leading expert in electrical materials, once stated, "Silver Tungsten Alloy bridges the gap between conductivity and durability." This dual capability makes it a sought-after material in various industries.

Silver Tungsten Alloy excels at high temperatures and in environments with rapid switching. For instance, its resistance to arc erosion is crucial for switch contacts. However, the high cost of production often raises questions. Manufacturers must weigh the benefits against the expense of this premium material.

Despite its advantages, some industries still hesitate to adopt Silver Tungsten Alloy. A lack of understanding may contribute to this reluctance. Greater education about its properties and applications is essential. Practical insights can lead to more widespread use, benefiting electrical systems overall. Addressing uncertainties will promote further exploration in future projects.

Silver tungsten alloy is gaining attention in electrical applications due to its unique properties. This alloy combines high electrical conductivity with superior thermal stability, making it ideal for switch contacts and resistors. A report from the International Journal of Electrical Engineering highlighted that silver tungsten can withstand temperatures up to 300 degrees Celsius. Its excellent arc resistance is another significant advantage. In fact, this property extends the lifespan of electrical components.

When considering silver tungsten, it’s beneficial to note its hardness. The alloy boasts a greater hardness than pure silver. This allows it to resist wear during mechanical operation. However, achieving the right balance in alloy composition is crucial. Too much tungsten can compromise conductivity.

Tips: Always consider the application type before selecting the alloy. Conduct tests under real operating conditions. This ensures optimal performance and reliability. Proper handling of the alloy is also vital. Techniques to minimize exposure to moisture can improve longevity. Silver tungsten is not without challenges. The fabrication process requires precision. This can lead to higher costs and potential production delays. Careful consideration is essential to fully leverage its advantages.

This bar chart illustrates the electrical conductivity of Silver Tungsten Alloy in comparison to several other conductive materials commonly used in electrical applications. Silver Tungsten Alloy, recognized for its excellent performance under high temperatures and contact pressures, shows a balanced conductivity characteristic in comparison to pure silver, copper, and aluminum.

Silver tungsten alloy is increasingly popular in electrical applications. This material excels in high-performance scenarios. Its unique properties enhance contact longevity and reliability.

One of the key benefits is its excellent conductivity. The presence of silver improves electrical performance significantly. In environments with high temperatures, silver tungsten remains stable. It resists erosion and wear, minimizing downtime. This durability proves advantageous for various industries, from aerospace to automotive.

However, there are challenges. The production process can be complex and costly. Not all applications may justify this investment. Additionally, handling the material requires care to prevent damage. Despite these issues, the benefits usually outweigh the drawbacks. Silver tungsten alloy continues to be a game-changer in making electrical contacts more effective.

| Application Area | Key Benefit | Typical Use Cases |

|---|---|---|

| Electrical Contacts | High Durability | Relays, Switches |

| High-Voltage Applications | Low Contact Resistance | Circuit Breakers, Power Distribution Systems |

| Automotive | Excellent Heat Conductivity | Starter Contacts, Ignition Systems |

| Telecommunications | Corrosion Resistance | Connectors, Antennas |

| Industrial Equipment | Stable Performance at High Temperatures | Surge Protectors, HVAC Systems |

When it comes to electronics, silver tungsten alloy plays a vital role. This alloy offers excellent electrical conductivity and thermal resilience, making it useful for various applications. The manufacturing processes of this alloy are particularly crucial. These processes often include powder metallurgy and sintering techniques to create the desired shapes and densities.

In powder metallurgy, fine silver tungsten powder is mixed. This mixture is then compacted into molds. Next, it undergoes sintering, where heat is applied to create a solid piece. This method allows for precise control over the alloy's properties. Sometimes, imperfections arise in the compaction stage. These need careful inspection. Adjusting pressure can help improve the density and uniformity of the end product.

**Tips:** Monitor temperature carefully during sintering. Uneven heating can lead to weak points. Additionally, when machining the alloy, use sharp tools. Dull tools can cause chipping or cracking. Always test samples first before mass production to gauge performance.

Silver tungsten alloy plays a crucial role in high-current switching devices. This alloy combines the conductivity of silver with the durability of tungsten. This unique blend allows it to withstand the intense wear and high temperatures often encountered in electrical applications. In fact, it has a melting point of over 3,000°C, making it ideal for extreme conditions.

The demand for silver tungsten in industries such as transportation and energy has surged. Recent reports indicate that the market for these materials is projected to grow by 5% annually. High-current devices, like circuit breakers and contactors, benefit significantly from silver tungsten's performance. For example, they display superior resistance to arc erosion, allowing for longer lifespan and reliability.

However, the use of silver tungsten isn’t without challenges. Higher costs compared to other materials can deter some manufacturers. Additionally, there are concerns regarding the environmental impact of mining tungsten. Companies must consider these factors while weighing the benefits. Overall, silver tungsten remains a key player in high-current applications. Companies should continually assess its integration into their electrical devices for optimal performance and sustainability.

Silver tungsten alloy is a popular choice in electrical applications due to its unique properties. Compared to copper or aluminum, silver tungsten offers higher conductivity. It also boasts superior wear resistance. This makes it ideal for contact points in switches and relays.

However, it's important to note that while silver tungsten is excellent in high-temperature environments, it can be brittle. This brittleness can lead to cracking under extreme stress. Users should assess their specific application requirements carefully.

Tip: Always examine the mechanical properties of materials. Ensure they match the operational demands of your project.

When comparing silver tungsten to other materials, its ability to maintain conductivity under high loads stands out. Materials like gold offer good conductivity too, but they lack the strength that silver tungsten provides.

Tip: When choosing a material, consider both performance and cost. Sometimes, the most expensive option is not the best for your needs.

In summary, understanding the characteristics of silver tungsten alloy can lead to better design choices in electrical applications. Keep in mind the trade-offs when selecting materials for specific uses.