Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

In the evolving landscape of industrial materials, Tungsten Carbide Carbon stands out for its remarkable durability. Dr. Alex Thompson, a leading expert in material science, once stated, "Tungsten Carbide Carbon offers unparalleled strength, but its applications require precision." This insight underscores the significance of understanding this material's unique properties.

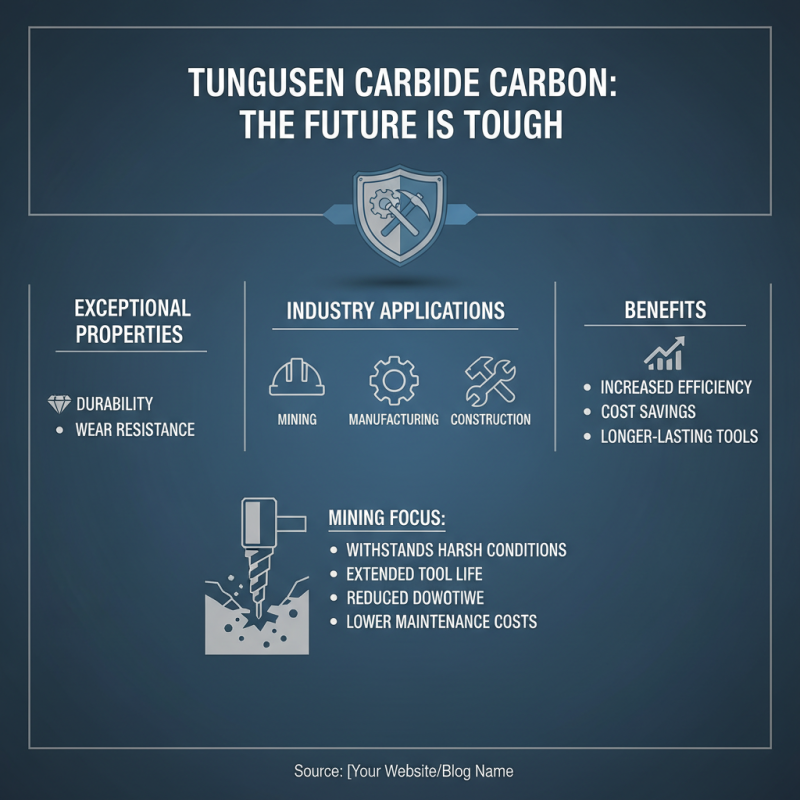

Tungsten Carbide Carbon combines tungsten's toughness with carbon's hardness. The result is a substance that resists wear and strain. Many industries rely on this material, from mining to manufacturing. Yet, its optimal use demands careful consideration of various factors. Improper handling can diminish its effectiveness, leading to costly mistakes.

As more companies adopt Tungsten Carbide Carbon, the need for best practices grows. Understanding how to maximize its potential isn't straightforward. Time and experimentation are key to uncovering innovative applications. This journey isn't without challenges. Issues like tool wear and maintenance are common. A proactive approach is essential to truly harness its benefits.

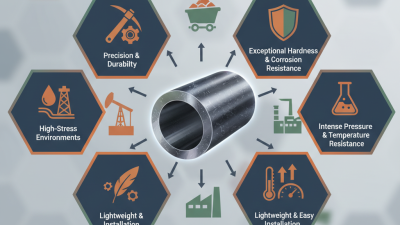

Tungsten carbide carbon is renowned for its impressive properties. This material is exceptionally hard, making it ideal for many applications. It features a remarkable resistance to wear and corrosion. These qualities make it valuable in various industries, from mining to manufacturing.

When using tungsten carbide carbon, the heat treatment process is crucial. This process can enhance its toughness, but it can also introduce brittleness if done incorrectly. Attention to detail during this phase is necessary. Improper treatment may lead to premature failure, which can be avoided by careful monitoring.

Moreover, the joining techniques for tungsten carbide carbon can be complex. Welds can weaken the material if not executed properly. Understanding the welding temperatures and techniques is essential. Every application demands specific considerations, which can be challenging. Learning from these experiences can lead to significant improvements in the future.

Tungsten carbide carbon is increasingly popular across various industries. Its unique properties provide exceptional durability and wear resistance. This material excels in mining, manufacturing, and construction. In mining, its toughness withstands harsh conditions. Mining tools made from tungsten carbide carbon last longer. They reduce downtime and maintenance costs.

In manufacturing, tungsten carbide carbon is often used for cutting tools. These tools offer precision and longevity. The material remains sharp longer than alternatives. Industries working with metal benefit significantly from this. However, tools may chip or wear unevenly at times. Regular inspections are crucial to ensure efficacy.

Construction utilizes tungsten carbide carbon in drill bits and saw blades. These applications require durability and strength. However, improper handling can lead to failures. Users must be trained to avoid damaging the tools. Additionally, the cost may be higher than other materials. Balancing cost and performance is essential in decision-making.

Tungsten carbide carbon is known for its exceptional toughness and wear resistance. To enhance its durability, specific techniques can make a significant difference. One common method is to apply a coating. Coatings protect against oxidation and corrosion. They also improve the material's ability to withstand extreme conditions. This simple step can lead to longer lifespans for various tools and components.

Another technique involves the optimization of the manufacturing process. By adjusting the sintering temperature, manufacturers can achieve better density and uniformity. This change improves the mechanical properties of tungsten carbide carbon. However, not all manufacturers employ these advanced settings. It's essential to assess the production techniques used and their potential impact on durability.

Regular maintenance also plays a crucial role. Inspections and cleaning can prevent wear over time. Neglecting these steps may lead to premature failure. It’s a reminder that while tungsten carbide carbon is robust, it is not invincible. Being proactive with care ensures that its remarkable durability can be fully appreciated.

Tungsten carbide carbon products are renowned for their exceptional durability. However, maintaining their performance requires attention to proper care methods. Regular cleaning is crucial. A gentle detergent combined with warm water is effective in removing contaminants. Avoid harsh chemicals, as they can damage the surface.

Inspection plays a vital role in maintenance. Frequent checks for wear and tear can help identify early signs of degradation. According to industry reports, nearly 30% of premature failures are linked to insufficient maintenance. Addressing small issues promptly can prevent costly replacements down the line.

Storage conditions should not be overlooked. Humidity and temperature fluctuations can affect longevity. Keeping products in dry, temperature-controlled environments is beneficial. Even minor changes can influence the structural integrity of tungsten carbide carbon. Regular education on these practices can lead to better product life. Thus, being proactive in maintenance is essential for maximizing durability.

| Maintenance Practice | Description | Frequency | Benefits |

|---|---|---|---|

| Regular Cleaning | Remove dirt and contaminants from surfaces. | Weekly | Prevents corrosion and wear. |

| Inspections | Check for chips, cracks, or wear on products. | Monthly | Ensures early detection of potential failures. |

| Lubrication | Apply appropriate lubricants to reduce friction. | Bi-monthly | Improves performance and extends lifespan. |

| Restoration | Sharpen or re-coat worn tools and components. | As needed | Maximizes utility and efficiency of products. |

| Storage | Store items in a dry and controlled environment. | Ongoing | Prevents damage from humidity or contaminants. |

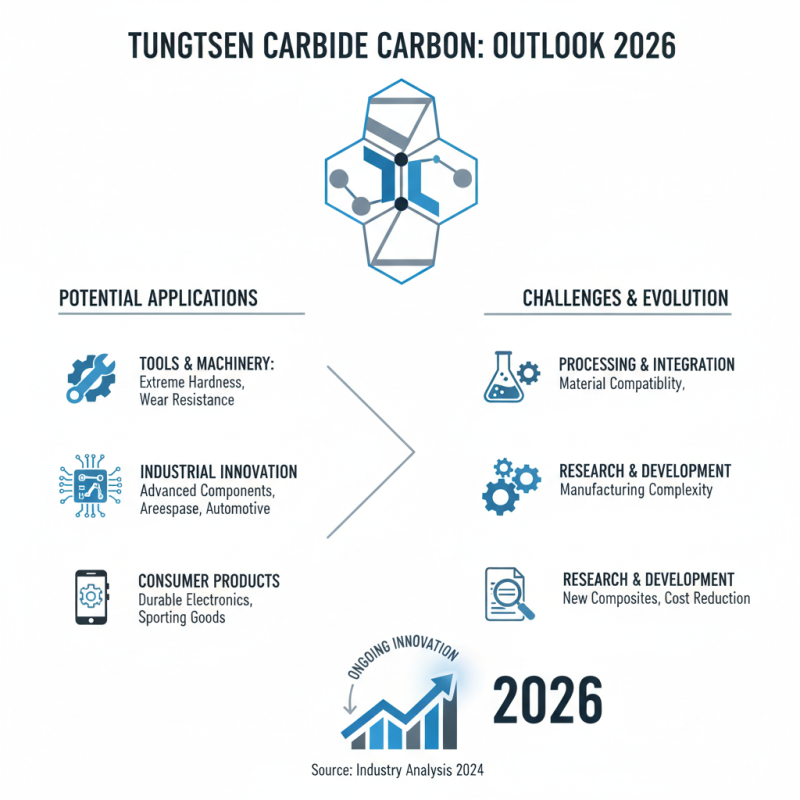

As we look towards 2026, the potential applications of tungsten carbide carbon continue to expand. This composite material is known for its hardness and resistance to wear. Industries are exploring its use in tools, machinery, and modern consumer products. However, the technology is still evolving. There are challenges in processing and integrating tungsten carbide carbon with other materials. This requires ongoing research and development.

Future trends indicate a shift towards more sustainable practices in manufacturing. Companies are working to recycle tungsten carbide carbon from worn-out tools. This could significantly reduce waste and lower production costs. Innovative bonding techniques are being tested, aimed at enhancing the material's performance. But, it is not perfect. Some methods still lead to inconsistencies in durability.

Another area to consider is the environmental impact. While tungsten carbide carbon is durable, mining its raw materials can be damaging. Efforts for eco-friendly extraction methods are in progress. These changes could shape the industry’s future. Although advancements are promising, there's a continuous need for reflection and improvement in processes. Embracing challenges will lead to better solutions.