Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

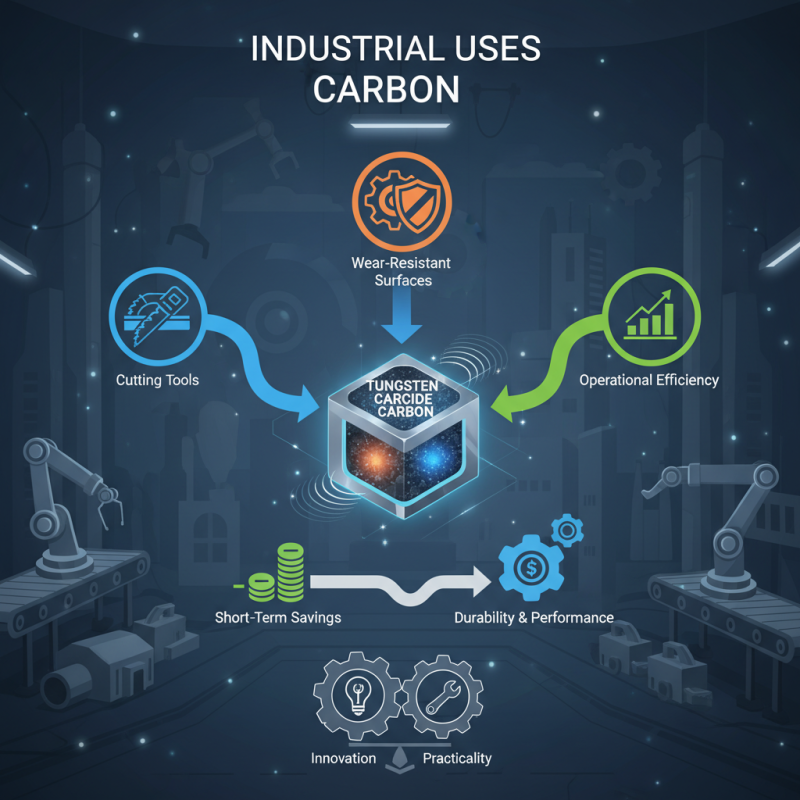

In the industrial sector, the significance of Tungsten Carbide Carbon is growing rapidly. Michael Harper, a leading expert in materials science, emphasizes its versatility, stating, "Tungsten Carbide Carbon is revolutionizing how industries approach durability and performance." This material combines the robustness of tungsten carbide with the unique properties of carbon, making it suitable for various applications.

Tungsten Carbide Carbon can withstand extreme conditions. Its applications range from cutting tools to wear-resistant surfaces in machinery. However, not all industries fully understand its potential. Some fail to recognize the benefits it brings to operational efficiency. Companies often overlook the initial costs in favor of short-term savings.

Implementing Tungsten Carbide Carbon requires careful consideration. It is essential to assess specific needs and potential returns. Some organizations could benefit greatly from its use, while others may find it unnecessary. The challenge lies in striking a balance between innovation and practicality in adopting this advanced material.

Tungsten carbide carbon is a fascinating material. It combines tungsten carbide with carbon, enhancing its hardness and wear resistance. The composition is key to understanding its unique properties. Tungsten carbide typically consists of tungsten and carbon in a specific ratio. This ratio affects its performance in various applications.

The properties of tungsten carbide carbon are impressive. It is known for its high melting point and robustness. These traits make it suitable for demanding industrial environments. Tools made from this material often outperform traditional options. However, the production process can be complex. Achieving the right balance in composition takes careful control and monitoring.

Despite its advantages, there are challenges. Not every application benefits equally from tungsten carbide carbon. Some environments may lead to rapid wear. Surface treatments could help, but they come with added steps. Industry professionals must weigh the benefits against potential drawbacks. Continuous learning and adaptation are essential in harnessing this material effectively.

| Property | Value | Application Area |

|---|---|---|

| Hardness | HV 1800-2200 | Cutting Tools |

| Density | 14.5 g/cm³ | Mining |

| Thermal Conductivity | 80 W/(m·K) | Industrial Machinery |

| Strength | Yield Strength: 2000 MPa | Aerospace |

| Corrosion Resistance | Good | Oil & Gas |

| Wear Resistance | Excellent | Construction |

| Electrical Conductivity | Low | Electronics |

Tungsten carbide carbon is gaining traction in industrial applications due to its unparalleled hardness and wear resistance. Industries like mining and manufacturing frequently utilize this composite material. According to a recent market report, the global tungsten carbide market size is expected to reach $20 billion by 2025. This growth highlights the increasing demand for high-performance materials.

In machining operations, tungsten carbide carbon shines. Its durability reduces tool wear significantly. Studies indicate that tools made from this material can last up to five times longer than traditional options. This longevity not only boosts productivity but also reduces costs. Nevertheless, achieving the right balance in compositions remains a challenge. Variability in purity and particle size can lead to inconsistent performance, which raises questions about quality control.

Applications extend to cutting tools and dies. The exceptional hardness allows for precision cutting in tough materials. However, the brittleness of tungsten carbide carbon can lead to failed parts if not handled properly. Continuous research is essential to enhance its properties and ensure reliability in diverse settings. The industry must address these inconsistencies to fully capitalize on its advantages.

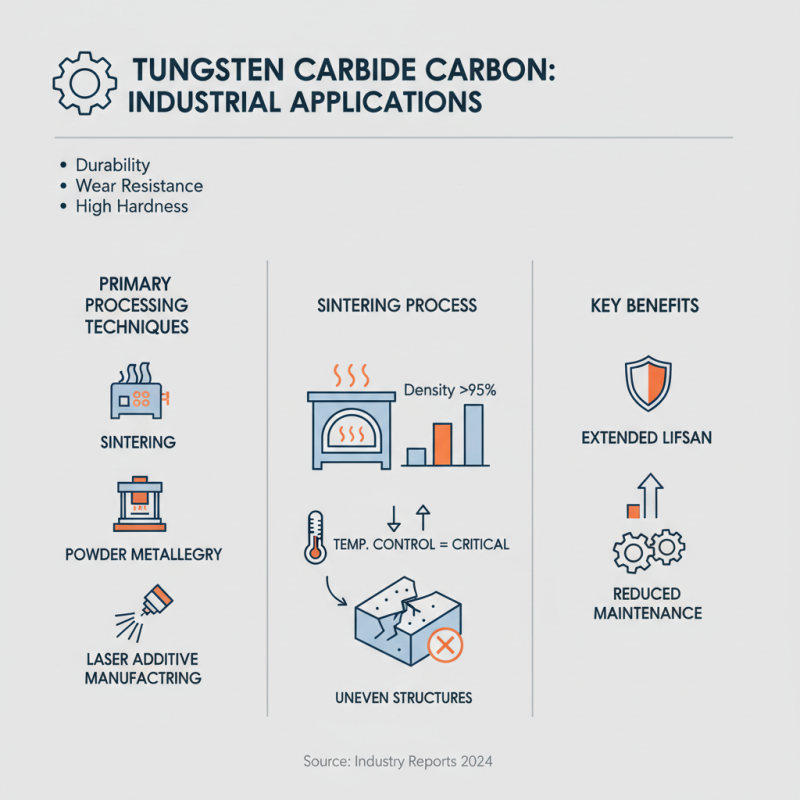

Tungsten carbide carbon is gaining traction in industrial applications due to its durability and wear resistance. The primary processing techniques include sintering, powder metallurgy, and laser additive manufacturing. Sintering, for instance, typically involves heating powdered tungsten and carbon above their melting points. Reports indicate that this method can achieve densities exceeding 95%. However, controlling the temperature is critical. Failure to do so may lead to uneven structures.

Powder metallurgy is a common technique as well. This process allows for the blending of tungsten carbide with other materials to enhance properties. It enables manufacturers to create complex shapes while reducing material waste. Studies show that integrating titanium additives can improve toughness by up to 30%. Yet, precise calculation of the additive quantity is crucial. An excess can negatively impact hardness.

Laser additive manufacturing offers flexibility in creating intricate designs that traditional methods struggle with. This technique allows for layer-by-layer construction. Reports suggest that parts produced this way exhibit superior surface finishes. However, the complexity of the process may introduce challenges in consistency. Operators need extensive training to maximize potential benefits. Balancing efficiency with quality remains an ongoing challenge in the industry.

Tungsten carbide carbon is increasingly recognized for its unique advantages in various industrial applications. Its exceptional hardness makes it a prime choice for cutting tools and wear-resistant surfaces. This leads to extended tool life, reducing the frequency of replacements and maintenance. In environments where precision is critical, such as aerospace and automotive sectors, this durability provides significant savings.

Applications in mining and drilling are noteworthy. The intense resistance to abrasion ensures that tools can withstand harsh conditions. However, the material can be brittle under certain circumstances. This poses challenges during manufacturing and machining processes. Careful handling and processing are essential to avoid cracking and other damages. Awareness of these limitations can enhance performance and increase safety in operations.

Tungsten carbide carbon's versatility also spans into heavy machinery, construction, and manufacturing. Its ability to perform under extreme pressure has proven valuable. However, not all industries may see the same benefits. Each application should be assessed individually. Understanding the trade-offs in cost, performance, and durability is crucial before adoption. Such an analysis allows industries to make informed decisions.

Tungsten carbide carbon is a robust material used in various industrial applications. Its durability is impressive, but safety and environmental issues arise during its use. Exposure to fine particles during machining can pose respiratory risks. Studies indicate that inhaling such particles can lead to lung diseases. According to the World Health Organization, industrial workers are often at higher risk due to prolonged exposure.

Moreover, the environmental impact of tungsten carbide production should not be overlooked. This material is derived from heavy metals, which can leach into soil and groundwater. A report from a leading environmental agency highlighted that improper disposal practices can lead to significant ecological damage. As industries adopt tungsten carbide carbon, they must ensure proper waste management systems are in place.

Compliance with safety standards is crucial. Industries should implement strict guidelines to minimize risks associated with this material. Regular training for workers is essential for promoting safe handling practices. Ultimately, while tungsten carbide carbon offers remarkable strength, the potential hazards necessitate ongoing reflection and improvement in safety measures.