0102030405

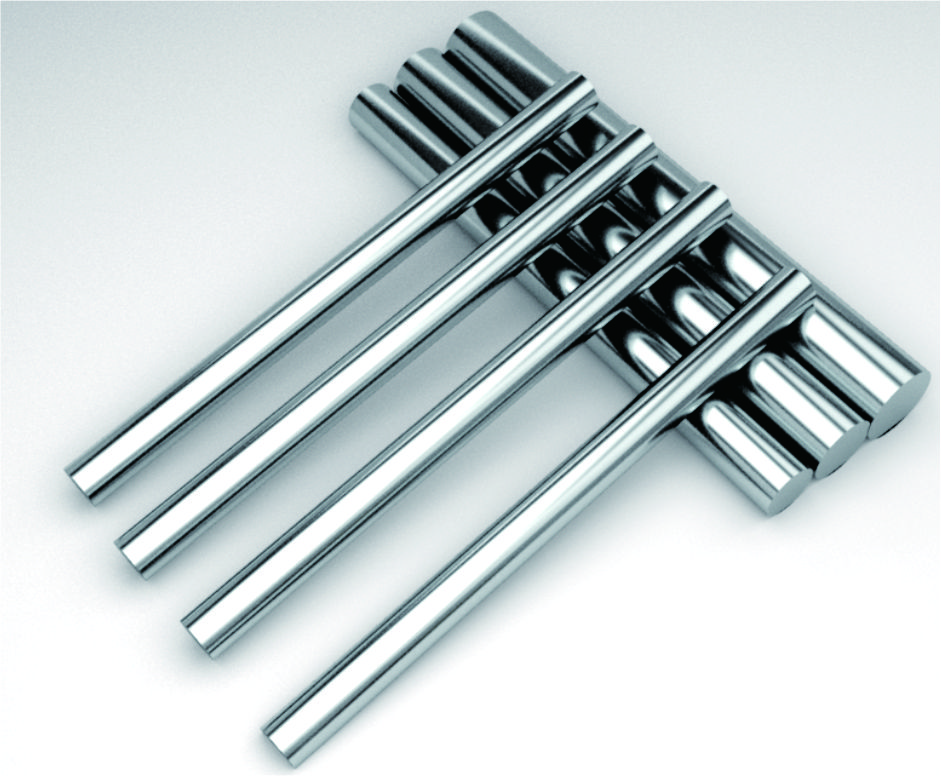

SC Type For Ball Nose Cylider Shape Burr

product description

Carbide Burr Head (SC type) for Ball Nose Cylinderical Carbide Burr(Double Cut&Single Cut)

specification

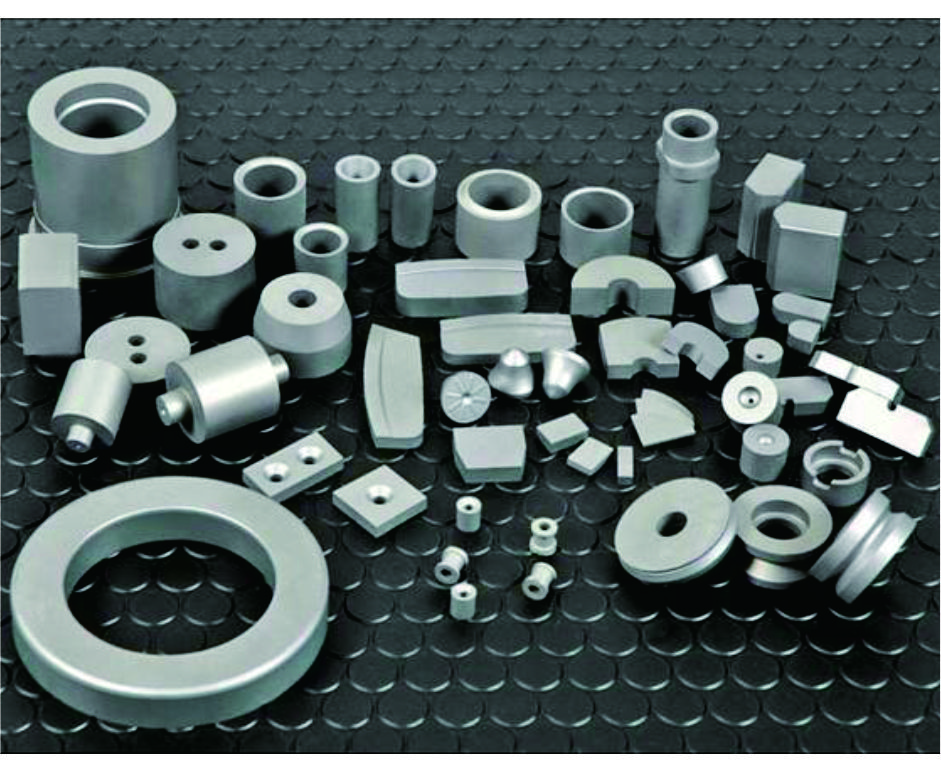

Full Series of SA-SN to cover the whole series of Carbide Burr, please turn to download page for more information.

Material Property

| Carbide Grade\Property\Application | |||||

| GB Grade | I S O Grade | HRA≥ | (g/cm³)≥ | (N/mm2)≥ | Application |

| YG6X | K10 | 91.5 | 14.89 | 2870 | Suitable for producing carbide burr, especially suitable for processing non-ferrous metals and non-metallic materials. |

| YG8 | K20-K30 | 90.8 | 14.80 | 2850 | Suitable for making Dremel rotary burr. |

| FD7 | K30 | 90.8 | 14.80 | 2850 | Suitable for making Dremel rotary burr. |

| FK30 | K20-K30 | 91.6 | 14.45 | 3500 | Suitable for producing carbide burr, especially suitable for processing non-ferrous metals and non-metallic materials. |

Advantage

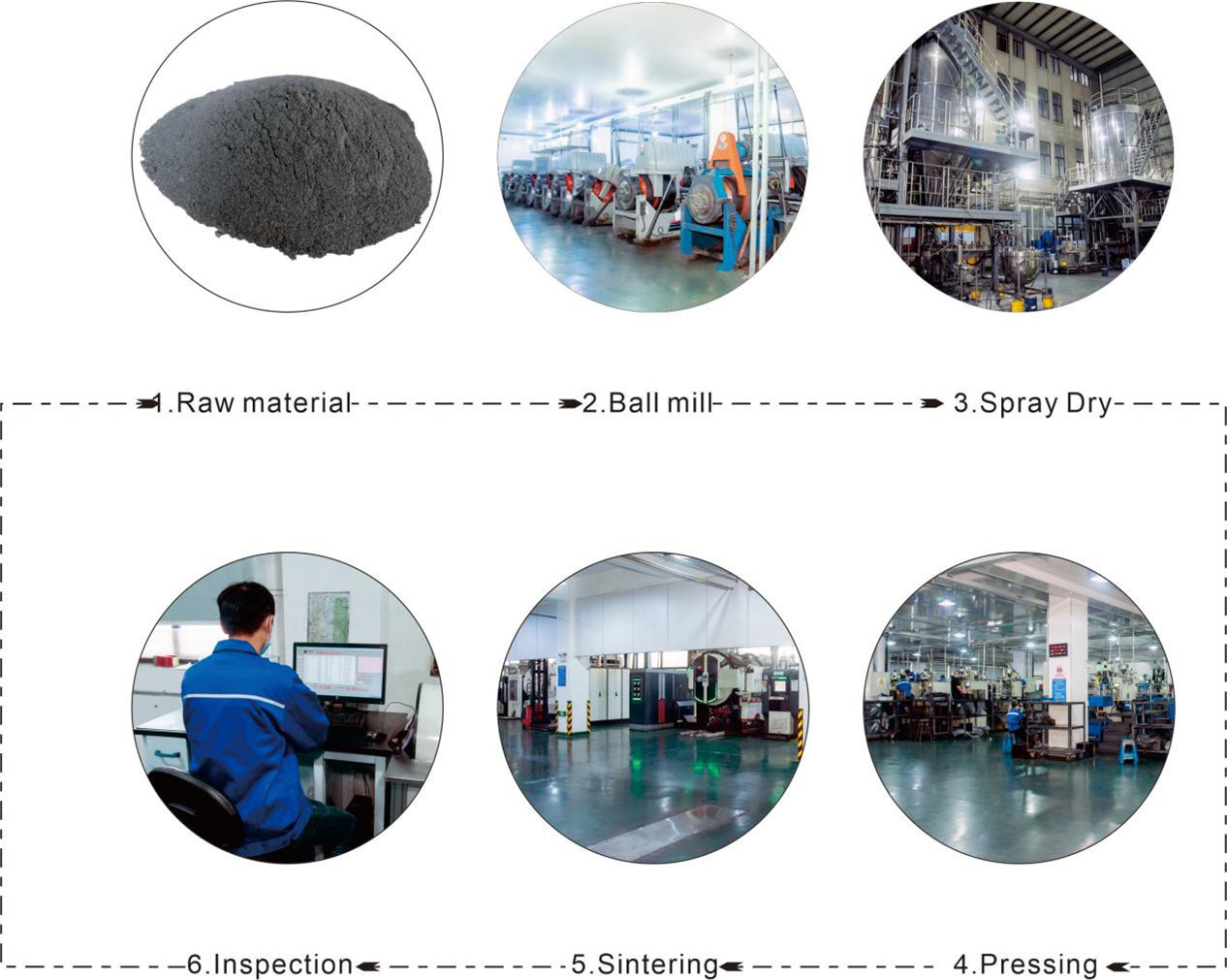

1.Control of raw materials is crucial. We strictly screen tungsten powder, cobalt powder, etc. to ensure that their purity and particle size meet high standards.

2.Strict quality control is our lifeline, from raw material screening to finished product inspection, every process follows the strictest standards, only to deliver impeccable products to customers.

3.Our technical team is composed of a group of industry elites who possess profound professional knowledge and rich practical experience, constantly pursuing technological breakthroughs.

4.Technological innovation is the core driving force for development, and the constantly emerging new methods and processes have greatly improved product performance and production efficiency.

5.In the tungsten carbide industry, customized services are becoming increasingly important, and products are carefully designed according to the special needs of customers to meet diverse application scenarios.

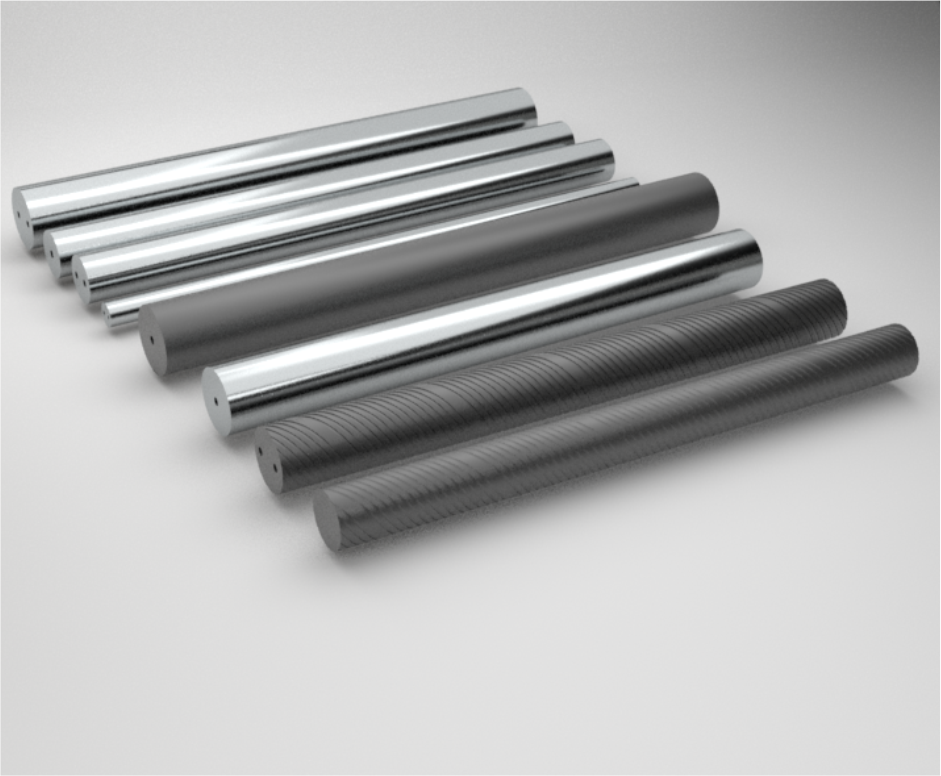

6.Our surface treatment technology continues to innovate and develop, integrating the latest technological achievements, from electrolytic polishing to sandblasting treatment, to meet various complex needs.

7. We strengthen the management of raw material procurement, establish long-term cooperation with high-quality suppliers, strive for more favorable prices and payment terms, and effectively control production costs.

Process

Solution

Why choose us

Our testing methods in the tungsten carbide industry are very comprehensive, covering hardness testing, grain size analysis, porosity testing, etc., ensuring excellent product performance.

Our production process focuses on detail control, with strict quality inspection points at every stage. Once problems are found, they are promptly resolved to ensure that the products are delivered to customers without any defects.

Most of our suppliers are leading enterprises in the industry, with excellent technical strength, advanced production equipment, and experienced professional teams, providing customers with first-class products and services.

Our company is located near Shanghai Port and Ningbo Port, and the advantages brought by convenient ports are unparalleled. The efficient and fast transportation of goods greatly reduces logistics and time costs.