0102030405

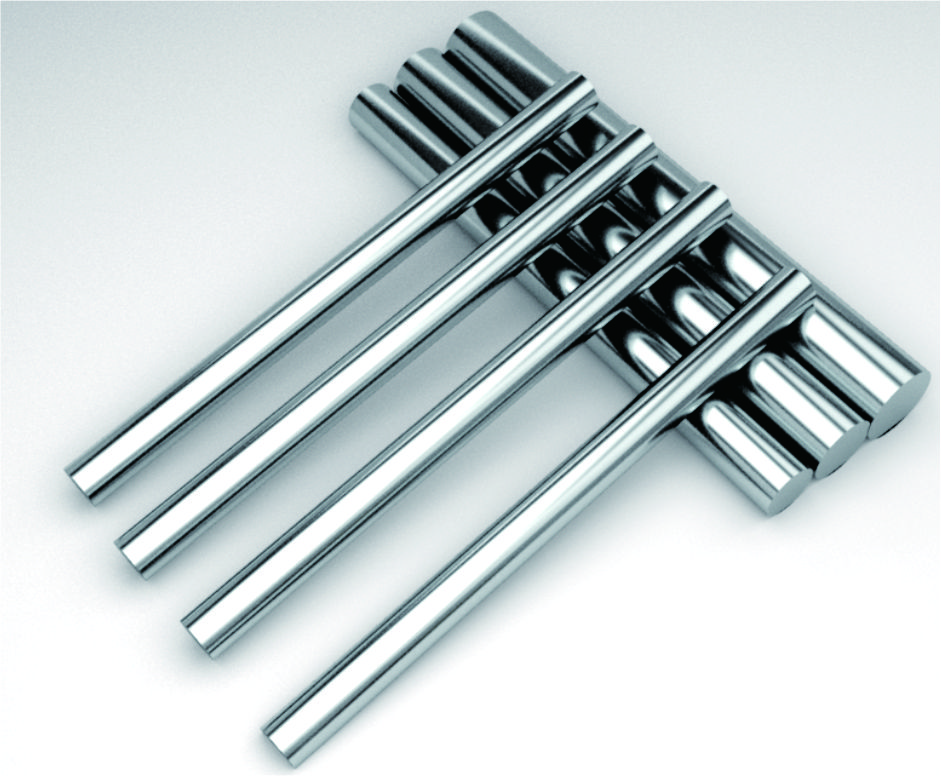

SD Type For Ball Shape Burr

product description

Carbide Burr Head (SD type) for Ball Shape Carbide Burr(Double Cut&Single Cut)

specification

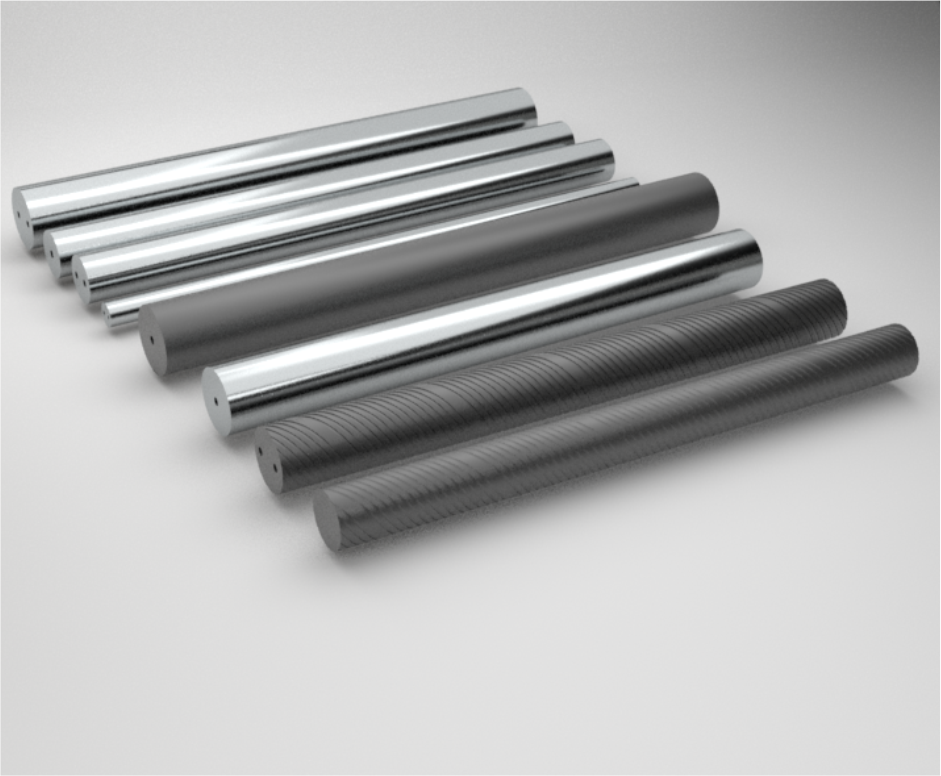

Full Series of SA-SN to cover the whole series of Carbide Burr, please turn to download page for more information.

Material Property

| Carbide Grade\Property\Application | |||||

| GB Grade | I S O Grade | HRA≥ | (g/cm³)≥ | (N/mm2)≥ | Application |

| YG6X | K10 | 91.5 | 14.89 | 2870 | Suitable for producing carbide burr, especially suitable for processing non-ferrous metals and non-metallic materials. |

| YG8 | K20-K30 | 90.8 | 14.80 | 2850 | Suitable for making Dremel rotary burr. |

| FD7 | K30 | 90.8 | 14.80 | 2850 | Suitable for making Dremel rotary burr. |

| FK30 | K20-K30 | 91.6 | 14.45 | 3500 | Suitable for producing carbide burr, especially suitable for processing non-ferrous metals and non-metallic materials. |

Advantage

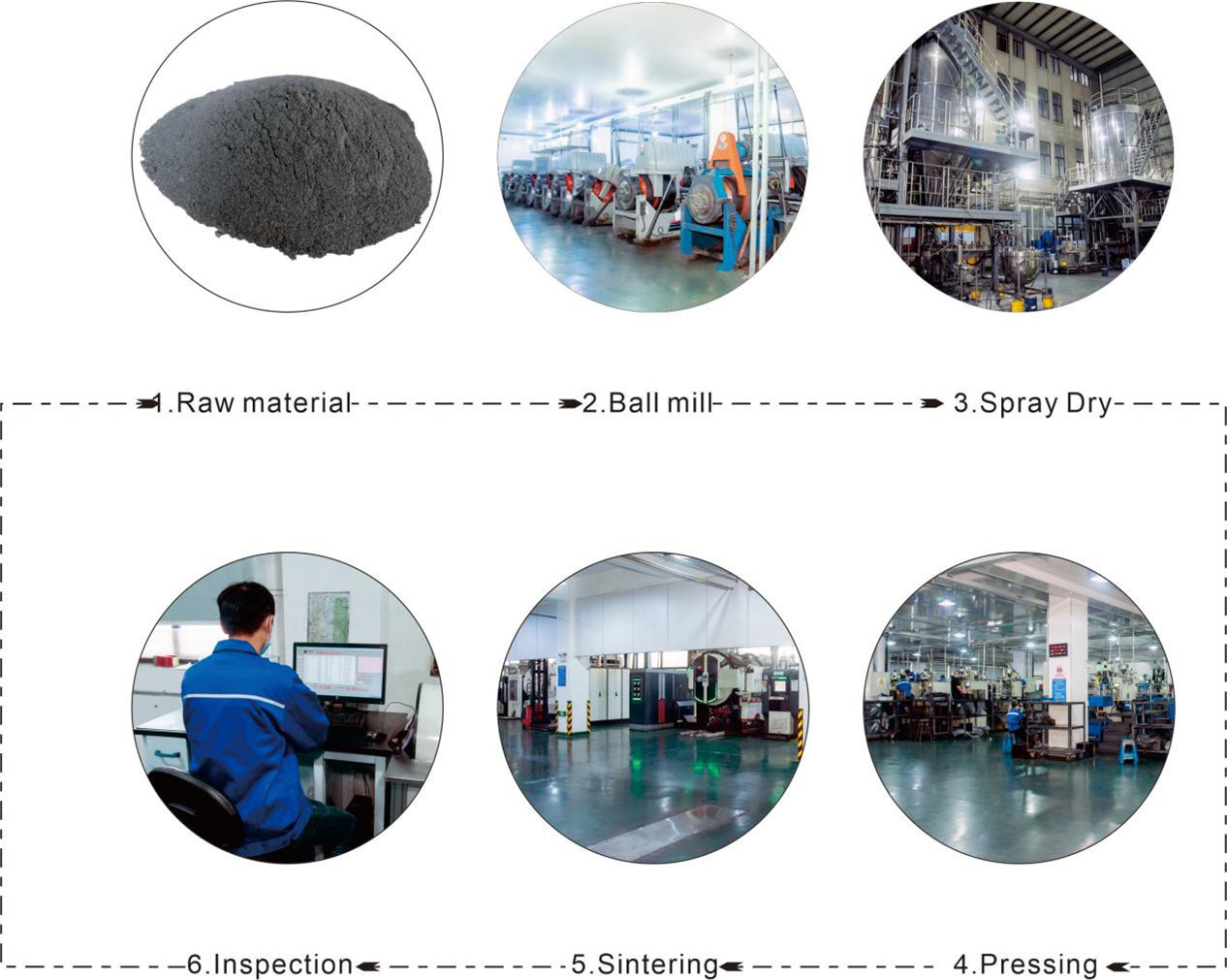

1.The control of raw materials is extremely strict. We have established a supplier evaluation system to ensure the stable and reliable quality of raw materials.supplier-Stock Market listed.(cooperation relationship established since established 2012)

2.Strict material incoming and pre-delivery inspection ensures no unqualified material used and unqualified goods delivered.

3.Our technical team is the core competitiveness, they are proficient in various process technologies and can accurately control every production process.

4.Technological innovation is the foundation for enterprises to establish themselves. Continuously exploring new sintering processes, optimizing surface treatment technologies, and enhancing market competitiveness.

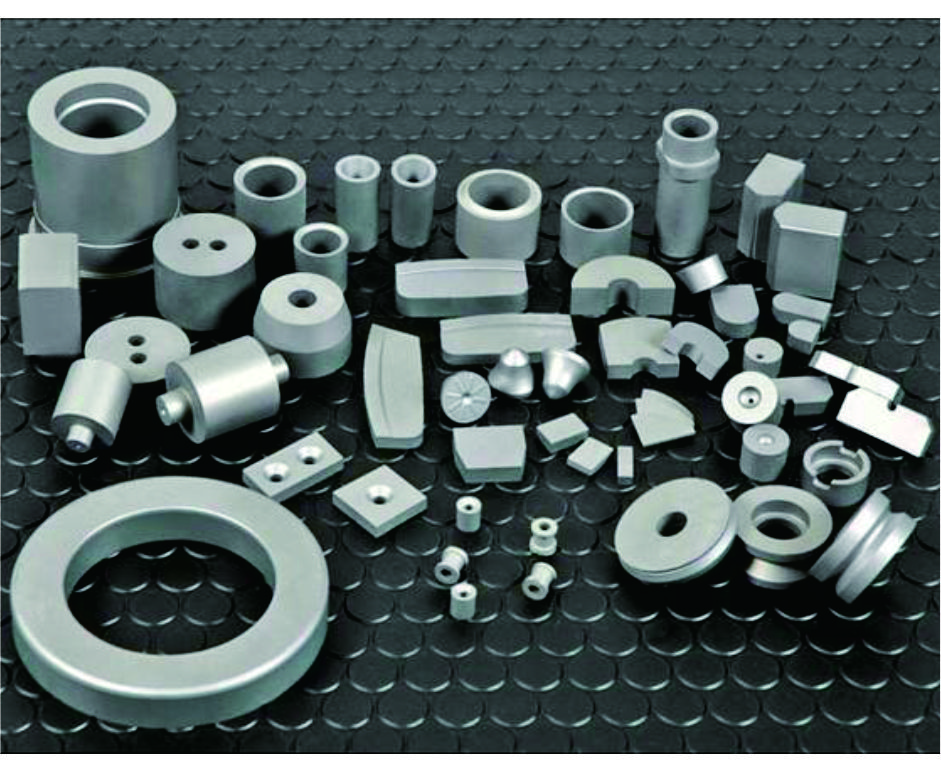

5.In the tungsten carbide industry, customization has become a competitive advantage. By deeply understanding customer needs, we can provide exclusive solutions from materials to shapes.

6.Our surface treatment technology has a professional team and excellent equipment, which can achieve industry-leading levels in both mechanical grinding and electrochemical treatment.

7.Cost optimization is the key to enhancing competitiveness for enterprises, and we adopt centralized procurement and other methods to reduce raw material costs.

Process

Solution

Why choose us

Our testing methods in the tungsten carbide industry focus on details, from chemical composition analysis to microstructure observation, and strictly control every testing process.

Our production process fully considers environmental factors, using energy-saving equipment and environmentally friendly materials to improve production efficiency while minimizing adverse effects on the environment.

Our suppliers are outstanding in the industry. They not only have modern production facilities and professional R&D teams, but also provide us with high-quality products through efficient production processes and strict quality control.

Due to its proximity to Shanghai Port and Ningbo Port, we have enjoyed many benefits brought by port convenience, including a variety of route options and convenient customs clearance processes, making trade more smooth.