0102030405

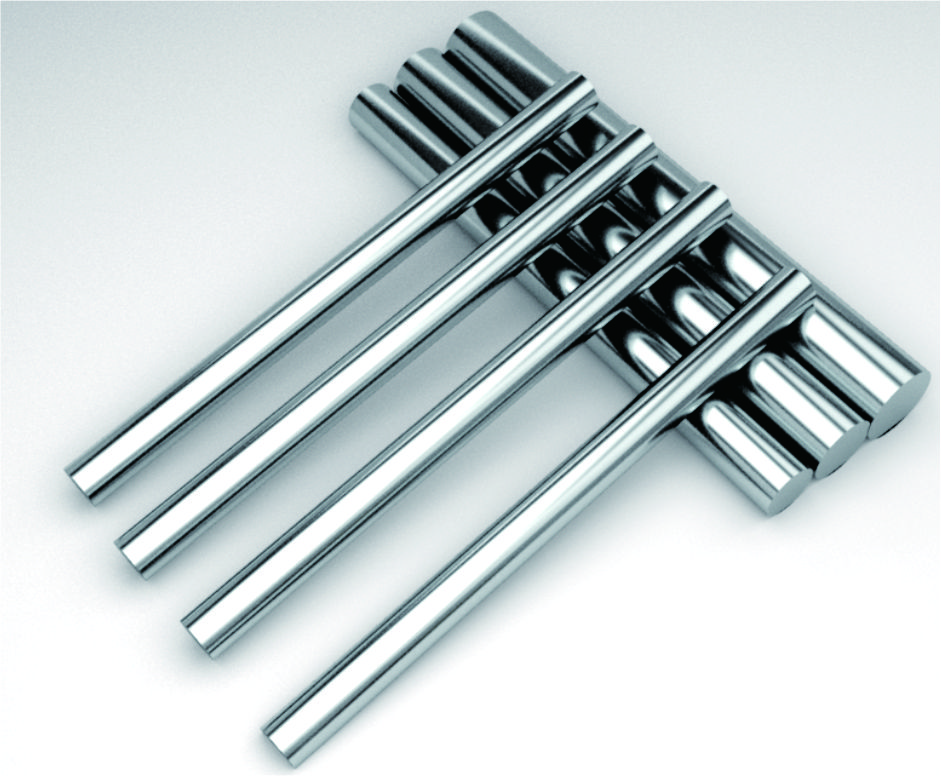

SE Type For Oval Shape Burr

product description

Carbide Burr Head (SE type) for Oval Shape Carbide Burr(Double Cut&Single Cut)

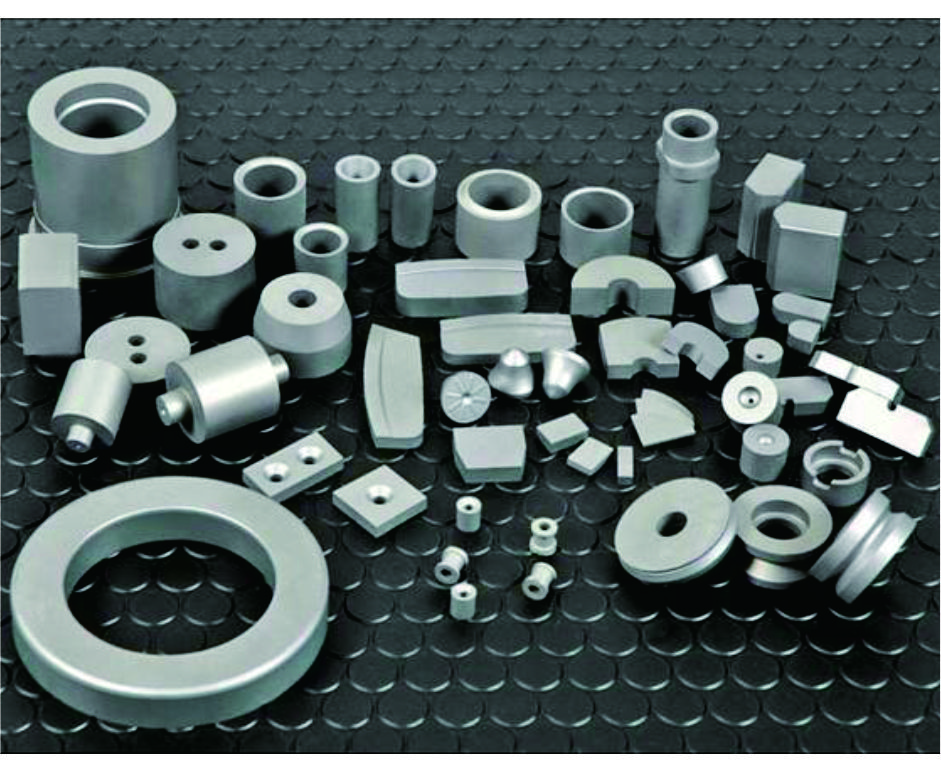

specification

Full Series of SA-SN to cover the whole series of Carbide Burr, please turn to download page for more information.

Material Property

| Carbide Grade\Property\Application | |||||

| GB Grade | I S O Grade | HRA≥ | (g/cm³)≥ | (N/mm2)≥ | Application |

| YG6X | K10 | 91.5 | 14.89 | 2870 | Suitable for producing carbide burr, especially suitable for processing non-ferrous metals and non-metallic materials. |

| YG8 | K20-K30 | 90.8 | 14.80 | 2850 | Suitable for making Dremel rotary burr. |

| FD7 | K30 | 90.8 | 14.80 | 2850 | Suitable for making Dremel rotary burr. |

| FK30 | K20-K30 | 91.6 | 14.45 | 3500 | Suitable for producing carbide burr, especially suitable for processing non-ferrous metals and non-metallic materials. |

Advantage

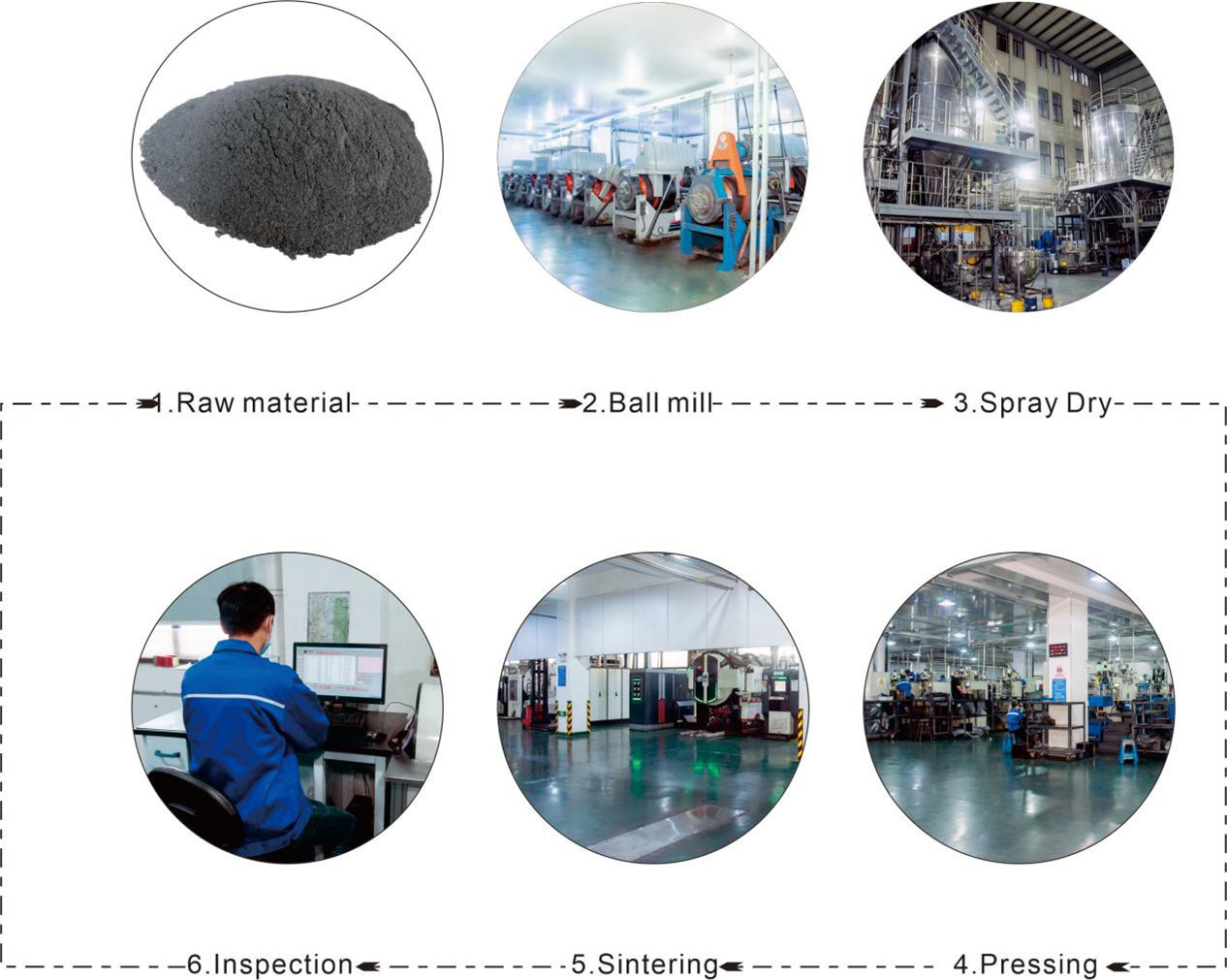

1.We attach great importance to raw material control and conduct multidimensional testing on each type of raw material, striving for perfect quality.

2.Our quality control system is like a strong line of defense, built together by a professional quality inspection team, advanced testing equipment, and a sound management system to ensure product quality is flawless.

3.Our technical team is committed to improving product quality and meeting the diverse needs of customers with a rigorous attitude and exquisite skills.

4.For the tungsten carbide industry, customization is the key to meeting market segmentation needs and accurately creating alloy products that meet specific working conditions.

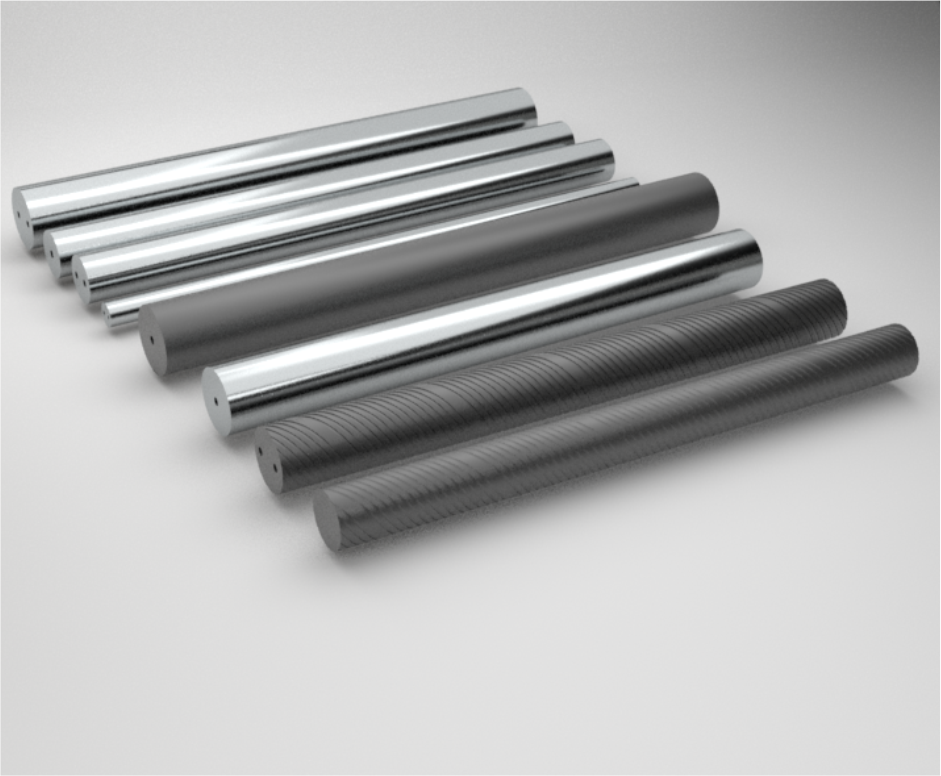

5.Our surface treatment technology is top-notch, and through precise process control such as acid pickling and passivation, flame quenching, we endow our products with excellent quality and durability.

6.The power of technological innovation cannot be underestimated. Advanced grinding technology and innovative mold design promote product quality to a new level.

7.In the industry, cost optimization requires comprehensive consideration. We start from the production process to improve efficiency and reduce energy consumption.

Process

Solution

Why choose us

Our testing methods in the tungsten carbide industry are diverse, including bending strength testing, impact toughness testing, and hardness gradient measurement,etc.

Our production process has high flexibility and scalability, and can quickly adjust production plans and processes according to changes in market demand, meeting the personalized customization needs of different customers.

Our suppliers have strong comprehensive strength, from careful selection of raw materials, to the application of advanced technology, and to comprehensive after-sales service, every aspect demonstrates their excellent professional competence and dedication.

The geographical advantage of being close to Shanghai Port and Ningbo Port has provided us with port convenience. Whether it is the loading and unloading of import and export goods, or the arrangement of warehousing and logistics, it is extremely convenient and efficient.