0102030405

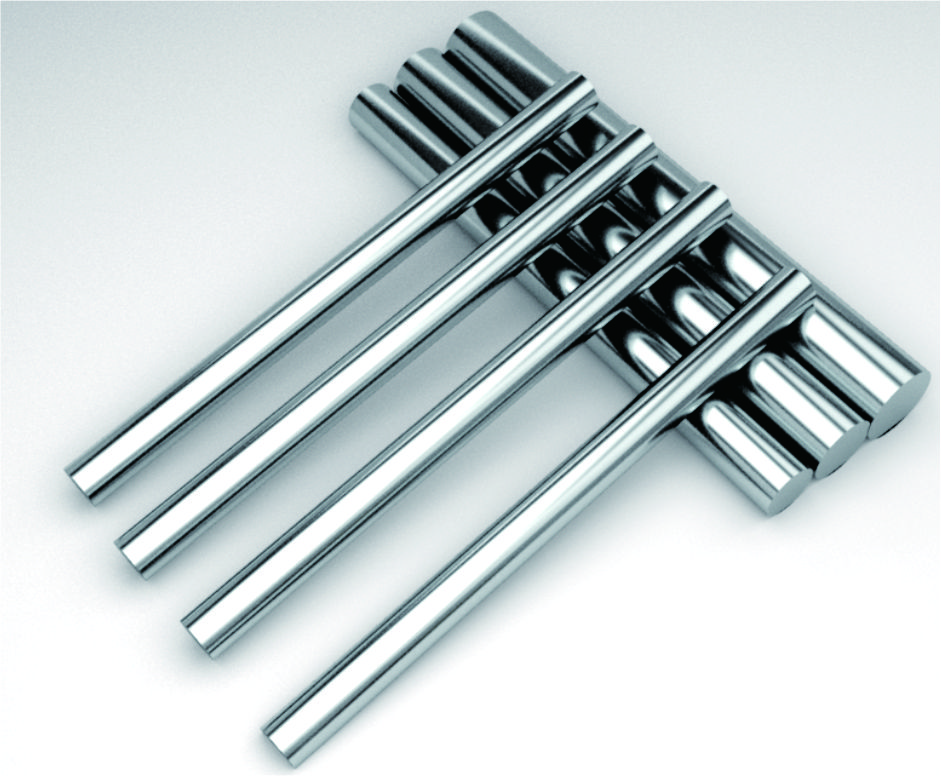

SF Type For Tree Shape Burr

product description

Carbide Burr Head (SF type) for Tree Shape Carbide Burr(Double Cut&Single Cut)

specification

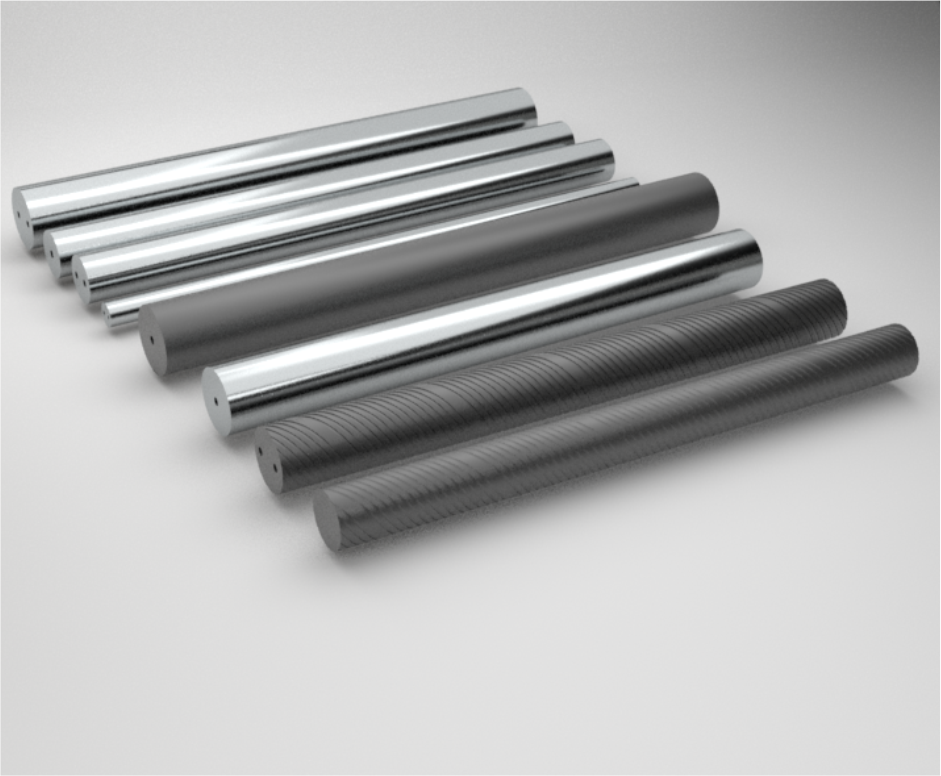

Full Series of SA-SN to cover the whole series of Carbide Burr, please turn to download page for more information.

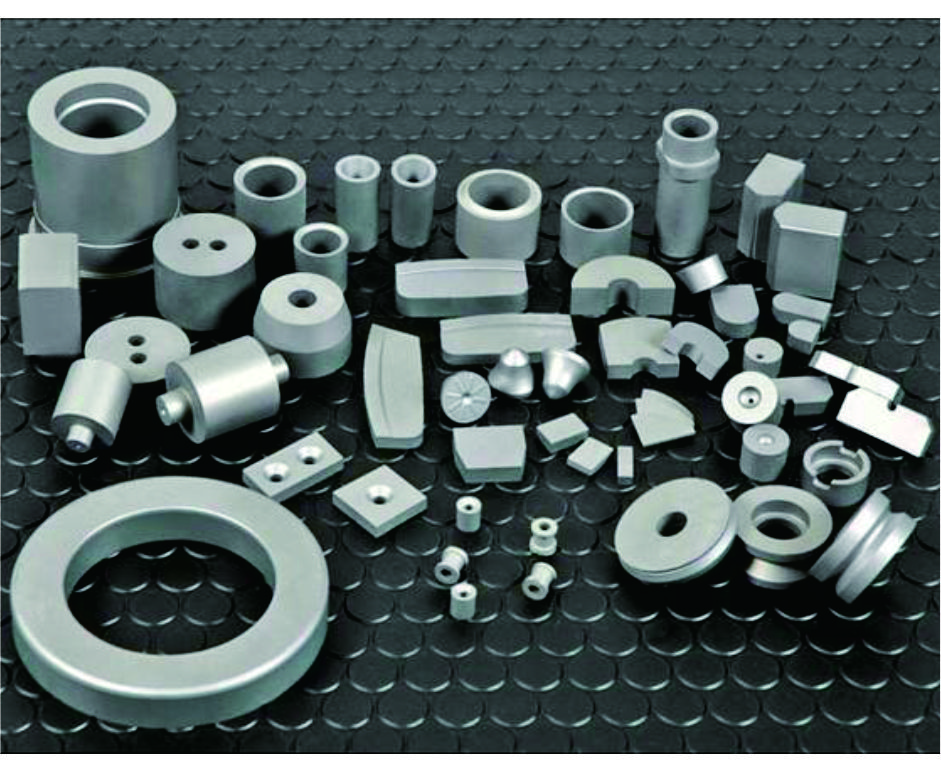

Material Property

| Carbide Grade\Property\Application | |||||

| GB Grade | I S O Grade | HRA≥ | (g/cm³)≥ | (N/mm2)≥ | Application |

| YG6X | K10 | 91.5 | 14.89 | 2870 | Suitable for producing carbide burr, especially suitable for processing non-ferrous metals and non-metallic materials. |

| YG8 | K20-K30 | 90.8 | 14.80 | 2850 | Suitable for making Dremel rotary burr. |

| FD7 | K30 | 90.8 | 14.80 | 2850 | Suitable for making Dremel rotary burr. |

| FK30 | K20-K30 | 91.6 | 14.45 | 3500 | Suitable for producing carbide burr, especially suitable for processing non-ferrous metals and non-metallic materials. |

Advantage

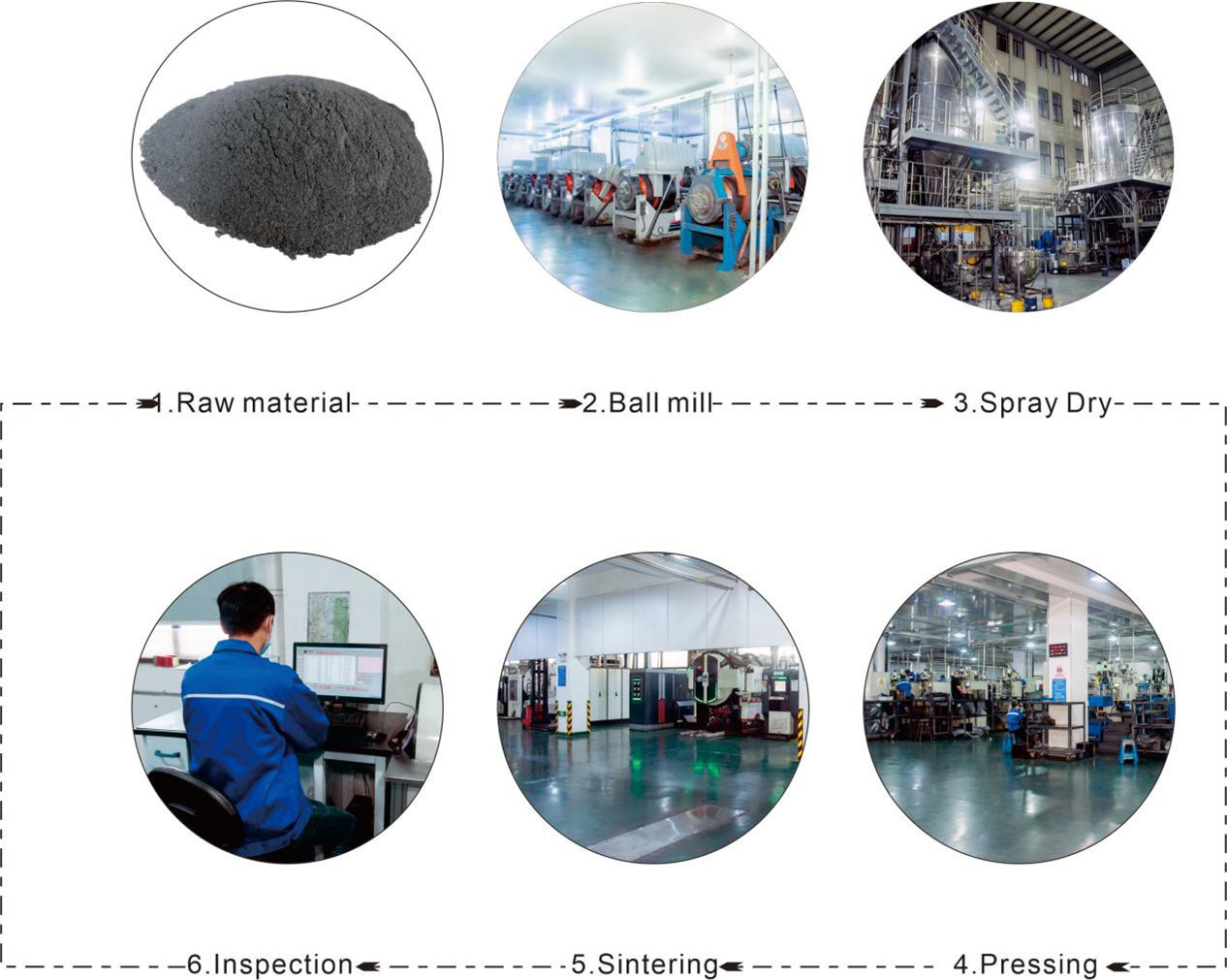

1. Raw material control is a key link, and we cooperate with high-quality suppliers to ensure that the raw materials have excellent physical and chemical properties.

2.We always adhere to the ultimate pursuit of quality, with a rigorous attitude and meticulous processes, to carry out strict quality control, and never miss any subtle point that may affect product quality.

3.Our technical team continuously learns and introduces advanced technologies, combined with our own research and development achievements, to inject strong impetus into the development of the enterprise.

4.Technological innovation is an eternal theme, and the development of new binders and the synthesis of high-performance tungsten carbides have expanded their application fields.

5.Our surface treatment technology has unique advantages, integrating multiple efficient methods such as vacuum treatment and laser processing to achieve the ultimate surface quality of our products.

6.In the field of tungsten carbides, the charm of customization lies in tailoring to different industry standards and working environments to manufacture ideal alloy tools.

7.Cost optimization is a long-term and systematic task, and we utilize technological innovation to reduce waste in the production process.

Process

Solution

Why choose us

Our testing methods in the tungsten carbide industry have formed a complete system, from quality screening of raw materials to comprehensive performance evaluation of finished products, with no omissions.

Our production process emphasizes teamwork, close cooperation between departments, smooth information sharing, and an efficient closed-loop system from research and development design to production and manufacturing, and then to after-sales service.

Our suppliers have a high reputation in the market, relying on years of accumulated rich experience, innovative technological means, and precise grasp of customer needs, they consistently deliver high-quality products to us.

Located in the vicinity of Shanghai Port and Ningbo Port, fully utilizing the convenience of the port, we can quickly respond to domestic and international market demands, timely allocate goods, and enhance market competitiveness.