0102030405

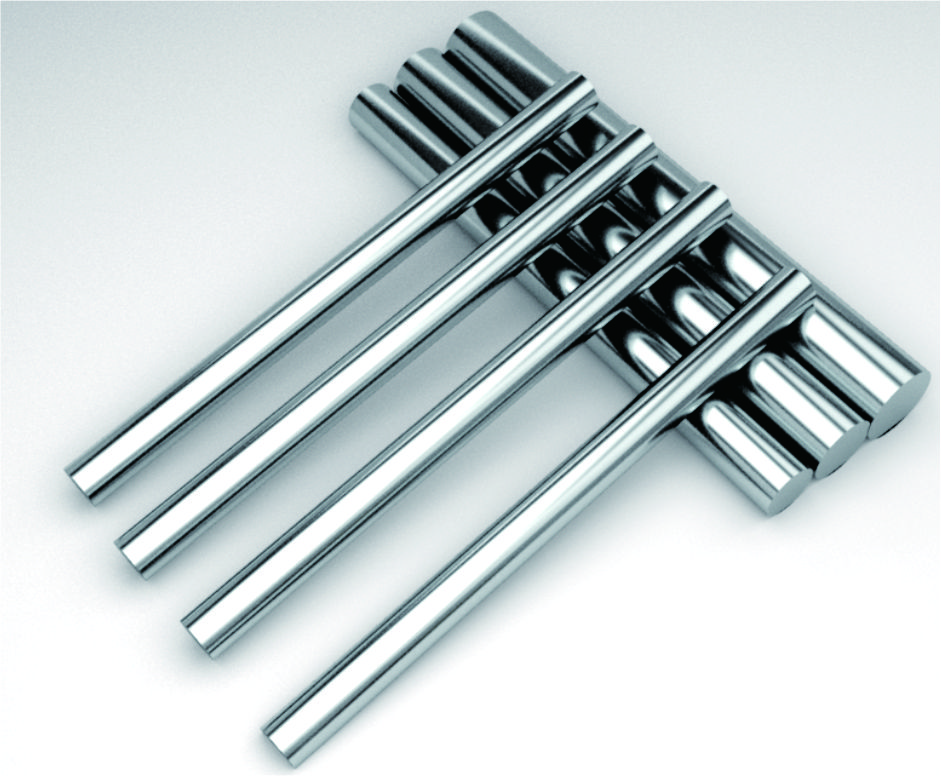

SG Type For Pointed Tree Shape Burr

product description

Carbide Burr Head (SG type) for Pointed Tree Shape Carbide Burr(Double Cut&Single Cut)

specification

Full Series of SA-SN to cover the whole series of Carbide Burr, please turn to download page for more information.

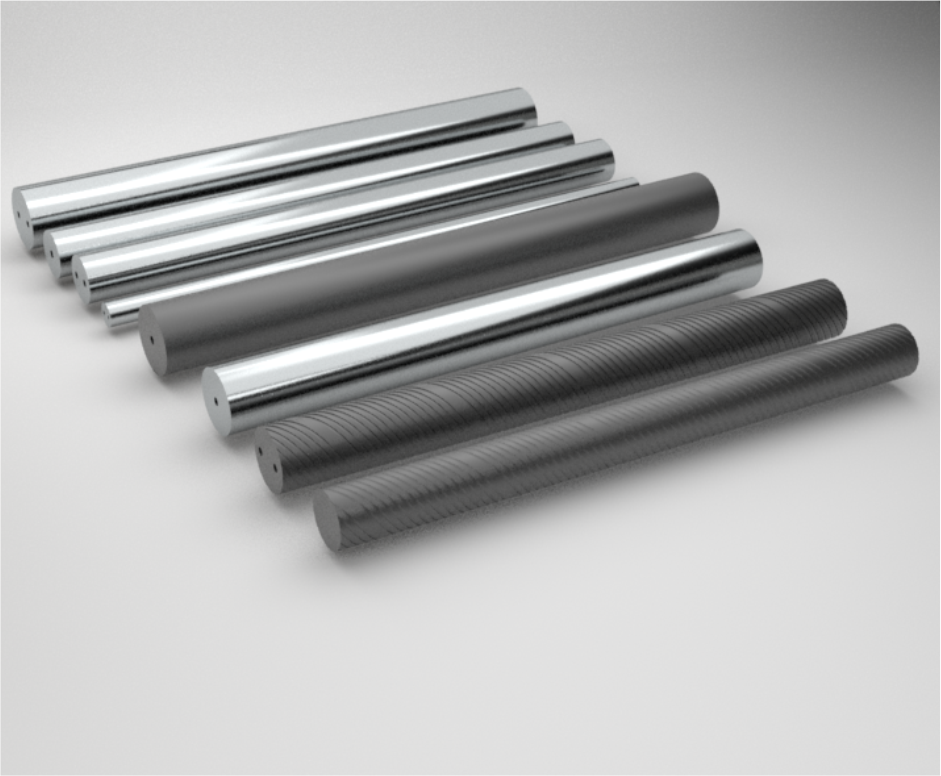

Material Property

| Carbide Grade\Property\Application | |||||

| GB Grade | I S O Grade | HRA≥ | (g/cm³)≥ | (N/mm2)≥ | Application |

| YG6X | K10 | 91.5 | 14.89 | 2870 | Suitable for producing carbide burr, especially suitable for processing non-ferrous metals and non-metallic materials. |

| YG8 | K20-K30 | 90.8 | 14.80 | 2850 | Suitable for making Dremel rotary burr. |

| FD7 | K30 | 90.8 | 14.80 | 2850 | Suitable for making Dremel rotary burr. |

| FK30 | K20-K30 | 91.6 | 14.45 | 3500 | Suitable for producing carbide burr, especially suitable for processing non-ferrous metals and non-metallic materials. |

Advantage

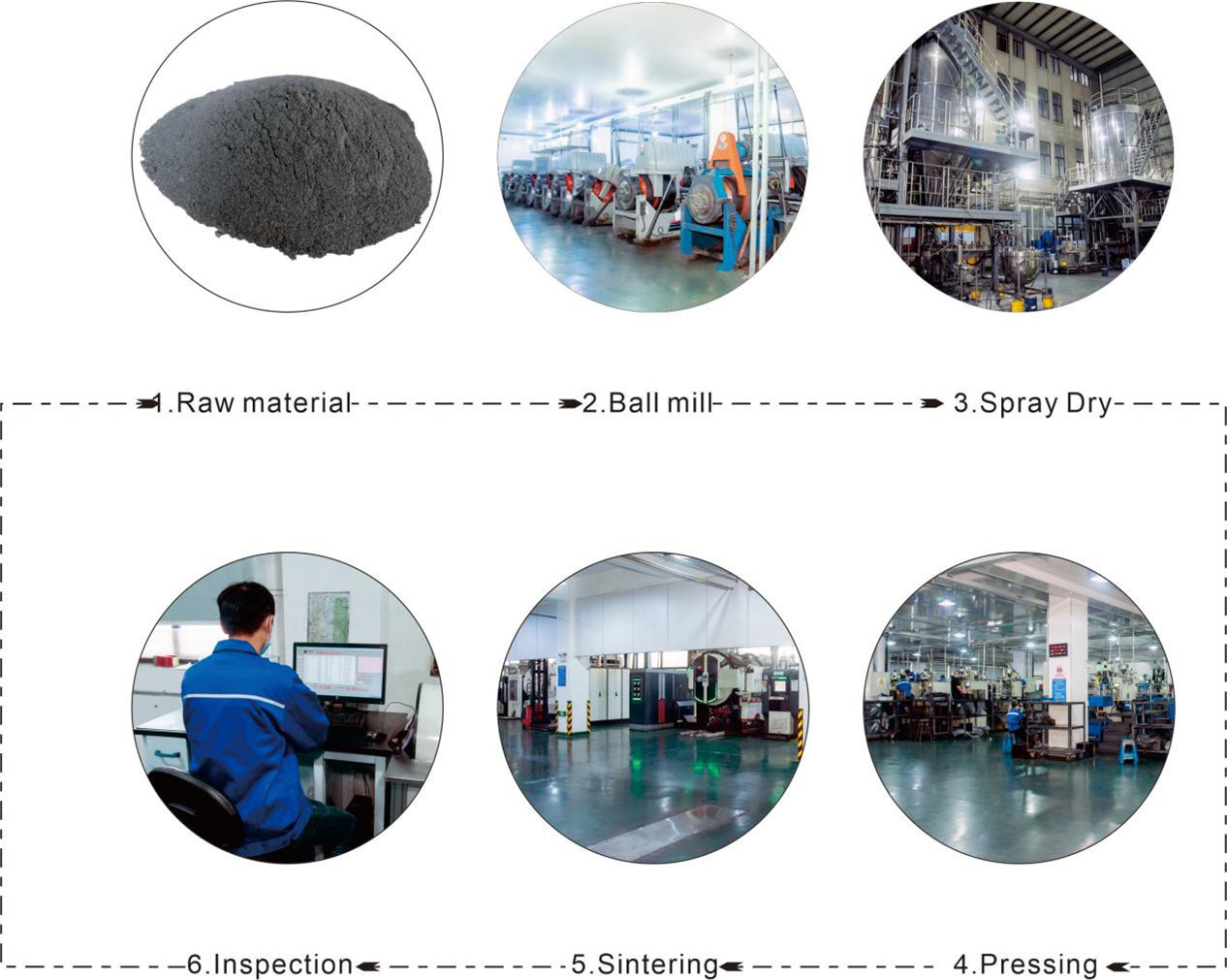

1.We have never relaxed our control over raw materials and have established a professional testing team to conduct comprehensive and meticulous analysis and inspection of the raw materials.

2.With a meticulous spirit and zero tolerance principle, we strictly control product quality in all aspects and at multiple levels, making high quality our eternal commitment.

3.Our technical team is like a pillar of strength, relying on wisdom and perseverance to successfully overcome one difficulty after another when facing technical difficulties.

4.The progress of the tungsten carbide industry is inseparable from technological innovation, innovative testing methods, and cutting-edge manufacturing processes, which drive the entire industry forward,that's what we are insist on.

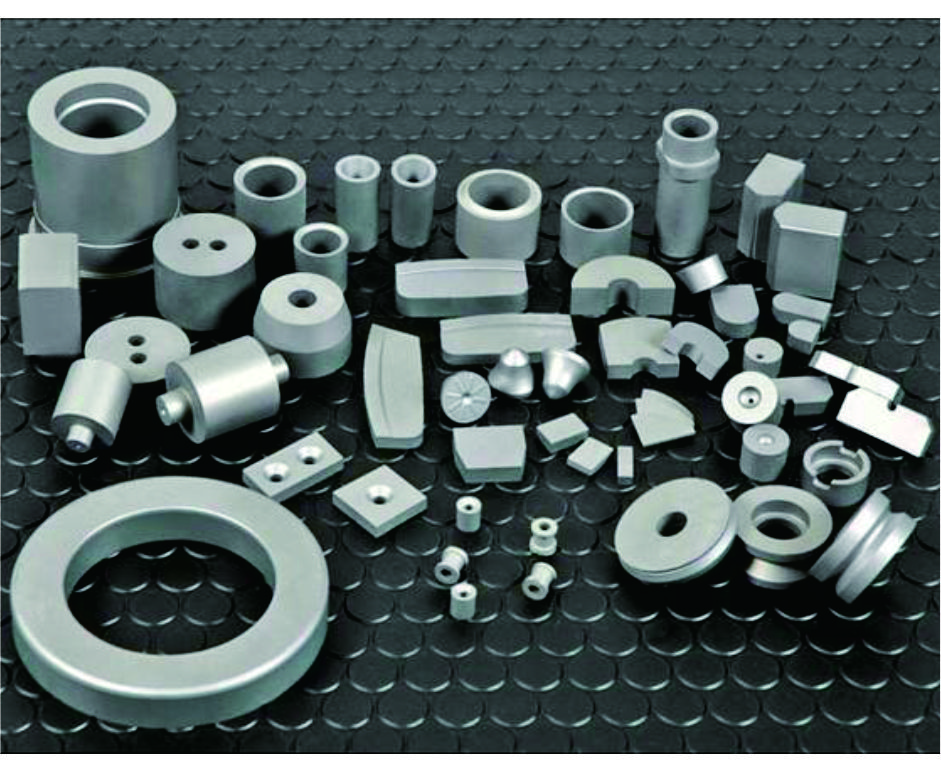

5.The development of the tungsten carbide industry cannot be separated from the promotion of customization, meeting personalized needs, creating exclusive brand image, and expanding market space.

6.Our surface treatment technology is powerful, adopting scientific processes and strict standards, ensuring high-quality results in both oxidation and nitriding treatments.

7.Cost optimization cannot be achieved without scientific planning. We upgrade and transform equipment to reduce maintenance costs.

Process

Solution

Why choose us

Our testing methods in the tungsten carbide industry are professional and precise, ensuring product dimensional accuracy meets standards through high-precision measuring tools and advanced testing equipment.

Our production process strictly follows the principles of safety production, providing employees with comprehensive safety training and protective equipment, conducting regular equipment maintenance and safety inspections, and ensuring the safety and orderliness of the production process.

Our supplier is a trusted partner with a large production scale and efficient management system, able to quickly respond to our needs, while ensuring product quality and providing highly competitive prices.

The proximity to Shanghai Port and Ningbo Port allows us to fully enjoy port convenience, advanced port facilities, and professional logistics services, injecting strong impetus into the development of enterprises.