0102030405

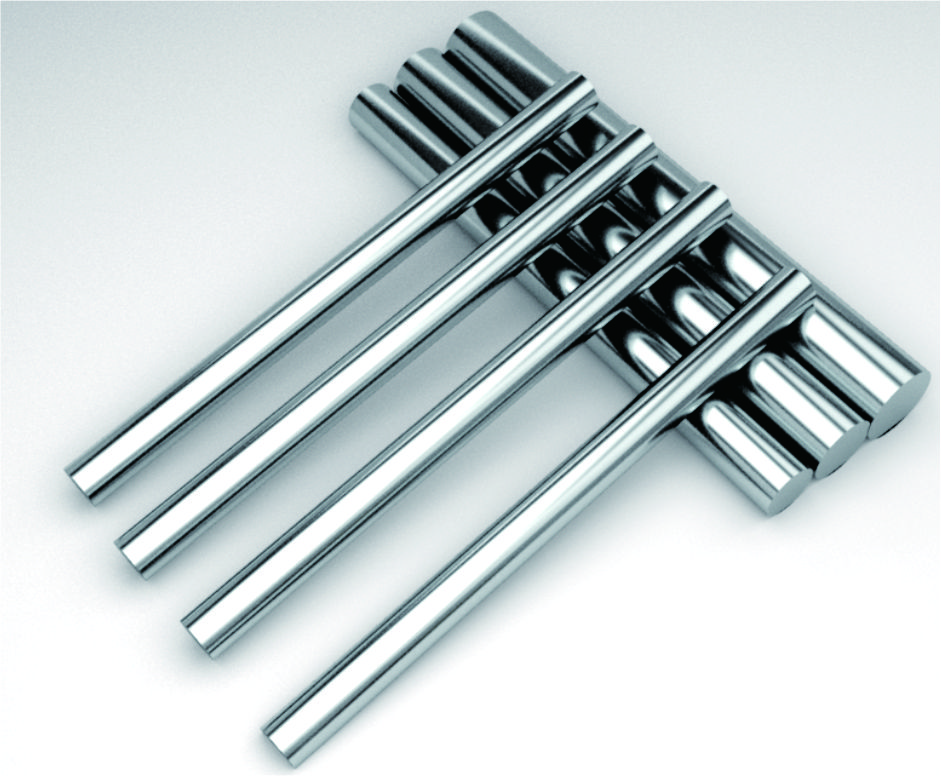

SH Type For Flame Shape Burr

product description

Carbide Burr Head (SH type) for Flame Shape Carbide Burr(Double Cut&Single Cut)

specification

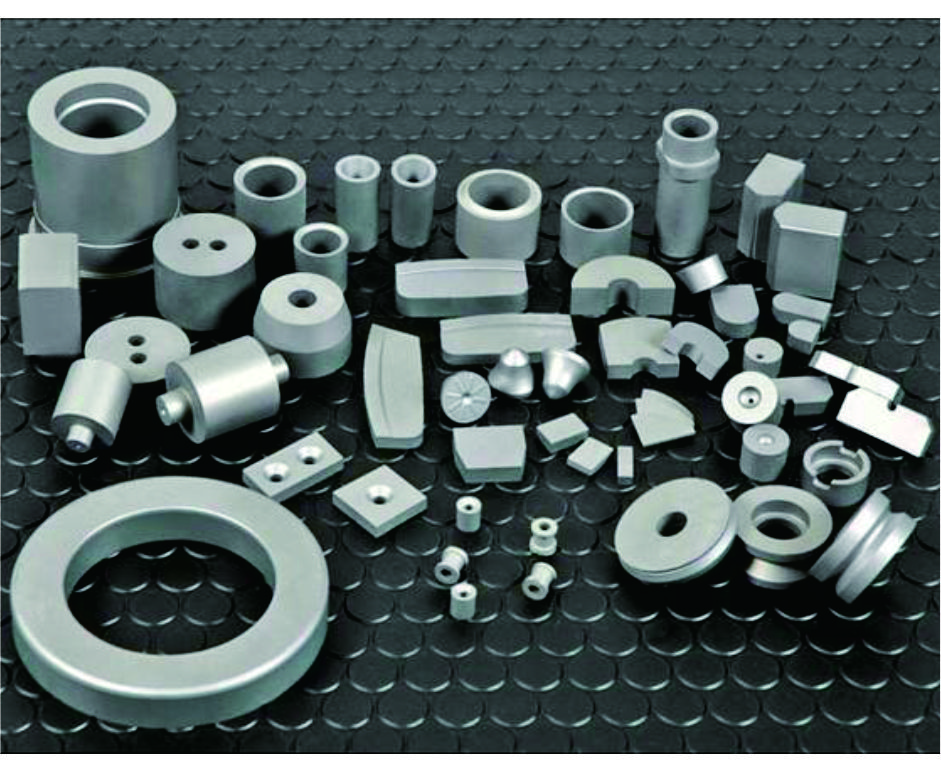

Full Series of SA-SN to cover the whole series of Carbide Burr, please turn to download page for more information.

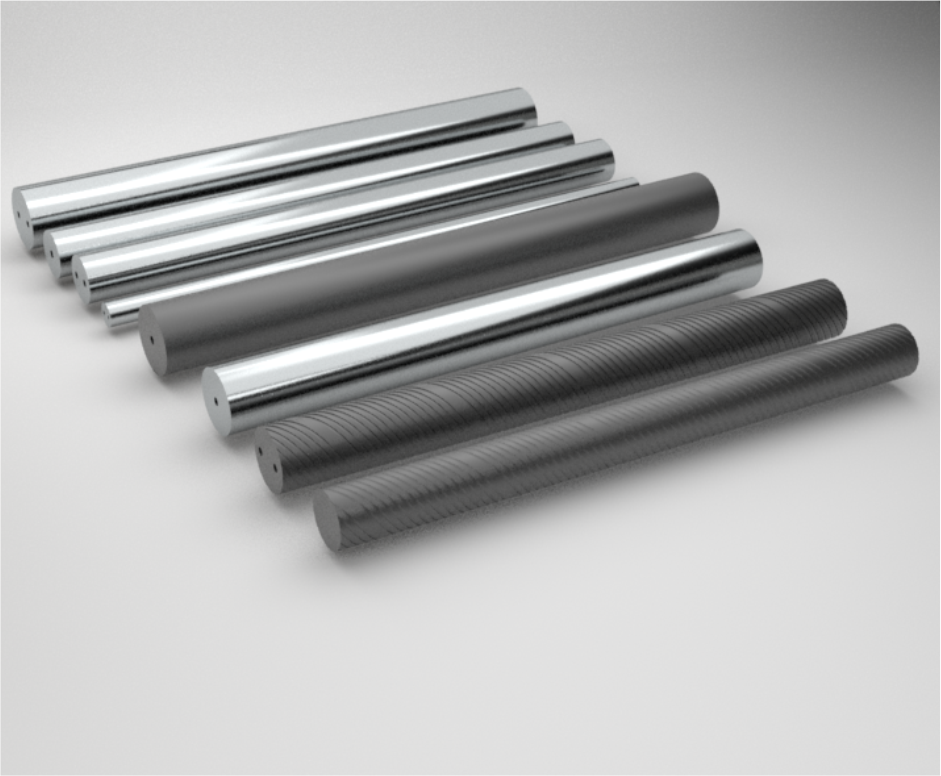

Material Property

| Carbide Grade\Property\Application | |||||

| GB Grade | I S O Grade | HRA≥ | (g/cm³)≥ | (N/mm2)≥ | Application |

| YG6X | K10 | 91.5 | 14.89 | 2870 | Suitable for producing carbide burr, especially suitable for processing non-ferrous metals and non-metallic materials. |

| YG8 | K20-K30 | 90.8 | 14.80 | 2850 | Suitable for making Dremel rotary burr. |

| FD7 | K30 | 90.8 | 14.80 | 2850 | Suitable for making Dremel rotary burr. |

| FK30 | K20-K30 | 91.6 | 14.45 | 3500 | Suitable for producing carbide burr, especially suitable for processing non-ferrous metals and non-metallic materials. |

Advantage

1.Our raw material control always adheres to high standards, and by establishing a comprehensive traceability system, we can clearly understand the source and flow of each batch of raw materials.

2.Our strict quality control is beyond imagination, and every product undergoes countless tests, inspections, and improvements in order to achieve the highest quality standards in the industry.

3.The vigorous development of the tungsten carbide industry cannot be separated from the hard work and dedication of our technical team. They study day and night and contribute their own strength to promoting technological progress in the industry.

4.Facing the challenges in the tungsten carbide industry, technological innovation is the key to breaking through the situation. The innovative research and development of superhard materials and the promotion of green production technology can create a better future.

5.The development of the tungsten carbide industry cannot be separated from the promotion of customization, meeting personalized needs, creating exclusive brand image, and expanding market space.

6.Our surface treatment technology team has gathered the wisdom and efforts of numerous experts, such as passivation treatment and sandblasting cleaning, to create excellent product surfaces.

7.Cost optimization in the industry requires continuous exploration, and we are gradually improving logistics transportation models to save transportation costs.

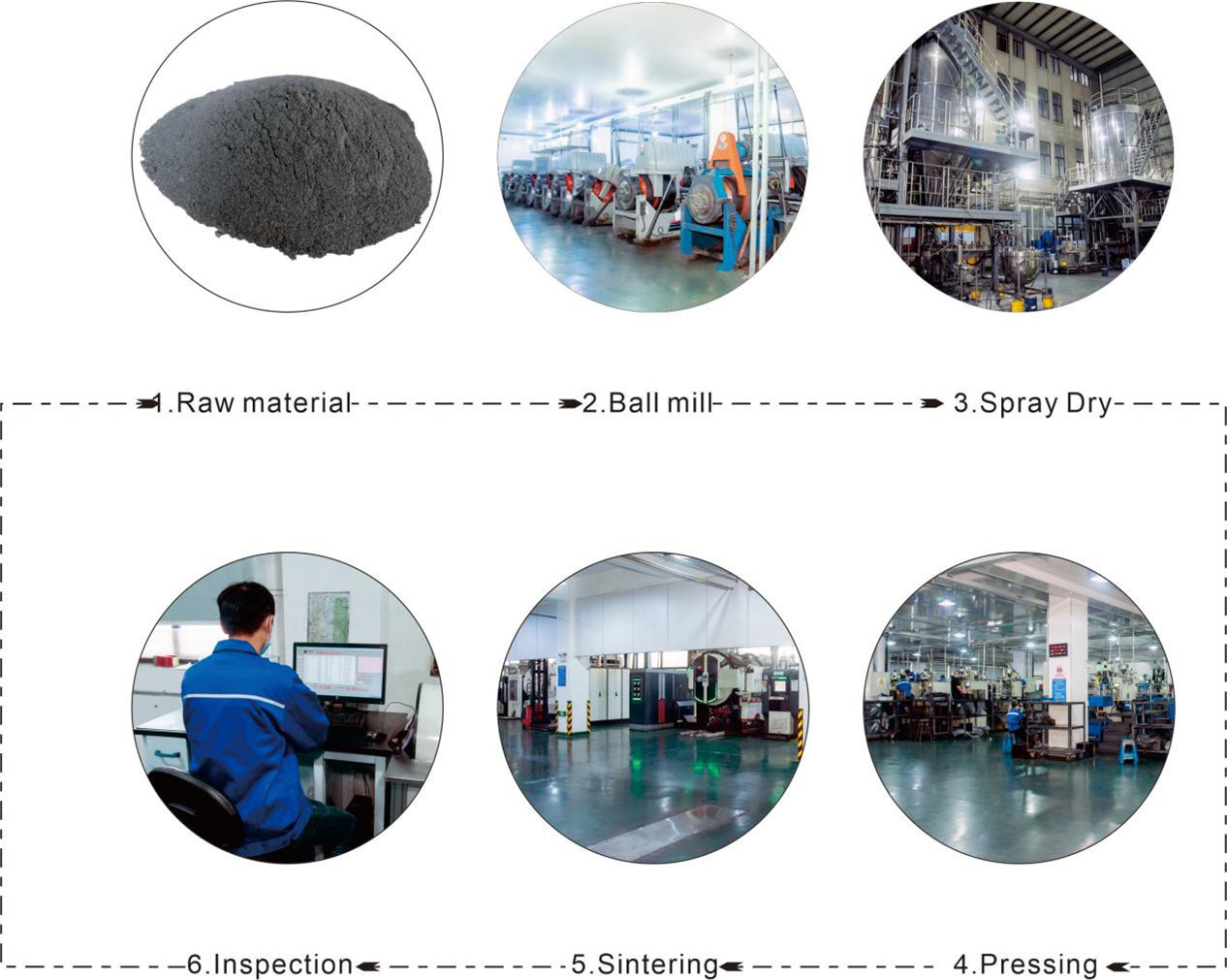

Process

Solution

Why choose us

We continuously innovate our testing methods in the tungsten carbide industry, introducing new testing methods such as laser particle size analysis to improve the accuracy and efficiency of testing.

Our production process is constantly optimized and improved by collecting and analyzing production data, identifying bottlenecks and problems in the process, continuously promoting technological and management innovation, and improving overall production efficiency.

Our suppliers are a dynamic and innovative team that continuously invests research and development resources, keeps up with market trends, and brings us a series of products with unique advantages and competitiveness, which effectively supports our business development.

Due to its proximity to Shanghai Port and Ningbo Port, the convenience of the port has become a strong support for our development. Goods can quickly go to sea and are closely connected to various parts of the world, expanding our vast commercial space.