0102030405

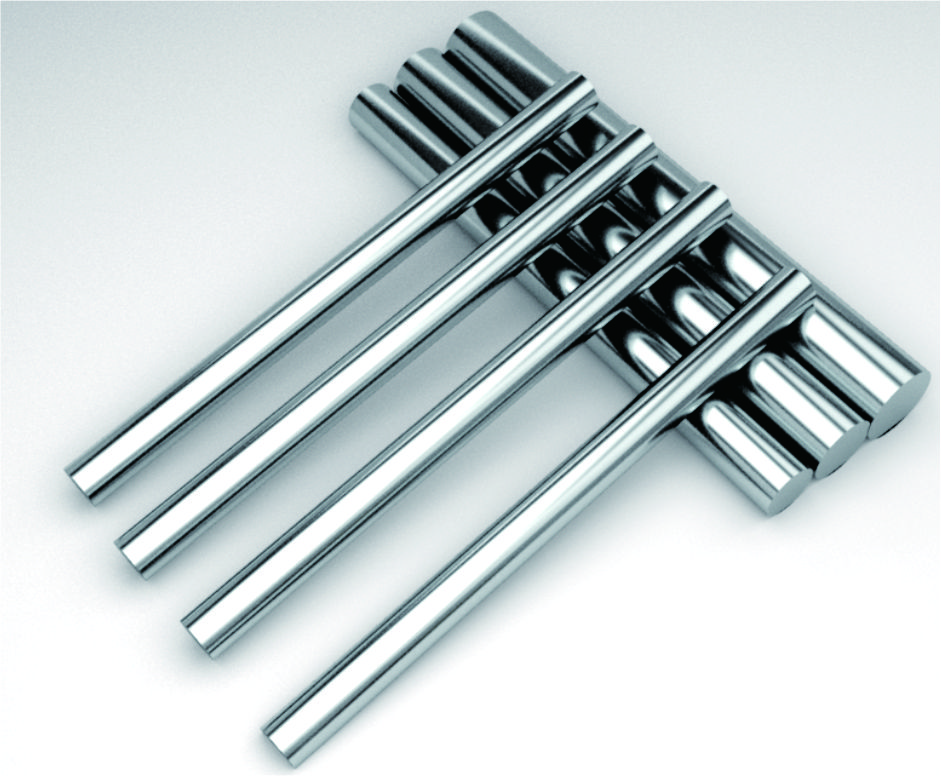

SL Type For Ball Nose Cone Shape Burr

product description

Carbide Burr Head (SL type) for Ball Nose Cone Shape Carbide Burr(Double Cut&Single Cut)

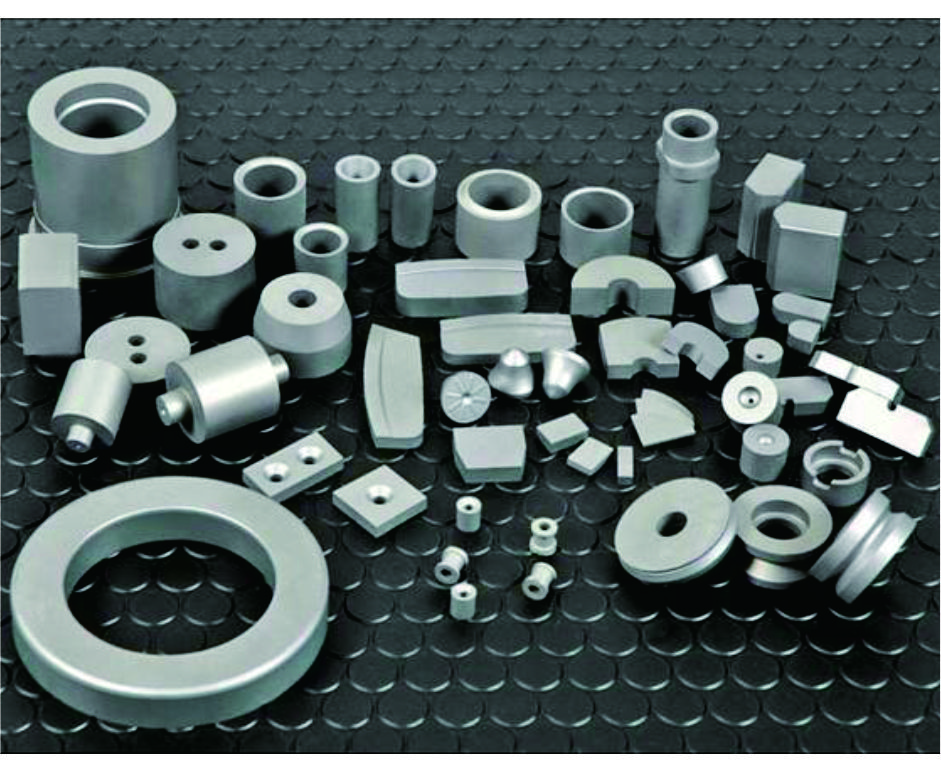

specification

Full Series of SA-SN to cover the whole series of Carbide Burr, please turn to download page for more information.

Material Property

| Carbide Grade\Property\Application | |||||

| GB Grade | I S O Grade | HRA≥ | (g/cm³)≥ | (N/mm2)≥ | Application |

| YG6X | K10 | 91.5 | 14.89 | 2870 | Suitable for producing carbide burr, especially suitable for processing non-ferrous metals and non-metallic materials. |

| YG8 | K20-K30 | 90.8 | 14.80 | 2850 | Suitable for making Dremel rotary burr. |

| FD7 | K30 | 90.8 | 14.80 | 2850 | Suitable for making Dremel rotary burr. |

| FK30 | K20-K30 | 91.6 | 14.45 | 3500 | Suitable for producing carbide burr, especially suitable for processing non-ferrous metals and non-metallic materials. |

Advantage

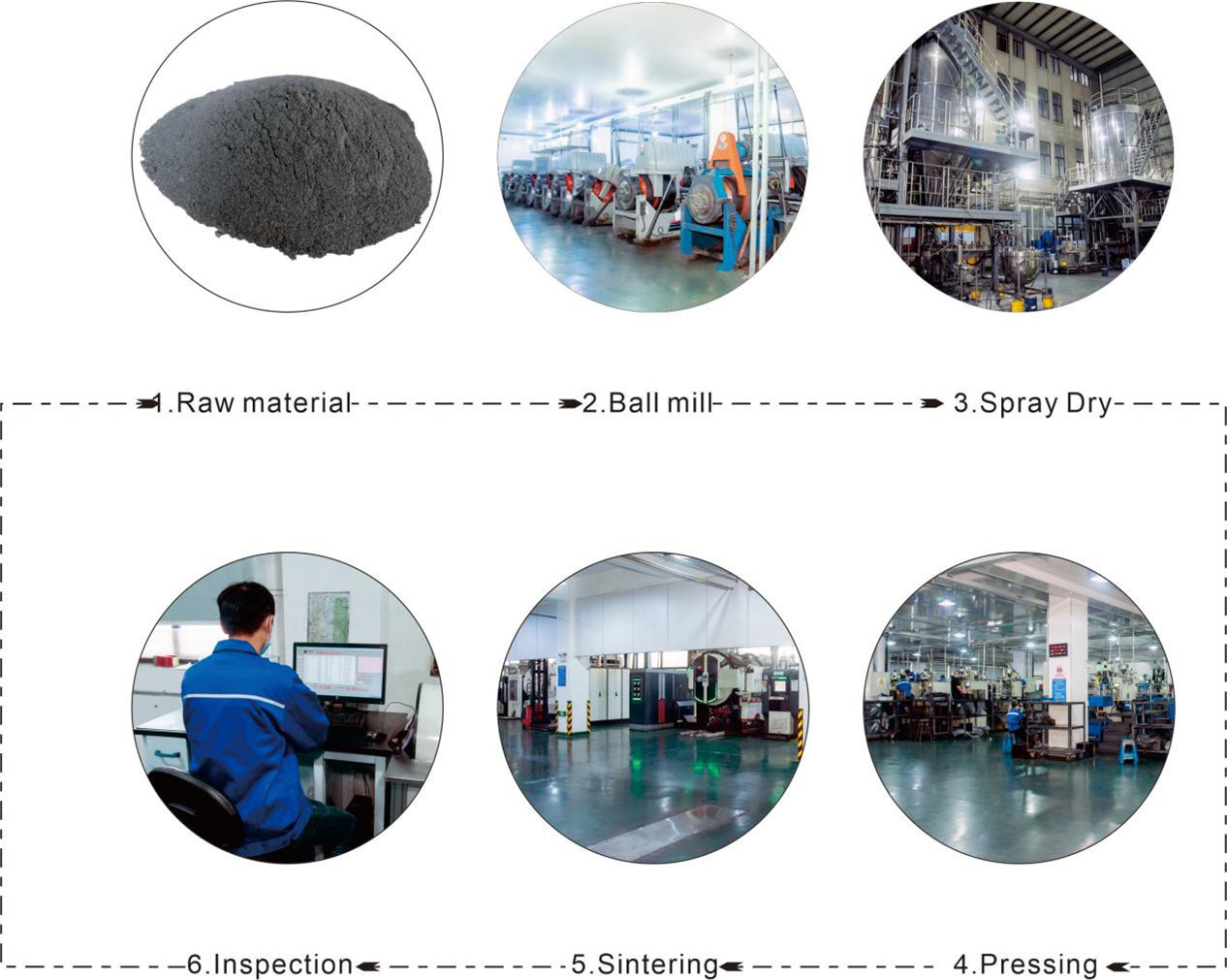

1.Our raw material control pays attention to details, not only strict requirements for the main components, but also never careless with auxiliary materials and additives.

2.Faced with fierce competition in the industry, our technical team has always maintained a high fighting spirit, driven by innovation, to create products with unique advantages.

3.Technological innovation is the core driving force for development, and the constantly emerging new methods and processes have greatly improved product performance and production efficiency.

4.Facing the challenges in the tungsten carbide industry, customization has become a breakthrough direction, accurately matching customer needs, and achieving a perfect match between products and applications.

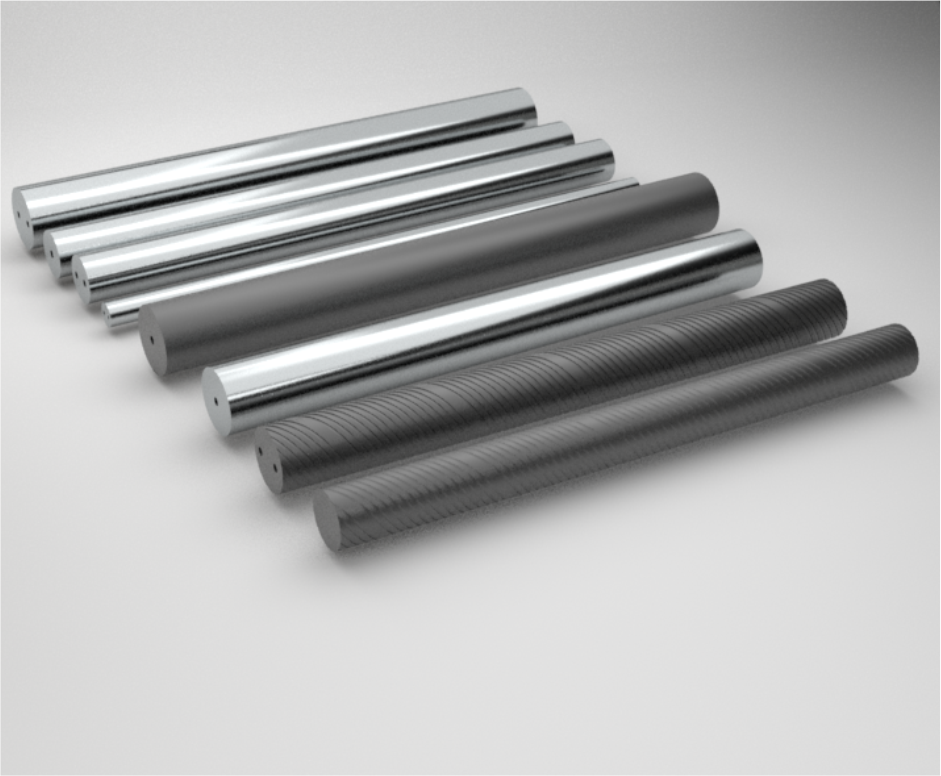

5.Our surface treatment technology continues to innovate and develop, integrating the latest technological achievements, from electrolytic polishing to sandblasting treatment, to meet various complex needs.

6.After the new production line was put into use, our monthly production capacity broke through the bottleneck and reached 50 tons, providing strong support for expanding into a broader market.

7.Cost optimization requires precise control of every link, and we strengthen inventory management to reduce inventory backlog costs.

Process

Solution

Why choose us

Our testing methods in the tungsten carbide industry follow strict standards, conducting compressive strength tests, fatigue life tests, etc., to ensure reliable product quality.

Our production process focuses on cost control, while ensuring product quality, we arrange production resources reasonably, optimize production processes, reduce raw material and energy consumption, and improve the economic benefits of the enterprise.

Our suppliers stand out in the industry with advanced automated production lines and rigorous quality inspection processes, coupled with experienced technical workers, ensuring that every batch of goods delivered to us meets or even exceeds industry standards.

The advantageous location near Shanghai Port and Ningbo Port gives us a natural advantage in port convenience. The convenient sea land intermodal transportation allows us to thrive in international trade like a fish in water.