Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

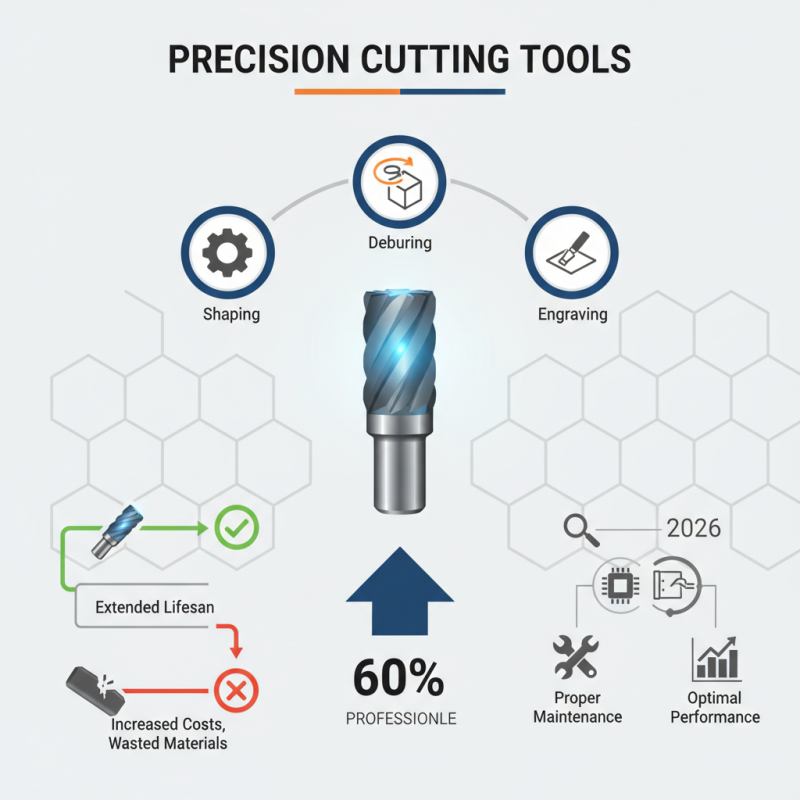

In the world of precision cutting, the Carbide Burr Tool stands out as a crucial component. According to industry reports, nearly 60% of professionals prefer carbide products for their durability and efficiency. These tools excel in shaping, deburring, and engraving various materials. However, selecting the best Carbide Burr Tool can be daunting.

The market is flooded with options, each boasting unique features and specifications. It is essential to consider the tool's application, as using an unsuitable burr can lead to inefficient results. Some users find that the performance of lower-quality tools often falls short. This discrepancy can result in increased costs and wasted materials, prompting a reconsideration of choices.

Furthermore, the evolution of carbide technology has introduced innovative designs, enhancing precision. Yet, many users overlook the importance of tool maintenance. Proper care can significantly extend a tool's lifespan, contributing to long-term savings. As we approach 2026, it is vital to stay informed about advancements that impact carbides, ensuring optimal performance in precision tasks.

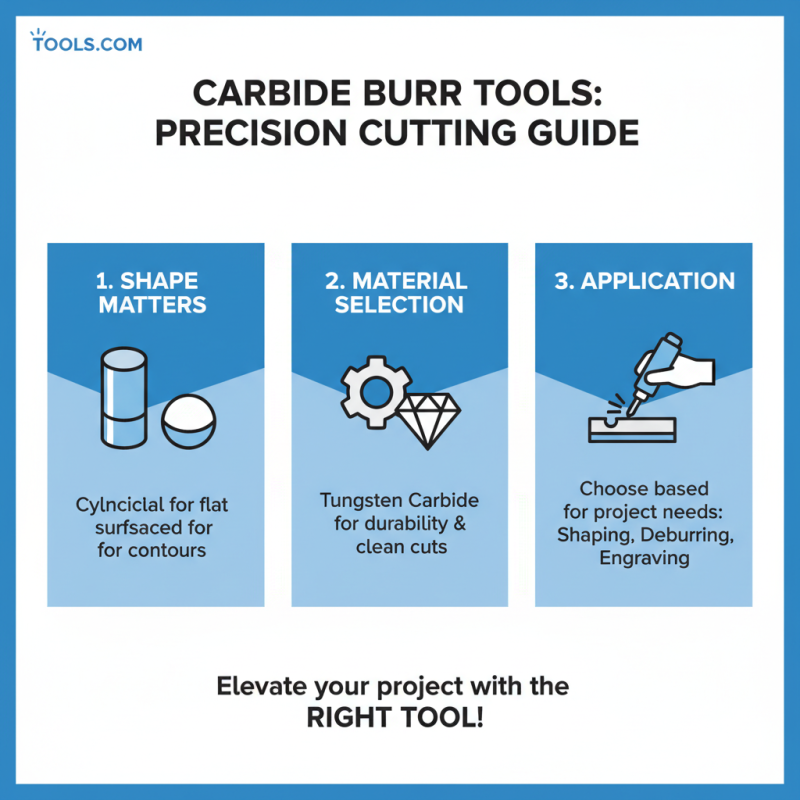

Choosing the right carbide burr tool for precision cutting can be challenging. Various factors play a role in making the best selection. First, consider the type of material you will be cutting. Different shapes and sizes of carbide burrs work better on certain materials. For example, a ball-shaped burr is ideal for machining curves and contours.

Each burr tool varies in its cutting capability. Some may leave a rough finish, while others provide a smooth cut. You should examine the grit and design of the burr. A finer grit can yield better surface quality but may be slower. Meanwhile, coarser options cut quickly but might require additional finishing work.

Evaluating your specific needs is essential. Think about the details of your project. If precise details matter, a well-designed burr is crucial. Experimenting with various options may lead to a better understanding of what works best. Keep track of your results. Reflect on what went well and what didn't. Doing so enhances your expertise in selecting the right carbide burr for your cutting tasks.

Carbide burrs are essential tools for precision cutting across various applications. They come in multiple shapes and sizes, each designed to perform specific tasks. For instance, tree-shaped burrs excel in carving and smoothing wood and plastics. Meanwhile, cylindrical burrs are perfect for shaping and grinding metal surfaces, offering versatility for machinists and hobbyists alike. According to industry reports, the global market for carbide tools is expected to grow by 5% annually, emphasizing their importance in manufacturing and repair sectors.

Choosing the right carbide burr is crucial. When using a carbide burr, speed and feed rate matter. Too high a speed can cause overheating, leading to tool wear. Conversely, too low a speed may produce subpar results. Therefore, striking a balance is key. Also, always consider the cutting material. Harder materials may require specific burr shapes to ensure efficiency and precision.

Tips: Always wear safety equipment when operating carbide burrs. A proper helmet and goggles can prevent accidents. Regularly inspect your tools for signs of wear, as worn burrs can impair cutting accuracy. Taking these simple steps can enhance your work quality and prolong tool life. Remember, continuous practice and learning from mistakes can lead to improved results.

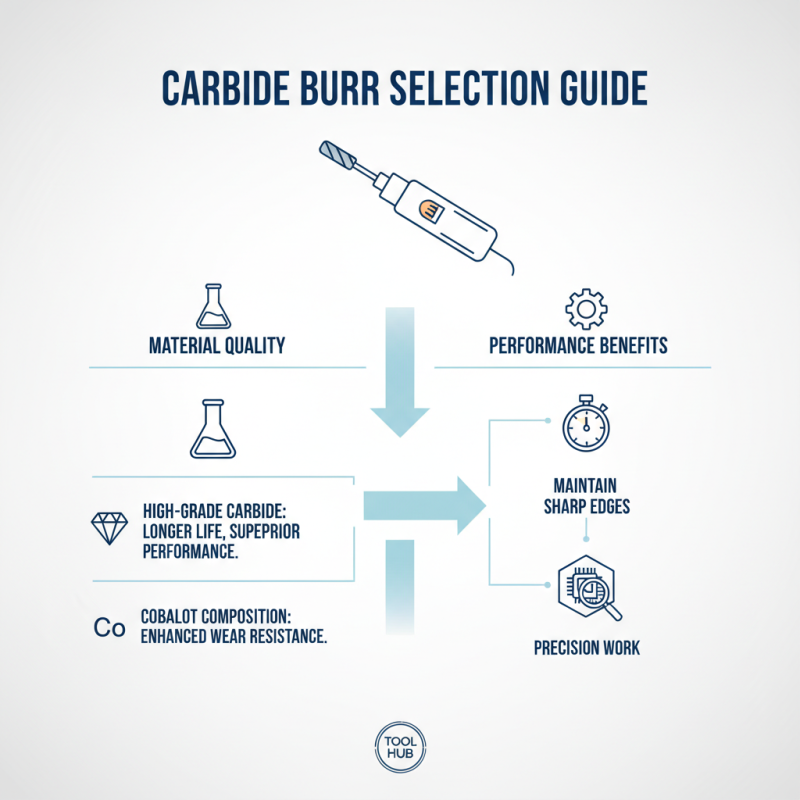

When selecting a carbide burr tool, several key features should be evaluated. The material quality is paramount. A tool made from high-grade carbide typically offers longer life and better performance. Research indicates that tools with a cobalt composition exhibit enhanced wear resistance. This means they maintain their cutting edges longer, a crucial factor in precision work.

Another essential attribute is the burr shape. Models come in various shapes like ball, flame, and cylinder. Each shape serves a specific purpose. For example, flame-shaped burrs excel at reducing material quickly. A study from the Tool Manufacturers Association shows that using the right shape can reduce machining time by up to 30%.

The diameter of the burr also impacts performance. A smaller diameter allows for intricate detail work, while a larger diameter speeds up material removal. An engineering report indicated that burrs ranging from 1/8 inch to 1/4 inch achieve optimal balance in versatility. Lastly, the shank size is vital for compatibility with different tools. Shank sizes vary, and choosing the correct one can prevent common operational issues. Users often overlook these details, leading to inefficiencies. It's worth reconsidering how these features can enhance precision cutting needs.

Proper maintenance of carbide burr tools is essential for achieving precision in cutting tasks. These tools can last long if cared for correctly. Regularly clean the burrs after use to remove debris. This helps in preventing build-up that can affect performance. For deeper cleaning, use a soft brush, ensuring no particles remain.

Storing carbide burrs in a dry, organized space can prevent damage. Avoid dropping them as impacts can chip or dull the cutting edges. Inspect your burrs regularly for signs of wear or damage. Sometimes, we overlook small nicks that can influence accuracy. A burr that seems fine may need to be replaced sooner than expected.

While using lubricant can enhance performance, applying too much can attract dust and debris. It's a fine balance. Reflecting on your usage patterns can uncover areas for improvement. Regular assessments and methodical care can extend the life of burrs significantly, leading to more effective projects.

| Burr Type | Diameter (mm) | Cutting Length (mm) | Coating Type | Ideal Material | Maintenance Tips |

|---|---|---|---|---|---|

| Cylinder | 6 | 10 | TiN Coating | Aluminum | Clean after use, avoid excessive pressure |

| Ball | 8 | 12 | Diamond Coating | Steel | Store in a dry place, inspect regularly |

| Flame | 10 | 15 | AlCr Coating | Titanium | Use with coolant, avoid heat buildup |

| Tapered | 12 | 20 | ZrO2 Coating | Plastic | Keep clean, sharpen regularly |

When choosing carbide burr tools for precision cutting, many factors come into play. Selecting the right tool is crucial for achieving clean cuts and shaping. Look for burrs with various shapes, such as cylindrical or ball-shaped, to fit specific needs. Each shape serves a different purpose, and using the right one can elevate your project.

Quality matters. Opt for tools that provide a strong grip and durability. Budget options may not always perform well. Some tools wear down quickly or chip, requiring frequent replacements. Not all burrs are suitable for every material. Understanding your material is necessary to avoid mistakes.

Test multiple tools to find the best fit. You might discover that your initial choice isn’t ideal. Experimenting enhances skills and skillful cutting. Each attempt is a learning opportunity. Precision isn't just about the tool; it also involves technique. Keep in mind that practice leads to improvement, and your toolbox can always evolve.