Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

In the world of industrial manufacturing, the use of Tungsten Carbide Tubes has become increasingly vital. These tubes are known for their hardness and resistance to wear. According to a recent study by the Material Research Institute, the market for Tungsten Carbide products is projected to grow by 7% annually. This growth highlights the significance of understanding best practices in utilizing these tubes effectively.

Expert Dr. Emily Johnson, a leading figure in materials science, emphasizes, "Optimization is key when working with Tungsten Carbide Tubes." Her insights remind us that despite their robustness, there are nuances that require attention. Successful applications often hinge on proper handling, maintenance, and installation techniques to avoid costly mistakes.

Many users overlook these critical aspects, leading to inefficiencies. For instance, improper cutting tools can lead to increased wear and tear. Similarly, neglecting environmental factors can compromise tube integrity. Understanding these details can prevent pitfalls. It's clear that while Tungsten Carbide Tubes offer numerous benefits, they demand thoughtful consideration for effective use.

Tungsten carbide tubes are known for their hardness and durability. This makes them ideal for various applications, including industrial manufacturing and mining. Understanding their properties helps in maximizing their use. These tubes can withstand extreme conditions, such as high temperatures and corrosive environments. Such resilience is crucial for effective performance.

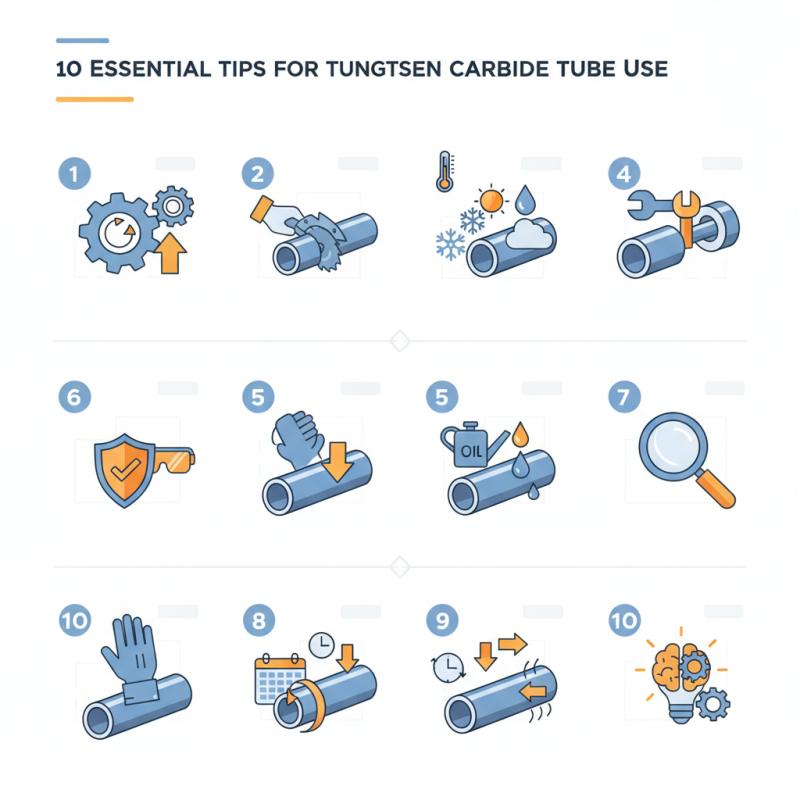

When using tungsten carbide tubes, it's essential to handle them carefully. These materials may chip or crack if dropped. Additionally, ensure proper storage to avoid exposure to moisture. Moisture can weaken the structure over time. Regular inspection helps in identifying any potential damage early on.

Another tip is to choose the right cutting tools for processing tungsten carbide. Not all tools work well with this material. Some can wear out quickly. Be mindful of the compatibility between tools and the carbide. Understanding these aspects can contribute significantly to efficiency and longevity.

Choosing the right tungsten carbide tube for your project can be challenging. There are several factors to consider. First, think about the dimensions. The diameter and length need to fit your specific application. Incorrect sizing can lead to poor performance and wasted resources.

When selecting a tungsten carbide tube, consider its intended use. For high-temperature applications, ensure the tube can withstand extreme conditions. Check for the hardness rating. This can impact durability and effectiveness. If you choose a tube that doesn’t meet these criteria, it might fail during critical tasks.

Here are a few tips. Always measure accurately before purchasing. Mistakes in measurements can lead to incorrect purchases. Don’t hesitate to reach out to experienced users for advice. They often provide insights that can save you time and money. Lastly, consider experimenting with different options. Every project is unique, so flexibility can lead to better results. Remember, learning from failures is part of the process.

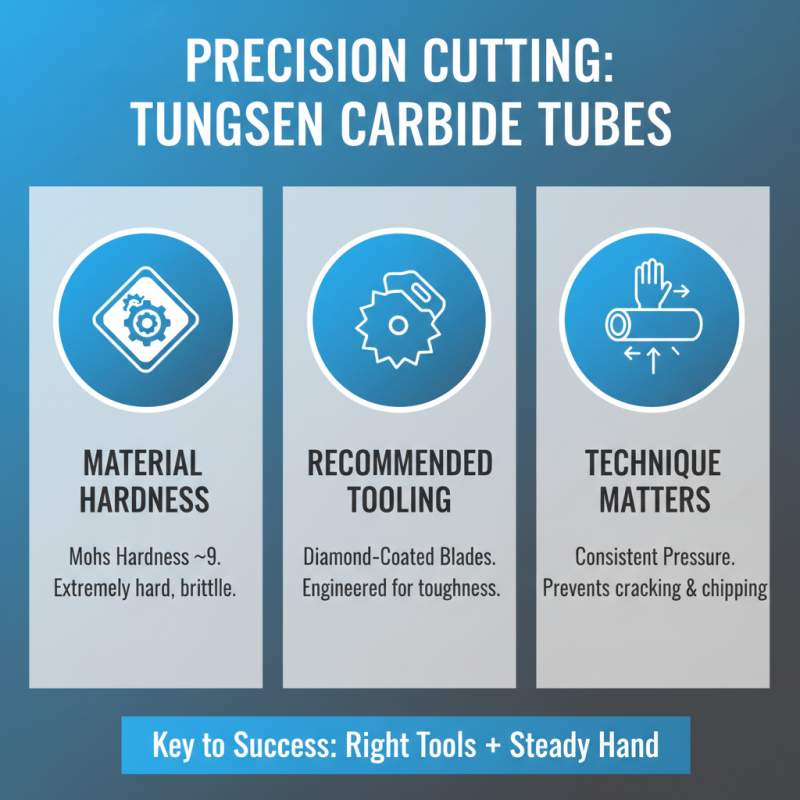

When cutting tungsten carbide tubes, precision is key. The material is incredibly hard, with a hardness rating around 9 on the Mohs scale. This makes it challenging to shape. Using the right tools is essential. Diamond-coated blades are often recommended. They can handle the toughness of the material effectively. Make sure to apply consistent pressure during the cutting process. Uneven pressure can lead to cracking or chipping.

Shaping tungsten carbide requires careful planning. It is advisable to heat the tube before shaping. Heating can relieve internal stresses and make the material easier to work with. According to recent industry reports, proper heating can reduce breakage rates by up to 30%. Keep in mind, though, that overheating can lead to structural weaknesses. Monitor the temperature closely. Use a thermocouple for accurate readings.

Finishing processes are equally important. After cutting and shaping, a proper polishing technique will enhance the surface finish. However, beginners often overlook this step. Neglecting polishing can result in a rough surface, reducing the component's performance. Some experts suggest using ultrasonic cleaning after shaping. This can remove debris and ensure a smooth finish. Remember, every step in this process impacts the final product.

Tungsten carbide tubes are widely used due to their exceptional hardness and resistance to wear. However, finishing and polishing these tubes can be challenging. Proper techniques are essential to achieving a smooth surface that meets industry standards.

When polishing tungsten carbide, vibration-assisted techniques can yield excellent results. A study by the Journal of Materials Science indicated that this method enhances surface quality significantly. Experiment with different polishing compounds. Fine abrasives can help reduce surface roughness. The ideal grit size varies, but something around 600-800 is a good starting point.

Maintain a consistent pressure during the process. Uneven pressure can lead to imbalances and noticeable flaws. Regularly check the surface for any inconsistencies. If defects appear, reassess your technique. It’s worth noting that achieving a flawless finish is often trial and error. Sometimes, you may have to go back several steps. Don’t rush; patience is key.

Using protective gear is crucial. Tungsten carbide dust can be harmful if inhaled. Ensure your workspace is well-ventilated. Automation tools are helpful, but they require careful calibration. Poorly calibrated tools can create more problems than they solve. Keep your equipment clean to avoid contamination. Regular maintenance on polishing tools will ensure longevity and optimal performance.

Proper maintenance and storage of tungsten carbide tubes are vital for their longevity and performance. Regular cleaning is necessary. Residues can accumulate and impact their functionality. In a study by the American Society of Mechanical Engineers, effective cleaning practices can extend the life of these tubes by up to 30%. Always use appropriate cleaning agents to avoid damage.

Storage conditions are equally important. Tungsten carbide tubes should be kept in a dry, cool place. Humidity can lead to corrosion, affecting their durability. The report from the International Journal of Materials Science emphasizes that storing in optimal conditions can prolong the life of these tools significantly. Additionally, avoid stacking them to prevent physical damage. Even a small dent can compromise their effectiveness.

Consider maintaining an inventory system to track usage and condition. This approach reduces the chances of overlooking damaged tools. Inspection should happen regularly. Despite all precautions, wear and tear are inevitable. A meticulous inspection routine can help identify issues before they escalate. Even high-quality tungsten carbide tubes deserve attention and care to ensure peak performance.

This chart illustrates the importance level of various tips for effectively using and maintaining tungsten carbide tubes. Each tip is rated on a scale from 1 to 10, emphasizing the essential practices for longevity and performance.