010203

Carbide Inserts(FM10 Type) For Coal Mining Tools

product description

Cemented carbide inserts(FM10) for Coal Mining Tools

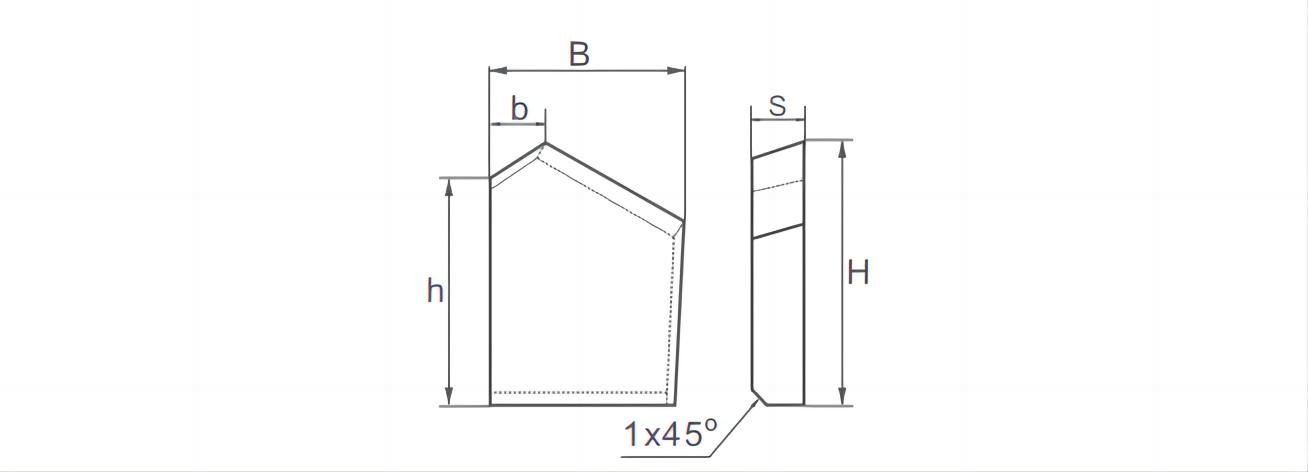

specification

| TYPE | B | H | S | b |

| FM1011 | 11.0 | 12.0 | 2.5 | 4.0 |

| FM1014 | 14.0 | 19.0 | 3.8 | 4.0 |

| FM1015 | 15.0 | 22.0 | 3.0 | 5.0 |

| FM1018 | 18.0 | 22.0 | 6.0 | 5.0 |

Material Property

| Carbide Grade\Property\Application | |||||

| GB Grade | I S OGrade | HRA≥ | (g/cm³)≥ | (N/mm2)≥ | Application |

| FD05E | - | 87.8 | 14.95 | 2500 | Extra coarse grain size, suitable for milling and shaping teeth in cement road repair. |

| FD10E | - | 87.6 | 14.90 | 2700 | Extra coarse grain size, suitable for milling teeth in asphalt road repair. |

| FD05A | G05 | 90.5 | 14.93 | 3000 | Suitable for making button bit,DTH button bit. |

| FD15 | G15 | 88.9 | 14.71 | 2870 | Suitable for making button bit,DTH button bit. |

| FD40E | G40 | 85.8 | 14.30 | 2800 | 。 Extra coarse grain size, suitable for making coal mining teeth. |

| YG8 | G10 | 90.3 | 14.73 | 2950 | Suitable for geological exploration and coal mining. Drilling into coal seams without silicified shale potassium salts. Rock salt and other homogeneous rocks. It is also suitable for medium hard sandstone, limestone, and rocks with alternating softness and hardness. |

| YG95 | - | 87.9 | 14.58 | 2650 | Suitable for impact rotary drill bits, including drill bits, buttons, and drilling hard and hard layers. Also applicable to construction drill bit. |

| YG11C | - | 87.2 | 14.40 | 2730 | Suitable for drill bits with impact and rotation, as well as mining cone drills, ball teeth, and drilling hard and hard layers. Also applicable to construction drill bits. |

| YG13C | G30 | 86.7 | 14.18 | 2850 | 。 Suitable for making tri-cone bits and coal mining teeth. |

| YG16C | - | 85.8 | 13.85 | 2950 | Suitable for manufacturing oil-field tri-cone bit and diamond composite disc bases. |

Advantage

1.We have set a special part number for each batch of materials and record it on a card. During the production process, this part number card flows through the process, and any quality problems found can be traced back to the source.

2.We always adhere to the ultimate pursuit of quality, with a rigorous attitude and meticulous processes, to carry out strict quality control, and never miss any subtle point that may affect product quality.

3.Experienced technology team to guarantee the production process,average >13 years experience covering:Powder Mixing,Pressing,Sintering,Moulding,Lab.

4.We constantly innovate in technology, work together with excellent partners to overcome technical difficulties and promote industry progress.

5.We are committed to providing diverse and customized services to meet the unique and constantly changing needs of every customer, in order to create a unique experience.

6.With advanced equipment and an efficient team, our company has successfully achieved the monthly production capacity target of 50 tons, laying a solid foundation for the continuous growth of our business.

7.We strengthen the management of raw material procurement, establish long-term cooperation with high-quality suppliers, strive for more favorable prices and payment terms, and effectively control production costs.

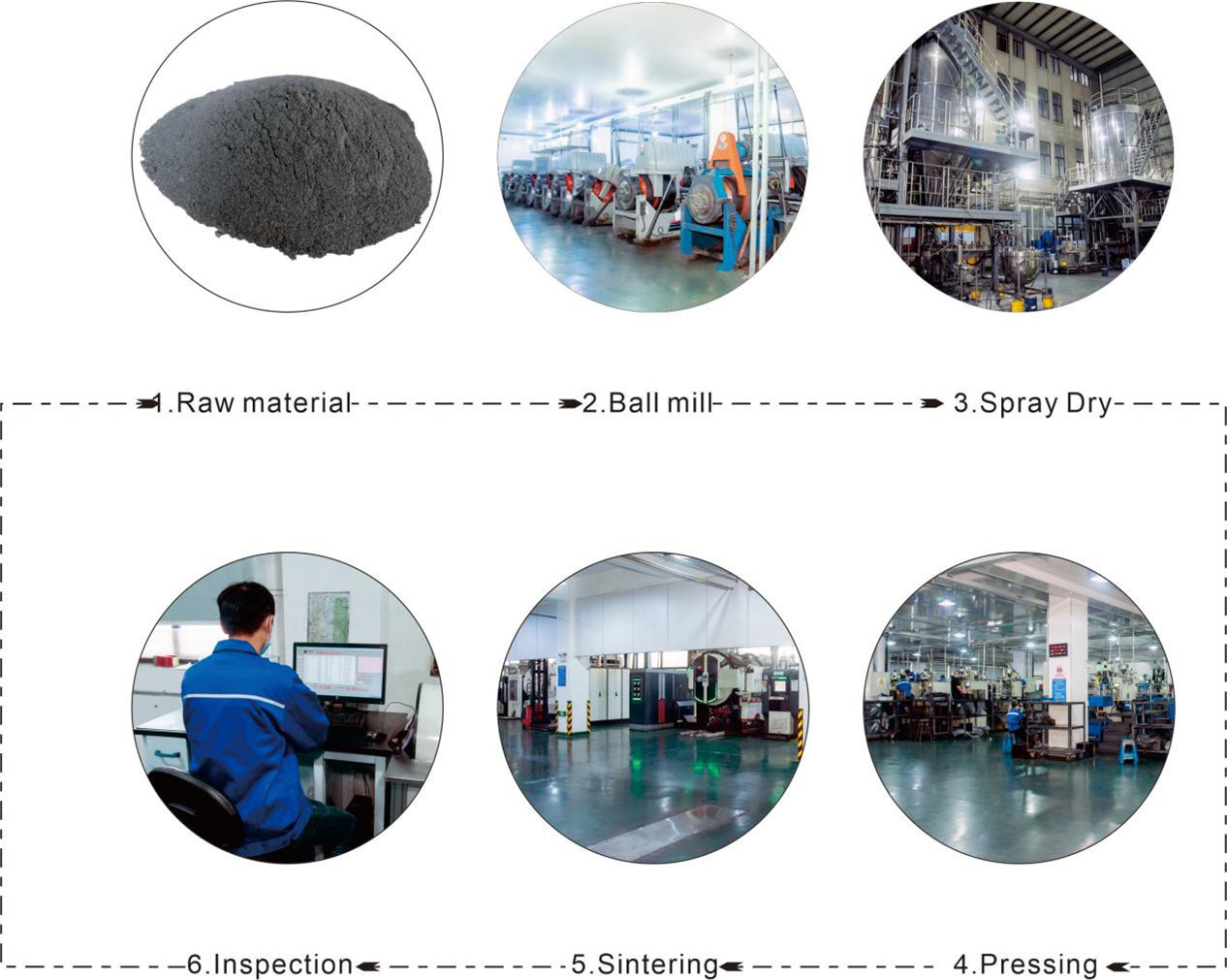

Process

Solution

Why choose us

We conduct comprehensive testing and evaluation of all relevant indicators and performance of the product.

Based on our accumulated experience, we continuously optimize the production process, improve production efficiency and product quality through reasonable arrangement of processes and resource allocation.

Our suppliers have large-scale production bases and highly automated production lines, which can achieve large-scale, efficient, and low-cost production, providing customers with highly competitive prices and stable supply.

We have gained strength due to our proximity to Shanghai Port and Ningbo Port. The convenient transportation and complete logistics facilities at the ports provide strong support and guarantee for our product exports.